10 Best Carbon Nanotube (CNT) Products to Explore in 2025

Modern industries increasingly rely on advanced materials to drive innovation and efficiency. Among these, carbon nanotubes (CNTs) have emerged as a transformative material due to their exceptional mechanical strength, lightweight nature, and outstanding electrical and thermal conductivity. From energy storage to electronics and aerospace, CNTs are making their mark in various cutting-edge fields.

If you are exploring advanced materials for research or industrial applications, this guide to the 10 best carbon nanotube products in 2025 will help you identify solutions that align with your goals.

What Are Carbon Nanotubes?

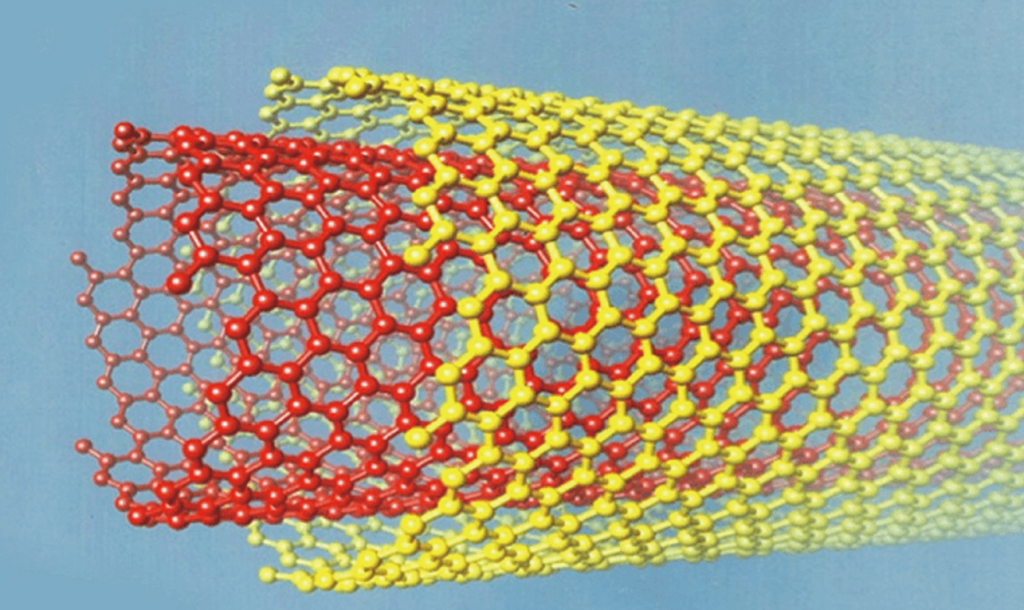

Carbon nanotubes (CNTs) are nanoscale cylindrical structures composed entirely of carbon atoms arranged in a hexagonal lattice. These tubes, typically a few nanometers in diameter but extending to micrometers or even millimeters in length, exhibit remarkable properties that make them highly versatile in advanced applications.

Key types of CNTs include:

- Single-Walled Carbon Nanotubes (SWCNTs): Composed of a single layer of graphene rolled into a cylinder, SWCNTs are prized for their precise electronic properties and are widely used in electronics, sensors, and nanomedicine.

- Multi-Walled Carbon Nanotubes (MWCNTs): These consist of multiple concentric layers of graphene, providing higher mechanical strength and making them ideal for industrial-scale applications, such as composites and structural materials.

Key Features of Carbon Nanotube Products

When selecting carbon nanotube products, understanding their key properties and features is essential for determining their suitability for specific applications:

- Purity Level: The higher the purity, the better the performance in high-precision and sensitive applications.

- Diameter and Length: These parameters influence electrical, mechanical, and thermal properties, and vary according to application needs.

- Surface Functionalization: Functionalized CNTs with added chemical groups improve their compatibility with polymers, solvents, or other matrices.

- Conductivity: Exceptional electrical and thermal conductivity make CNTs a popular choice in energy and electronic applications.

- Dispersibility: Easily dispersible CNTs are vital for applications requiring uniform distribution, such as coatings and composite materials.

10 Best Carbon Nanotube Products to Explore in 2025

#1. Industrial-Grade Multi-Walled CNTs

Overview: Industrial-grade MWCNTs are widely used for enhancing material properties in various large-scale applications. Their robustness and cost-effectiveness make them a preferred choice for bulk production needs.

Key Features:

- Diameter: 10-20 nm

- Length: 10-30 μm

- Purity: >95%

- Applications: Structural reinforcement, thermal interface materials, EMI shielding, and plastic composites.

Why Choose This Product? Industrial-grade CNTs are the backbone of high-performance composites in industries like construction, automotive, and electronics.

#2. High-Purity Single-Walled CNTs (SWCNTs)

Overview: SWCNTs are the gold standard for precision applications requiring exceptional electronic or optical properties. These nanotubes provide unparalleled performance for researchers and high-tech manufacturers.

Key Features:

- Diameter: 1-2 nm

- Length: 5-20 μm

- Purity: >99%

- Applications: Transistors, sensors, nano-optics, and quantum dots.

Why Choose This Product? SWCNTs’ extraordinary electrical conductivity and high aspect ratio make them indispensable for innovations in nanotechnology and flexible electronics.

#3. Functionalized CNTs

Overview: Functionalized CNTs are modified with chemical groups such as hydroxyl, carboxyl, or amine to enhance compatibility with polymers, solvents, or specific chemical environments.

Key Features:

- Surface Functional Groups: –OH, –COOH, or –NH2

- Applications: Drug delivery, polymer composites, advanced coatings, and biomedicine.

Why Choose This Product? Functionalized CNTs offer superior dispersibility and tailored functionality for specialized applications.

#4. Aligned CNT Arrays

Overview: Aligned CNTs are specifically engineered for applications requiring directional properties, such as heat conduction and electromagnetic shielding.

Key Features:

- Alignment: High-density vertical or horizontal arrangement

- Applications: Thermal interface materials, sensors, and transistors.

Why Choose This Product? Aligned CNT arrays ensure maximum efficiency in heat transfer and energy applications, particularly in electronics and optoelectronics.

#5. CNT-Based Conductive Inks

Overview: CNT conductive inks are revolutionizing the printed electronics industry, offering high conductivity and flexibility for creating advanced electronic components.

Key Features:

- Low Resistance: Optimized for electrical performance

- Applications: Flexible electronics, RFID tags, and touchscreens.

Why Choose This Product? These inks simplify the production of lightweight, flexible, and highly efficient circuits for next-generation devices.

#6. CNT-Reinforced Composites

Overview: CNT composites provide exceptional strength-to-weight ratios and durability, making them ideal for aerospace, automotive, and industrial applications.

Key Features:

- Tensile Strength: Significantly enhanced

- Applications: Aircraft parts, automotive panels, and construction materials.

Why Choose This Product? CNT composites excel in scenarios where strength, weight reduction, and thermal stability are critical.

#7. CNT Powders for Energy Storage

Overview: CNT powders are optimized for energy storage systems, including lithium-ion batteries and supercapacitors, to improve energy density and lifespan.

Key Features:

- Specific Surface Area: High surface area for better charge storage

- Applications: Battery electrodes, capacitors, and fuel cells.

Why Choose This Product? With the demand for efficient energy storage surging, CNT powders offer unmatched performance enhancements.

#8. CNT-Based Filters

Overview: CNT filters leverage nanoscale porosity for water purification, gas separation, and other filtration systems, ensuring efficiency and environmental sustainability.

Key Features:

- Pore Size: Nano-scale filtration capabilities

- Applications: Clean water technology, air purification, and industrial separation processes.

Why Choose This Product? CNT filters are essential for industries aiming to meet strict environmental standards while optimizing performance.

#9. CNT Coatings

Overview: CNT coatings enhance durability, corrosion resistance, and conductivity, making them valuable for industrial and consumer applications.

Key Features:

- Uniform Dispersion: Ensures consistent performance

- Applications: Anti-corrosion layers, conductive coatings, and sensor integration.

Why Choose This Product? CNT coatings provide multi-functional benefits, extending the lifespan and utility of materials.

#10. CNT Yarn and Fibers

Overview: CNT yarns combine flexibility with high tensile strength, opening up possibilities in textiles, smart fabrics, and advanced structural materials.

Key Features:

- Strength: Superior to traditional fibers

- Applications: Wearable electronics, industrial textiles, and aerospace materials.

Why Choose This Product? CNT yarns enable the development of futuristic, high-performance fabrics and components.

Why Invest in Carbon Nanotubes in 2025?

The global carbon nanotube market is expanding rapidly, driven by the need for sustainable, high-performance materials across industries like energy, electronics, and healthcare. With applications ranging from flexible displays to water purification, CNTs are poised to shape the future of technology and innovation.

Are you ready to leverage the potential of carbon nanotubes? Contact us today to explore these products and discover customized solutions tailored to your research or industrial needs.