3D Printed Graphene Oxide Nanocomposite Aerogel for Intelligent Fire Warning and Fireproofing

Background With the accelerated urbanization and the rise of high-rise buildings, fire safety and prevention have become critical issues in modern society. Traditional fire alarm sensors often respond too slowly to meet the demands of rapid fire suppression and rescue operations. Moreover, conventional methods of aerogel preparation lack flexibility in structure and shape customization, hindering personalized applications. Therefore, developing intelligent fire warning aerogels with controllable 3D structures and shapes is of great theoretical and practical value.

Overview Researchers from Nanjing Forestry University, led by Tongtong Ma, employed direct ink writing (DIW) 3D printing technology to develop a high-fidelity, porous, intelligent fire warning aerogel. This aerogel is composed of graphene oxide (GO), cellulose nanofibers (CNF), and ammonium polyphosphate (APP). Findings indicate that ink containing 20% CNF (GA-CNF-20) possesses a dynamic yield stress of 620 kPa, enabling the printed aerogel to exhibit an elastic modulus of 153 kPa and a compressive stress of 400 kPa at 39.7% deformation. Additionally, GA-CNF-20 demonstrated an ultra-fast warning trigger time of 1.32 seconds and a long-term response time of 170 seconds under fire conditions. The aerogel also boasts excellent thermal insulation, high char formation, self-extinguishing properties, and structural integrity during combustion tests.

Visual Guide

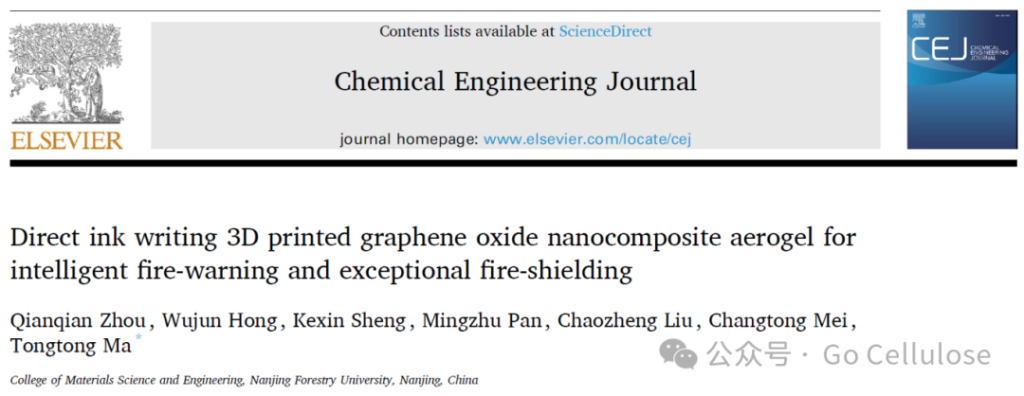

- 3D Printed Layered Porous GO Aerogel Figure 1 illustrates the design and fabrication process of the GO-based aerogel. Initially, cellulose nanofibers (CNF) are mixed with APP and GO solutions to form an ink with desirable rheological properties. This ink is then used for DIW 3D printing, followed by freeze-drying to create GO-based aerogels of various shapes and thicknesses. Finally, through in-situ phosphorus doping reactions involving APP, the GO aerogel is transfor

- med into reduced graphene oxide (RGO) aerogels with superior fire warning and fireproofing properties.

Figure 1: Schematic of the 3D printing strategy for layered porous GO aerogels.

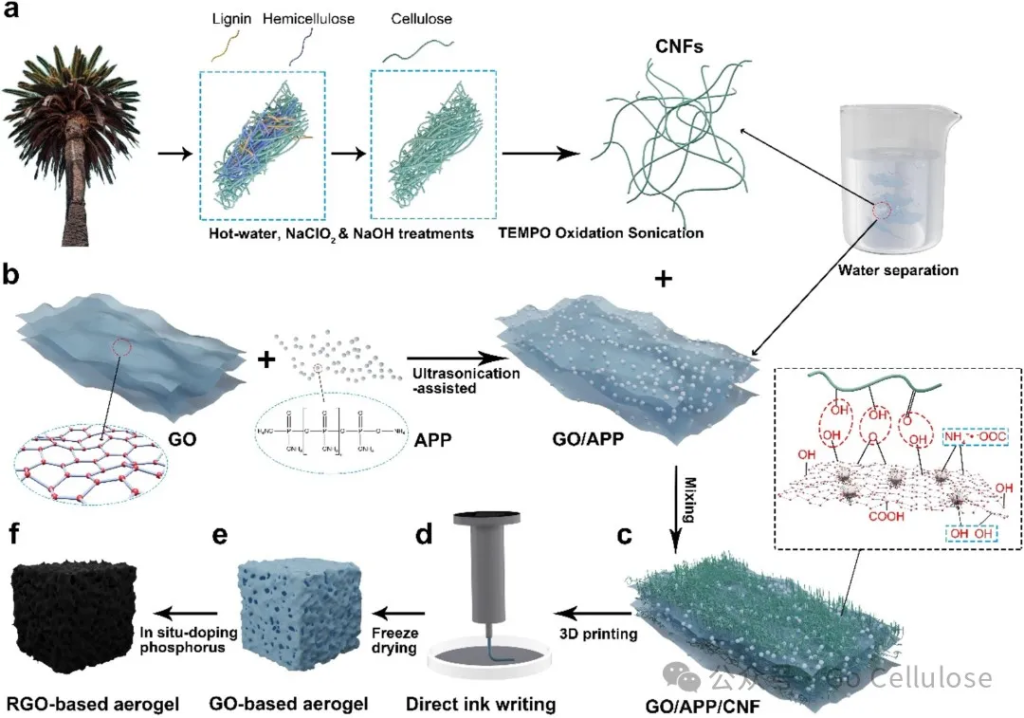

- Structural Characterization Figure 2 presents the chemical composition and structural features of GO, CNF, APP, and GO-based aerogels through FTIR, XRD, and XPS analyses. The findings show that CNF promotes the dispersion of GO nanosheets and forms hydrogen bonds, enhancing the aerogel’s structural stability and mechanical properties. The inclusion of APP contributes to the dispersion of phosphorus elements, laying the foundation for an intumescent flame retardant (IFR) system.

Figure 2: (a) FTIR spectra; (b) XRD curves; (c-e) XPS results of GA-CNF-0 and GA-CNF-20.

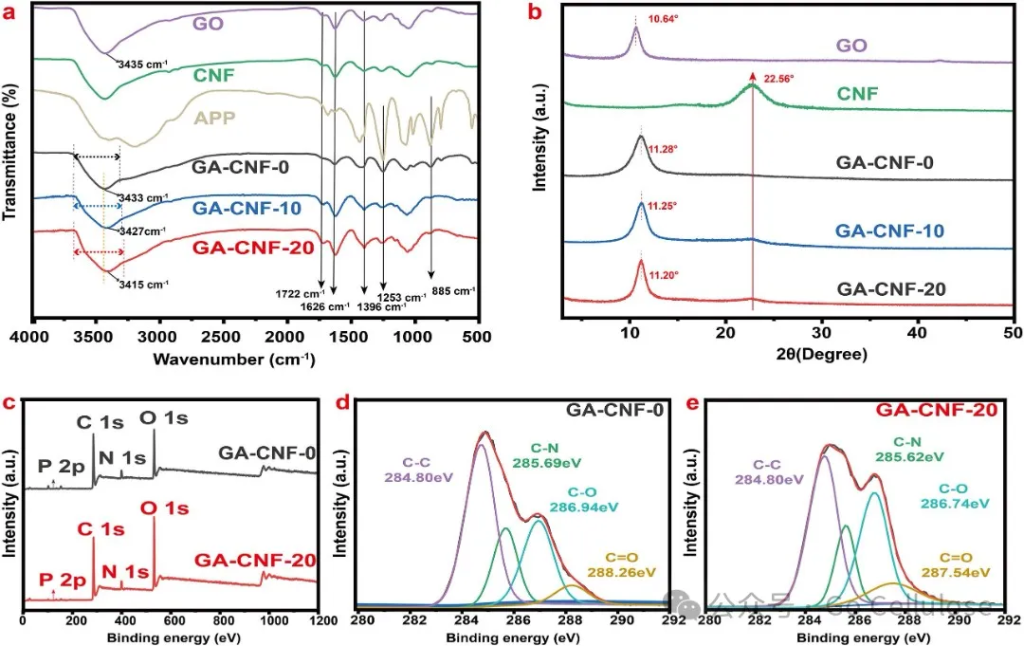

- Morphology and Hydrogen Bond Energy Figure 3 shows the morphology of CNF, GO, and GO-based ink. The CNF exhibits a web-like structure, while GO appears as sheets. The GO-based ink demonstrates uniform dispersion of GO nanosheets and APP particles, and strong hydrogen bonding interactions between APP particles and CNF nanofibers are observed. DFT calculations confirm these interactions, highlighting CNF’s role in improving the rheological properties and structural stability of the GO-based ink.

- 3: TEM images of (a) CNF, (b) GO, (c) GA-CNF-0, and (d) GA-CNF-20; (e-f) Geometric shape and hydrogenbond energy of GA-CNF-0 and GA-CNF-20.

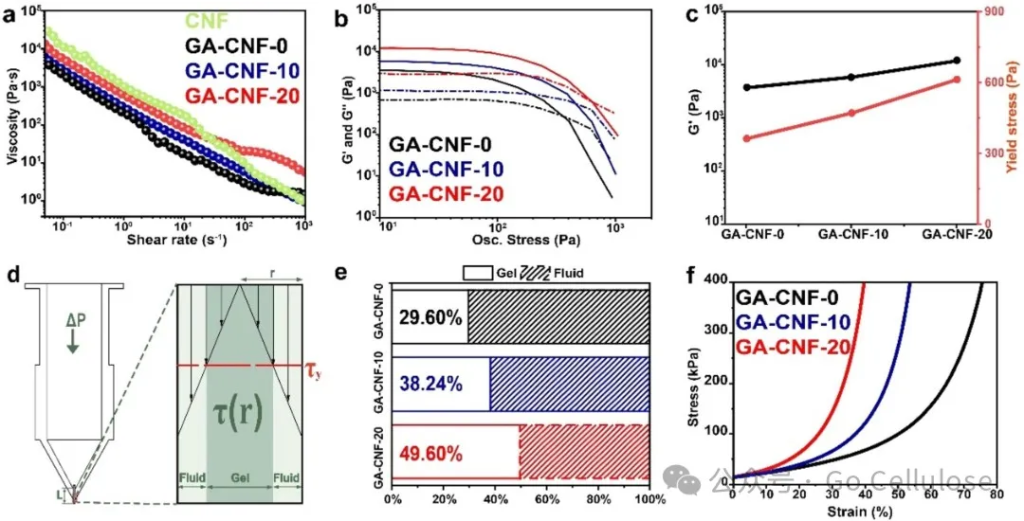

- Rheological and Mechanical Properties Figure 4 systematically studies the rheological properties of GO-based inks and their relationship with 3D printing performance and mechanical properties. Results indicate that the addition of CNF significantly enhances the viscosity, storage modulus, and yield stress of the ink, ensuring stable flow during 3D printing and high shape fidelity of printed samples. The inclusion of CNF also improves the compressive strength and elastic modulus of the aerogel, yielding superior mechanical performance.

Figure 4: Rheological characteristics and 3D printability of the ink.

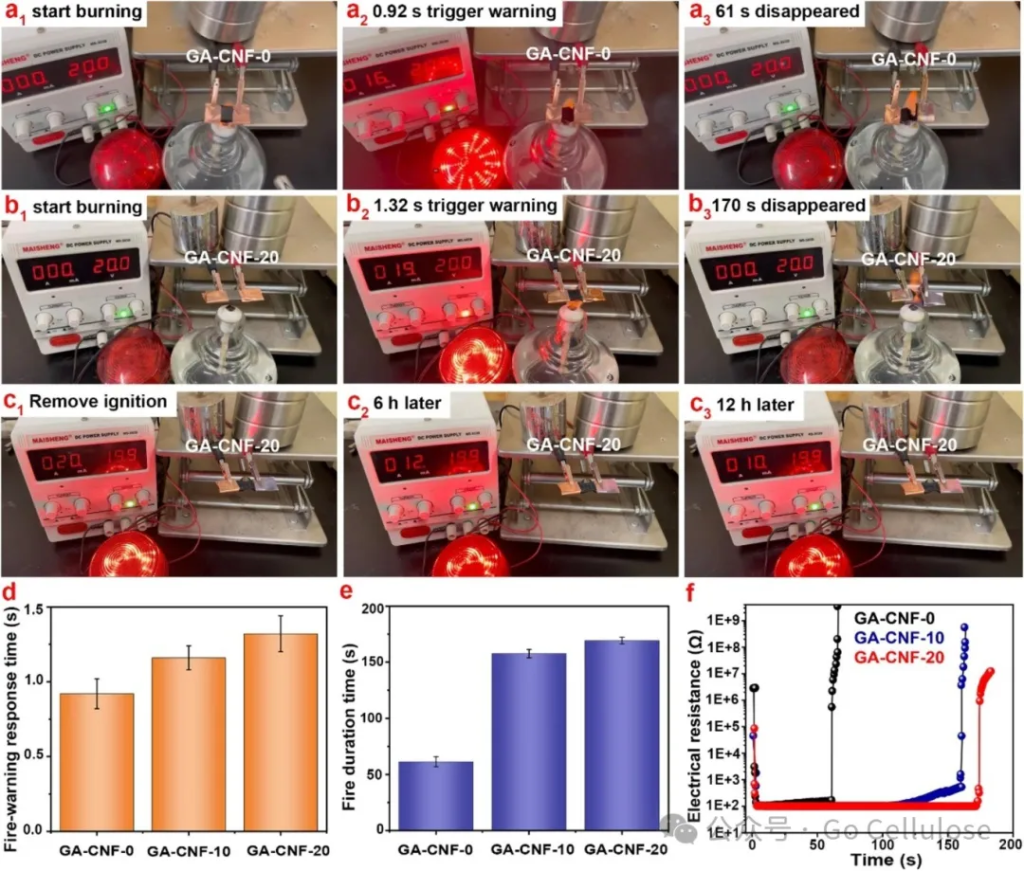

Figure 4: Rheological characteristics and 3D printability of the ink. - Early Fire Warning Behavior Figure 5 showcases the fire warning behavior of different GO-based aerogels. The findings reveal that upon exposure to flame, the GO-based aerogels can swiftly trigger fire warning signals, with a short warning time (1.32 seconds) and a long response time (170 seconds). This is attributed to the in-situ phosphorus doping reaction of APP at high temperatures, forming a conductive phosphorized carbon layer that maintains continuous fire warning signals. Compared to GA-CNF-0, GA-CNF-20 shows longer warning duration and enhanced fireproofing properties.

Figure 5: Fire warning test process.

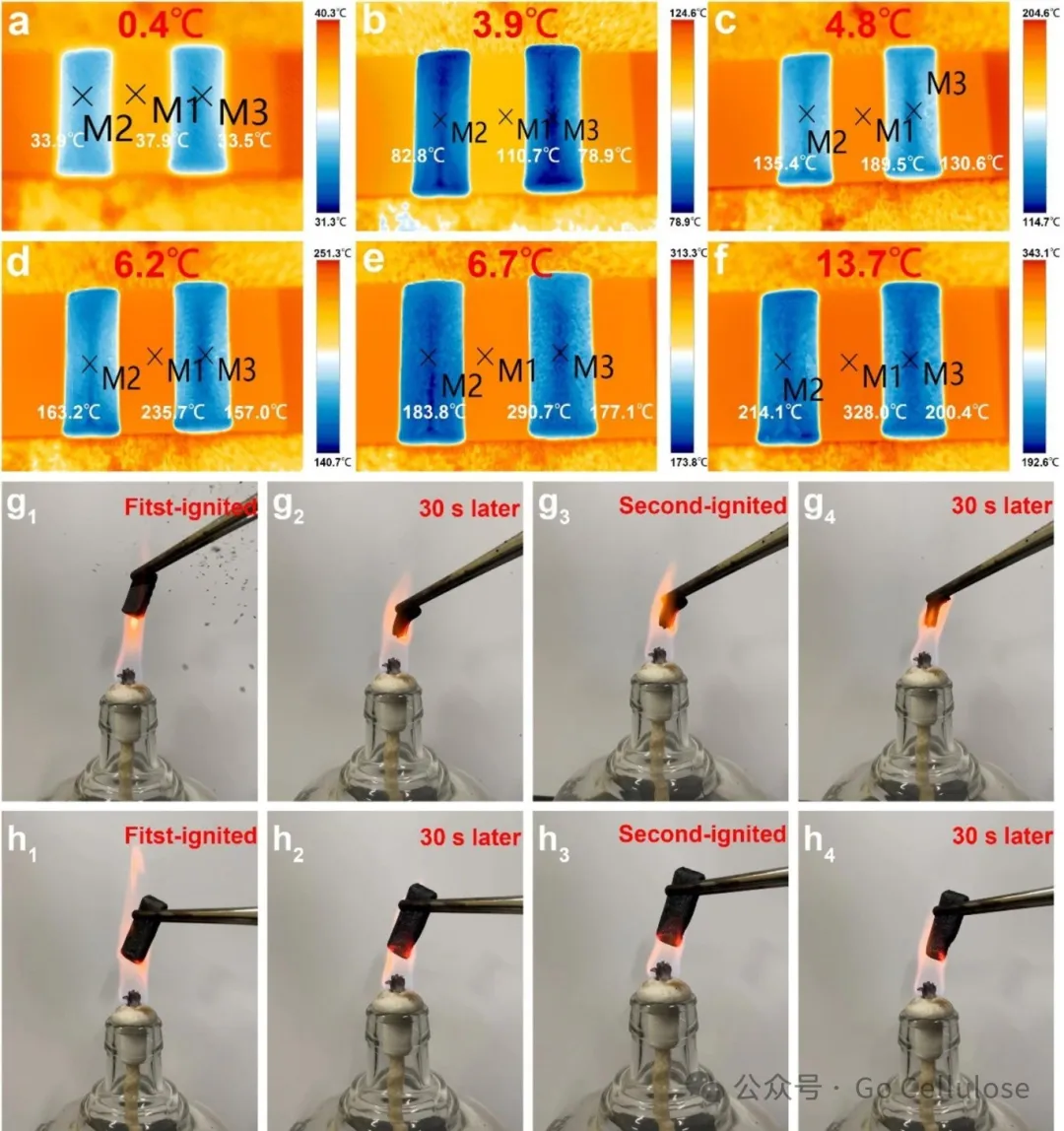

Figure 5: Fire warning test process. - Thermal Insulation and Flame Retardant Properties Figure 6 investigates the thermal insulation performance of GO-based aerogels. The results show that GA-CNF-20 demonstrates excellent thermal insulation, maintaining a surface temperature lower than GA-CNF-0 and retaining its insulation properties under high temperatures. The lower thermal conductivity of GA-CNF-20 supports its superior insulation, which is attributed to the low density and high porosity of the GO-based aerogel and the stabilizing effect of CNF on its structure.

Figure 6: Infrared thermal images and combustion tests.

Figure 6: Infrared thermal images and combustion tests.

Conclusion This work introduces a straightforward and effective strategy for fabricating ultra-sensitive fire warning sensors using 3D printing. Specifically, due to multiple hydrogen bonding interactions and a robust gel network structure, the ink containing 20 wt% CNF (GA-CNF-20) demonstrated ideal viscosity (~11,400 Pa·s), high storage modulus (~10,800 Pa), significant shear-thinning behavior, and a dynamic yield stress of 620 Pa. The printed product exhibits excellent shape fidelity and self-supporting capability. After freeze-drying, the GA-CNF-20 aerogel’s elastic modulus significantly increased to 153 kPa, deforming up to 39.7% under 400 kPa compressive stress. GA-CNF-20’s fire warning trigger time is 1.32 s, with a prolonged response time of 170 s. This is due to the APP-based IFR system’s ability to catalyze the formation of a solid crosslinked conductive phosphorized carbon layer at high temperatures, ensuring timely, continuous fire warning signals during flame exposure. GA-CNF-20 also displays strong thermal insulation and self-extinguishing properties during combustion. The customizable crosslinked structure achieved via DIW 3D printing and freeze-drying imparts the aerogel with favorable geometric characteristics, excellent fireproofing and thermal properties, and notable mechanical strength. This paves the way for highly sensitive fire protection sensors with promising applications in buildings requiring advanced fire alarm and prevention systems.

Innovation This study leveraged DIW 3D printing technology, utilizing CNF as a toughening agent and APP to construct an IFR system, resulting in GO-based aerogels with excellent fire warning and flame-retardant properties. The integration of APP created an intumescent flame retardant system that allows GO-based aerogels to form a dense, conductive phosphorized carbon layer under fire conditions, facilitating continuous fire warning signals. These aerogels offer controllable 3D structures, high shape stability, mechanical strength, fire warning capabilities, and flame-retardant properties, providing a novel solution for fire safety.

Implications DIW 3D printing technology can be combined with various materials to create smart materials with excellent performance and controllable structures. The introduction of functional fillers can further enhance material properties, broadening potential applications. This study also presents new ideas and methods for developing innovative fire warning and flame-retardant materials.