Carbon Nanotube Modified Asphalt Technology for Enhanced Crack Resistance and Durability

Introduction

Asphalt, a fundamental component in road construction, is continuously exposed to various environmental and mechanical stresses, such as temperature fluctuations, heavy traffic loads, and weathering. These stresses often result in cracking, rutting, and other forms of damage, leading to frequent repairs and maintenance costs. To improve the performance and longevity of asphalt pavements, researchers have been exploring the incorporation of advanced materials, particularly carbon nanotubes (CNTs), as modifiers for asphalt.

Carbon nanotubes, with their remarkable mechanical, thermal, and electrical properties, offer significant potential to enhance the crack resistance and durability of asphalt mixtures. This article explores the role of CNTs in modifying asphalt, the mechanisms by which they improve its properties, and the challenges and future directions of this technology.

What Are Carbon Nanotubes?

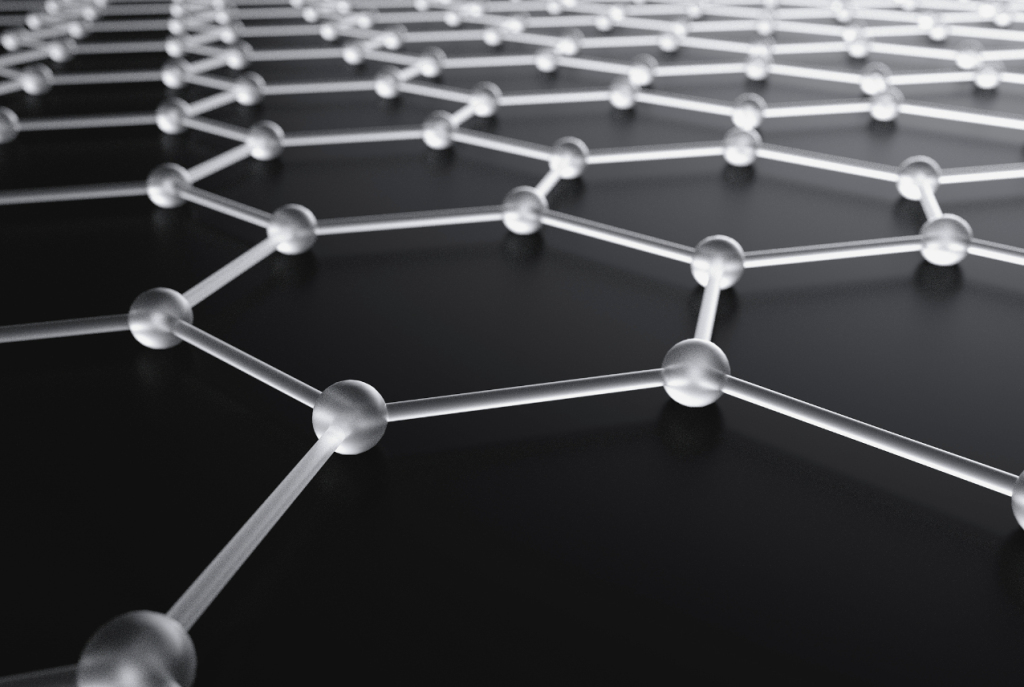

Carbon nanotubes (CNTs) are cylindrical nanostructures composed of carbon atoms arranged in a hexagonal pattern. CNTs come in two primary types:

- Single-walled carbon nanotubes (SWCNTs): Comprising a single graphene layer rolled into a tube.

- Multi-walled carbon nanotubes (MWCNTs): Consisting of multiple concentric layers of graphene.

CNTs are celebrated for their:

- Exceptional mechanical strength: They are one of the strongest materials known, with tensile strengths many times higher than steel.

- High thermal conductivity: CNTs efficiently transfer heat, which can help in managing the temperature of asphalt surfaces.

- High surface area: The large surface area of CNTs allows them to form strong interactions with the binder components in asphalt.

- Excellent electrical conductivity: While not a primary property for asphalt, this can help with sensing applications in smart pavements.

Given these properties, CNTs can significantly improve the mechanical properties of asphalt, making it more resistant to cracking and more durable over time.

Mechanisms of CNT Modification in Asphalt

When CNTs are added to asphalt, they improve its properties through several mechanisms:

-

Enhanced Binding Properties:

- The high surface area of CNTs allows them to interact more effectively with the asphalt binder (bitumen), leading to a stronger bond between the aggregates and the binder. This improves the cohesion of the asphalt mixture and reduces the likelihood of aggregate loss or binder stripping.

- CNTs can act as nano-fillers, reinforcing the matrix and improving the overall structural integrity of the asphalt.

-

Improved Mechanical Properties:

- The mechanical strength of CNTs is one of the primary reasons for their effectiveness in asphalt modification. By integrating CNTs, the asphalt mixture gains higher tensile strength, flexural strength, and compressive strength. This results in better resistance to cracking and deformation under stress, making the asphalt more durable and able to withstand heavy traffic loads.

- CNTs help in enhancing elasticity, which allows the asphalt to deform without cracking, reducing the risk of thermal cracking and fatigue cracking.

-

Crack Resistance:

- Asphalt pavements often develop cracks due to repetitive stress, thermal fluctuations, or aging. CNTs act as reinforcing agents, preventing the propagation of cracks by distributing the stress more evenly across the asphalt matrix.

- By reinforcing the binder, CNTs reduce fracture toughness and increase the toughness of the material, making it less likely to fail under stress.

-

Increased Durability:

- CNTs also contribute to the weathering resistance of asphalt. As the material is exposed to ultraviolet light, oxidation, and moisture, the performance of conventional asphalt may degrade. CNTs, due to their high stability and resistance to environmental factors, can help maintain the integrity of the asphalt for a longer time.

- Additionally, CNTs may enhance the oxidative stability of asphalt, delaying the oxidation process and extending the lifespan of the material. This means that asphalt modified with CNTs will be more resistant to aging, reducing the frequency of repairs.

-

Improved Rheological Properties:

- CNTs improve the rheological properties of asphalt binders, making them more resistant to temperature-induced softening or hardening. This is particularly important in regions with extreme temperatures, where asphalt can soften in hot weather and become brittle in cold conditions. CNT-modified asphalt remains more stable across a broader range of temperatures.

Types of CNT Modified Asphalt

CNTs can be incorporated into asphalt through various methods, depending on the desired properties and performance characteristics. The most common methods of incorporating CNTs into asphalt include:

-

Direct Mixing:

- CNTs are mixed directly with the asphalt binder during the asphalt production process. The CNTs are either dispersed into the asphalt binder through high-shear mixing or ultrasonic dispersion methods.

- This method can be effective in achieving a uniform distribution of CNTs within the binder, but careful control of dispersion is required to ensure that the CNTs are well-integrated into the mixture.

-

Hybrid Modification:

- CNTs can also be combined with other additives, such as polymer modifiers, nano-silica, or rubber, to enhance the performance of asphalt further. This hybrid approach may provide a broader range of improvements, such as increased elasticity and improved aging resistance.

-

Functionalized CNTs:

- Functionalizing CNTs with various chemical groups can improve their interaction with the asphalt binder. This can enhance the dispersion of CNTs in the mixture and lead to better compatibility with the asphalt. Functionalized CNTs can form stronger bonds with the asphalt components, resulting in better mechanical performance.

Benefits of CNT-Modified Asphalt

The incorporation of CNTs into asphalt mixtures offers several significant advantages:

-

Improved Crack Resistance:

- CNT-modified asphalt is less prone to cracking under stress. The nanotubes act as reinforcement, preventing the propagation of cracks and reducing the overall fatigue cracking of the pavement.

-

Increased Durability and Longevity:

- Asphalt modified with CNTs exhibits better resistance to thermal, environmental, and mechanical degradation. This translates to longer-lasting pavements that require fewer repairs and replacements, reducing lifecycle costs.

-

Enhanced Performance in Extreme Temperatures:

- In regions with extreme temperatures, CNT-modified asphalt performs better than conventional asphalt, remaining stable in both hot and cold conditions.

-

Improved Performance Under Heavy Traffic:

- CNTs reinforce the asphalt matrix, making it more resistant to deformation and rutting caused by heavy traffic loads. This is especially important in urban areas and highways subjected to constant traffic stress.

-

Environmental Benefits:

- By improving the durability of asphalt, CNTs can contribute to reducing the frequency of asphalt repairs, which in turn reduces the consumption of raw materials and energy for maintenance. This contributes to more sustainable road construction practices.

Challenges and Considerations

Despite the potential benefits, the use of CNTs in asphalt modification presents certain challenges:

-

Dispersion Issues:

- One of the main challenges in using CNTs in asphalt is achieving a uniform dispersion of CNTs within the binder. Poor dispersion can lead to inconsistent performance and reduced effectiveness. Specialized mixing techniques and surfactants may be required to overcome this issue.

-

Cost:

- CNTs are still relatively expensive compared to traditional asphalt additives, which may limit their widespread use, particularly in low-cost or large-scale applications. However, as production methods for CNTs improve and costs decrease, their use in asphalt may become more economically viable.

-

Durability and Long-Term Performance:

- While CNTs improve the initial performance of asphalt, their long-term performance, particularly in terms of resistance to environmental degradation, needs further research and testing. Over time, the interaction between CNTs and the binder may degrade, potentially impacting the overall performance of the asphalt.

Future Directions

Future research into CNT-modified asphalt is focused on:

- Improved CNT dispersion techniques: Developing new methods to achieve more consistent and uniform distribution of CNTs in asphalt.

- Cost reduction: Advancements in CNT production processes to make them more cost-effective for large-scale use in road construction.

- Long-term durability studies: More comprehensive testing of CNT-modified asphalt under real-world conditions to assess its long-term performance and aging resistance.

- Hybrid approaches: Combining CNTs with other advanced additives to further enhance the performance of asphalt.

Conclusion

Carbon nanotubes represent a promising technology for improving the crack resistance and durability of asphalt. Their remarkable mechanical properties, including high strength, elasticity, and thermal stability, make them ideal candidates for modifying asphalt mixtures to withstand harsh environmental conditions, heavy traffic, and aging. While challenges such as dispersion issues and cost remain, ongoing research and advancements in CNT production methods are likely to overcome these barriers and enable the broader adoption of CNT-modified asphalt for more sustainable, durable, and high-performance road construction.