Major Breakthrough in the Preparation of Ultra-Long Carbon Nanotubes by Tsinghua University!

Recently, Associate Professor Zhang Rufan’s research team from the Department of Chemical Engineering at Tsinghua University reported a new method for controllably preparing ultra-long carbon nanotubes using floating bimetallic catalysts, achieving significant improvements in the yield and uniformity of 30 cm-long carbon nanotube horizontal arrays.

Key Points

Demand for Carbon Nanotubes: Carbon nanotubes (CNTs) are one-dimensional nanomaterials with excellent thermal, mechanical, and electromagnetic properties, making them highly sought after in fields such as carbon-based integrated circuits, super-strong and tough fibers, transparent conductive films, and flexible wearable devices. High-end applications demand stringent requirements for CNTs in terms of length, orientation, defect levels, and purity.

Challenges in Growing Ultra-Long CNTs: Ultra-long CNTs, which follow a tip-growth mode, are essential for meeting these requirements and realizing the intrinsic superior properties of CNTs. However, the growth process involves the self-assembly of tens of billions of atoms under stringent conditions, leading to low yield and array density typically less than 50 tubes per mm, limiting application development.

3.

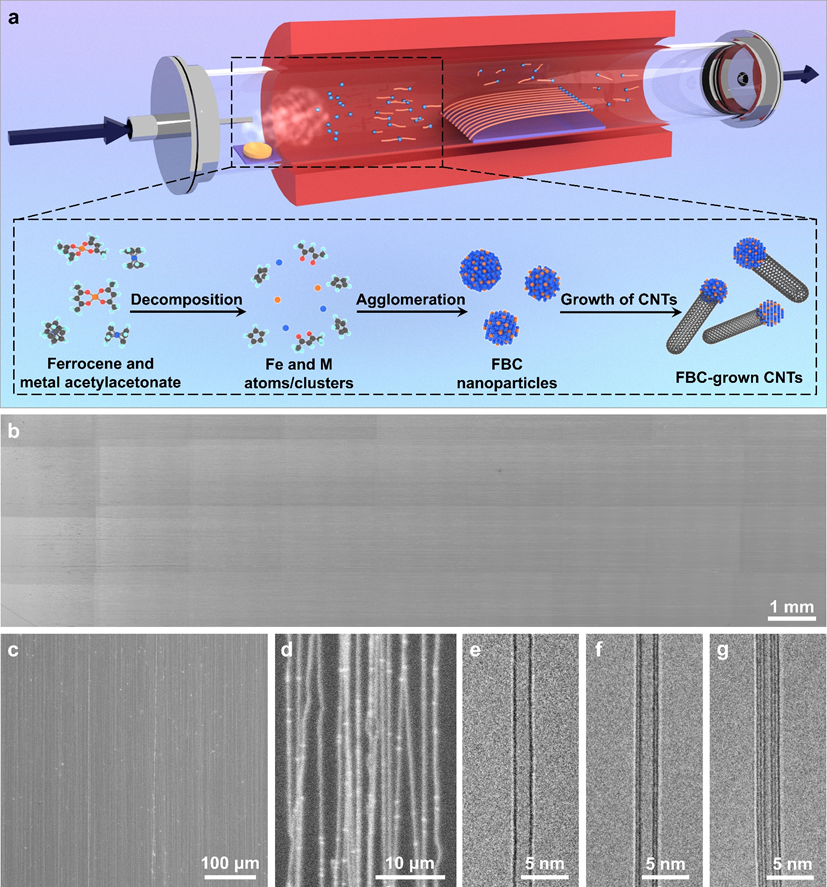

New Method with Floating Bimetallic Catalysts (FBCs): Building on their previous strategy of substrate interception guidance, Zhang’s team proposed an in-situ gas-phase synthesis method using FBCs (Figure 1). They introduced ferrocene and acetylacetonate salts (as iron and secondary metal precursors) into the reactor. The diverse and easily sublimable nature of acetylacetonate salts facilitates the formation of new binary alloy floating catalysts.

4.

Process Description: The precursors undergo sublimation, decomposition, and coalescence at the reactor inlet to form FBC nanoparticles, which are continuously introduced into the reactor with carrier gas. The carbon source decomposes on the FBC particles, growing CNTs floating in the gas phase. Substrate edges in the reactor intercept these floating CNTs, guiding their growth and significantly increasing the probability of “kite” mode growth. FeCu catalysts grown CNT horizontal arrays showed markedly improved yield, density, and uniformity compared to Fe catalysts.

Figure 1: High yield and uniform preparation of ultra-long carbon nanotube horizontal arrays using floating bimetallic catalysts

5.

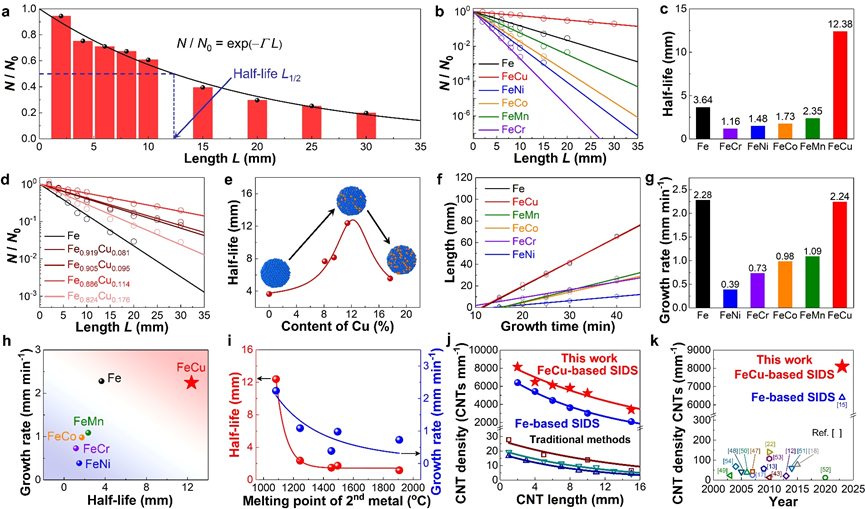

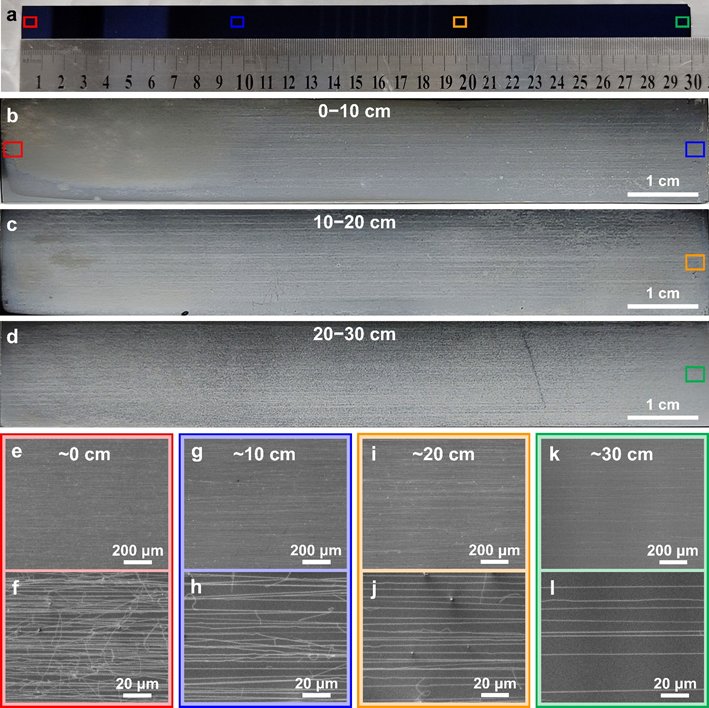

Optimization of FBCs: The team further studied the lifespan and activity patterns of FBC-type catalysts (Figure 2). They used the half-life of array density as a descriptor for catalyst lifespan and the growth rate of arrays as a descriptor for catalyst activity, deriving the related phase diagram (Figure 2h). FeCu catalysts with 11.4% Cu content had the longest half-life (12.38 mm), 3.40 times that of Fe catalysts, and a growth rate close to Fe catalysts (2.24 mm/min), key for significantly improving the yield and uniformity of ultra-long CNT arrays. The optimized conditions produced 30 cm high-density CNT horizontal arrays with large-area uniformity (Figure 3). The highest density reached 8100 tubes/mm, with minimal density attenuation along the length. At 30 cm, the CNT density remained 90 tubes/mm, significantly better than previous reports.

6.

Figure 2: Screening and optimization of floating bimetallic catalysts

7.

Figure 3: Controllable preparation of 30 cm-long carbon nanotube horizontal arrays

Research Outcome

The study, titled “Floating Bimetallic Catalysts for Growing 30 cm-Long Carbon Nanotube Arrays with High Yields and Uniformity,” was published in Advanced Materials. The first author is Jiang Qinyuan, a direct PhD student from the 2019 cohort, and the corresponding author is Associate Professor Zhang Rufan. The research was supported by the National Natural Science Foundation of China and the National Key Research and Development Program.

Original Article Link: Advanced Materials

Source: Carbontech