Midea: New Graphene Technology Extends Air Conditioner Lifespan Significantly

On September 1st, Midea Group’s 2024 semi-annual report revealed a breakthrough project: the “Key Technology and Application of Graphene-Modified Anti-Corrosion Coating for Air Conditioner Heat Exchangers.” This innovation, based on an original lifespan evaluation model and a new coating evaluation method for aluminum foil, has led to the development of a high-performance graphene-modified coating. This coating not only improves corrosion resistance and heat conductivity but also enhances resistance to UV aging, ensuring long-term energy efficiency. The technology has been certified by Intertek’s accelerated testing, simulating over 20 years of use in a saline industrial environment, and is now being applied to several high-end products, helping Midea penetrate the premium market.

Air conditioners control temperature primarily by transferring heat, with the heat exchanger fins being the main component for dissipating heat. However, corrosion of these fins significantly reduces heat transfer efficiency, especially in coastal and island regions, where sunlight and humidity accelerate degradation. One conventional solution is to thicken the coating on the fins, but this often compromises heat conductivity, leading to higher energy consumption.

A long-standing issue in the air conditioning industry has been the decline in performance over extended use, with one of the major culprits being the weather resistance of heat exchanger fins. Midea’s air conditioning team has harnessed the anti-corrosion, high thermal conductivity, and antibacterial properties of high-quality thin-layer graphene to address this issue. This breakthrough was featured in the May issue of Nature in an article titled “Making Leaps Towards Sustainable Air Conditioning.” The article highlights the innovative features of Midea’s “Graphene Ultra-Thin Coating Technology,” which improves the durability, anti-aging properties, and corrosion resistance of heat exchanger fins, resulting in more efficient heat transfer.

The heat exchanger is a critical component of the air conditioning system, responsible not only for heat transfer and temperature regulation but also for ensuring the unit operates efficiently and stably. However, the operating environment is often harsh, with challenges such as corrosion and aging due to pollutants like CO2, sulfur compounds, nitrogen oxides, vehicle exhaust, as well as extreme weather conditions like heat, humidity, and salt fog. Even UV radiation contributes to the deterioration of heat exchangers. According to COLMO’s research, even without direct exposure to sunlight, heat exchanger fins can experience approximately 1/6 of the damage caused by light-induced corrosion.

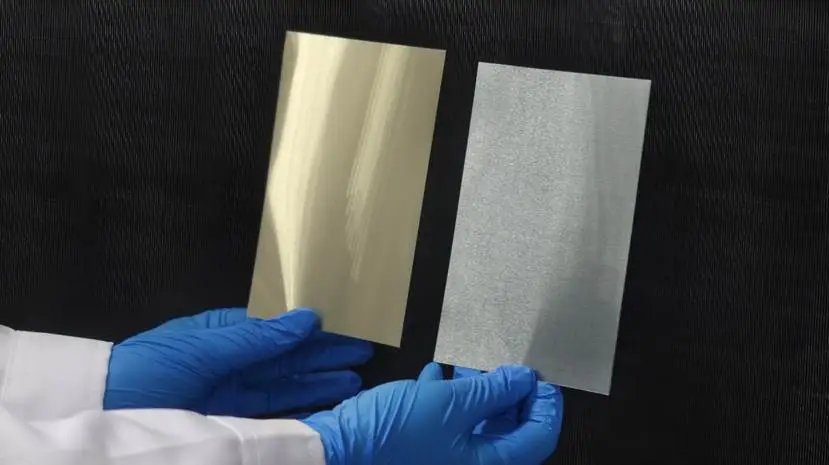

After identifying that the coating failures were due to a combination of sunlight, corrosive agents, and moisture, Midea’s research team developed a new aluminum foil evaluation method based on the failure mechanisms and lifespan assessment model. By designing new coatings and adding graphene, they achieved a breakthrough in both corrosion resistance and heat conductivity. The thermal diffusivity increased by 31%, and post-aging corrosion resistance improved fivefold.

The graphene-coated “Black Gold Fins” can withstand severe acid corrosion for 20 to 50 years. In experiments, after 240 hours of direct UV exposure and 72 hours in a neutral salt spray environment, less than 0.02% of the surface showed corrosion—far superior to traditional materials.

Moreover, graphene coatings offer high thermal conductivity and hydrophilicity, enabling more efficient heat exchange. Compared to traditional air conditioner fins, COLMO’s graphene-coated Black Gold Fins saw a 31% improvement in thermal conductivity and a 92.5% increase in hydrophilicity, allowing the unit to run more efficiently and save energy. This technology not only extends the lifespan of air conditioners but also reduces carbon emissions during operation and mitigates resource waste and environmental pollution caused by metal corrosion. This breakthrough will undoubtedly propel the air conditioning industry toward healthier, more sustainable, and lower-carbon solutions.

Indoors, the graphene Black Gold Fins demonstrate strong self-cleaning abilities. Their high hydrophilicity allows impurities on the evaporator to be flushed away with condensation, reducing bacteria and mold growth and keeping indoor air fresh. The research, validated through Intertek’s accelerated testing, indicates a lifespan of over 20 years in harsh environments, significantly extending the operational life of air conditioners.