Advances in Graphene Electrodes for Triboelectric Nanogenerators

Overview

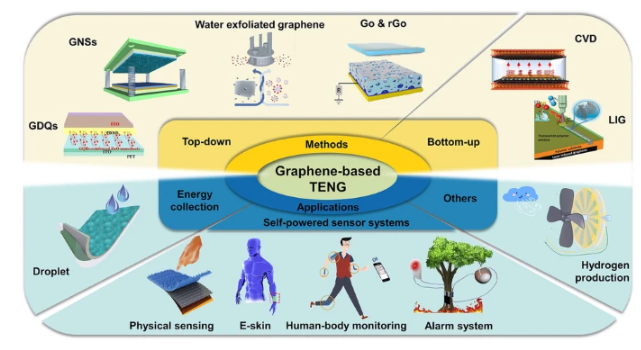

With the rapid development of wearable electronics, wireless sensor networks, and micro-devices, the demand for compact, flexible, and efficient energy harvesting technologies is rising. Triboelectric nanogenerators (TENG) offer a promising solution by converting mechanical energy into electrical energy. However, the choice of electrode material significantly affects the performance of TENGs. Traditional metal electrodes face durability issues, limiting their application.

Graphene, with its exceptional electrical properties and mechanical strength, emerges as a promising alternative. A recent review from Professor Yun Chen’s team at Guangdong University of Technology was published in Nano-Micro Letters under the title “Advances in Graphene-Based Electrode for Triboelectric Nanogenerator”. The paper systematically summarizes graphene electrode processing techniques and explores various applications and performance enhancements in TENGs. It also discusses future trends in graphene-electrode-based TENG technology.

Precision Processing of Graphene Electrodes

Due to the increasing demand for advanced TENG devices, efficient and precise graphene electrode manufacturing is essential. There are two main approaches to graphene electrode fabrication:

- Top-down methods: This involves breaking down bulk materials into graphene sheets.

- Bottom-up methods: Techniques like chemical vapor deposition (CVD) build graphene from carbon-based precursors.

These methods enable high-quality graphene electrodes, improving conductivity, durability, and flexibility.

Applications of Graphene Electrodes in TENGs

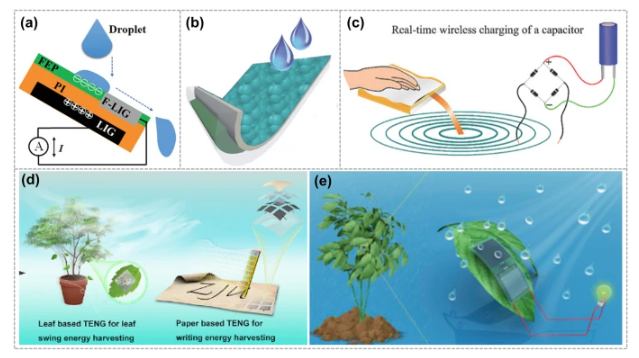

- Energy Harvesting:

Graphene-based TENGs are widely used for harvesting mechanical energy from the environment. These systems can power small electronic devices through ambient motion.

-

(Figure 1): Energy harvesting application of graphene-electrode TENGs.

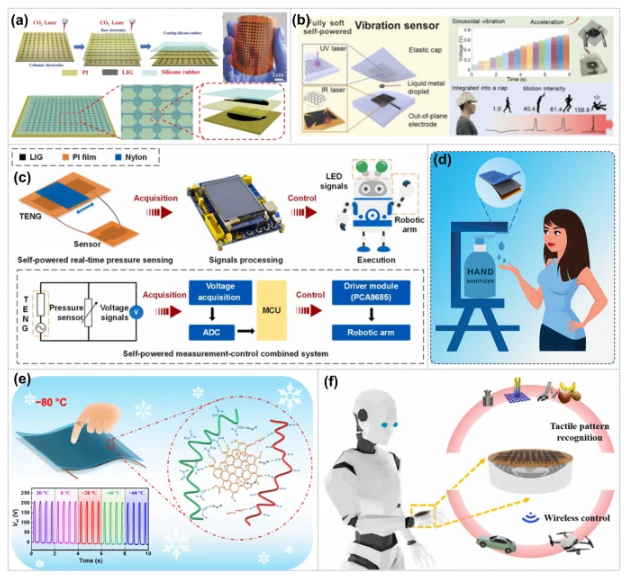

- Self-Powered Sensors:

These sensors utilize graphene’s superior conductivity and mechanical properties for enhanced detection performance. Integrating TENGs with other technologies creates smart systems for wireless control and real-time monitoring.

(Figure 2): Use of graphene-electrode TENGs in physical sensors and IoT devices.

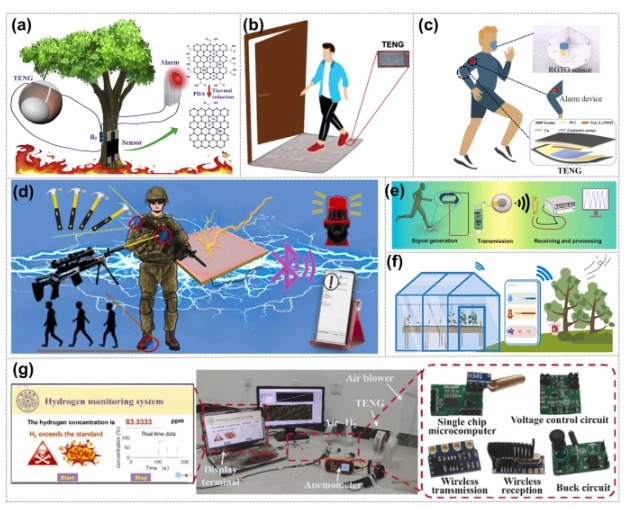

- Alarm Systems:

Graphene-based TENGs can be integrated into security systems for self-powered alarms, ensuring reliable performance even under harsh conditions.

(Figure 3): Graphene-electrode TENGs in alarm systems.

Summary and Future Outlook

Graphene electrodes have become essential for advancing TENGs, especially in wearable electronics and renewable energy solutions. The material’s superior conductivity, flexibility, and transparency contribute to developing responsive e-skin for human motion monitoring, water purification systems, and hydrogen production.

Future research will focus on several areas:

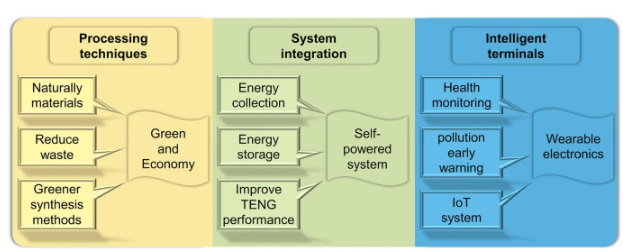

- Processing Technologies:

Top-down methods, such as polymer composites (e.g., PDMS, PVDF), enhance TENG performance but pose challenges due to complex synthesis and waste generation. Environmentally sustainable manufacturing methods are critical for future developments. - System Integration:

TENGs can convert environmental energy into electrical power with peak power densities of hundreds of watts per square meter. Integrating TENGs with supercapacitors allows simultaneous energy harvesting and storage, paving the way for self-powered systems. - Smart Terminals:

Graphene-based TENGs have proven potential in human health monitoring, wastewater purification, hydrogen generation, and sterilization. Integrating TENGs with IoT technologies will lead to smart terminal systems for real-time monitoring of health and environmental parameters.

Challenges and Future Directions

- Material Innovation: Developing eco-friendly graphene electrodes using natural materials (e.g., cork, fruit shells) can enhance sustainability. Laser-induced graphene (LIG) techniques also require optimization to reduce material defects.

- Surface Functionalization: Tailoring graphene surfaces with functional groups enhances contact area and system stability, increasing energy-harvesting efficiency.

- System Longevity: Improving the robustness and lifespan of graphene-based TENG systems is essential for practical applications.

As graphene processing technologies evolve, research will likely explore alternative 2D materials like MXenes to further enhance TENG performance. Addressing these challenges will lead to sustainable, high-performance energy solutions and open new avenues for self-powered wearables.

Reference:

https://doi.org/10.1007/s40820-024-01530-1