New Pathways for Graphene Applications!

Since its discovery, graphene has been highly anticipated for its outstanding physical properties, demonstrating extensive application potential across various fields. The Chemical Vapor Deposition (CVD) method is particularly attractive for large-scale graphene production due to its high controllability and scalability. However, existing graphene CVD technologies primarily focus on metallic substrates (such as copper and nickel), which facilitate the growth of high-quality graphene due to their catalytic activity. The growth of graphene on non-metallic, non-catalytic substrates (like glass and sapphire) faces numerous challenges, especially in achieving high uniformity and defect-free graphene deposition on large-scale, three-dimensional complex structures (like glass fiber fabric, GFF). This has been one of the bottlenecks limiting graphene applications.

The traditional graphene preparation process requires transferring graphene from the catalytic substrate to the target substrate, a transfer that often results in contamination, damage, and folding of the graphene layers, severely restricting its applications. Growing graphene directly on the target substrate, particularly on non-catalytic, complex structures, can bypass these issues, representing a significant step forward in the transformation of graphene technology.

Hydrodynamic Rectification Strategy

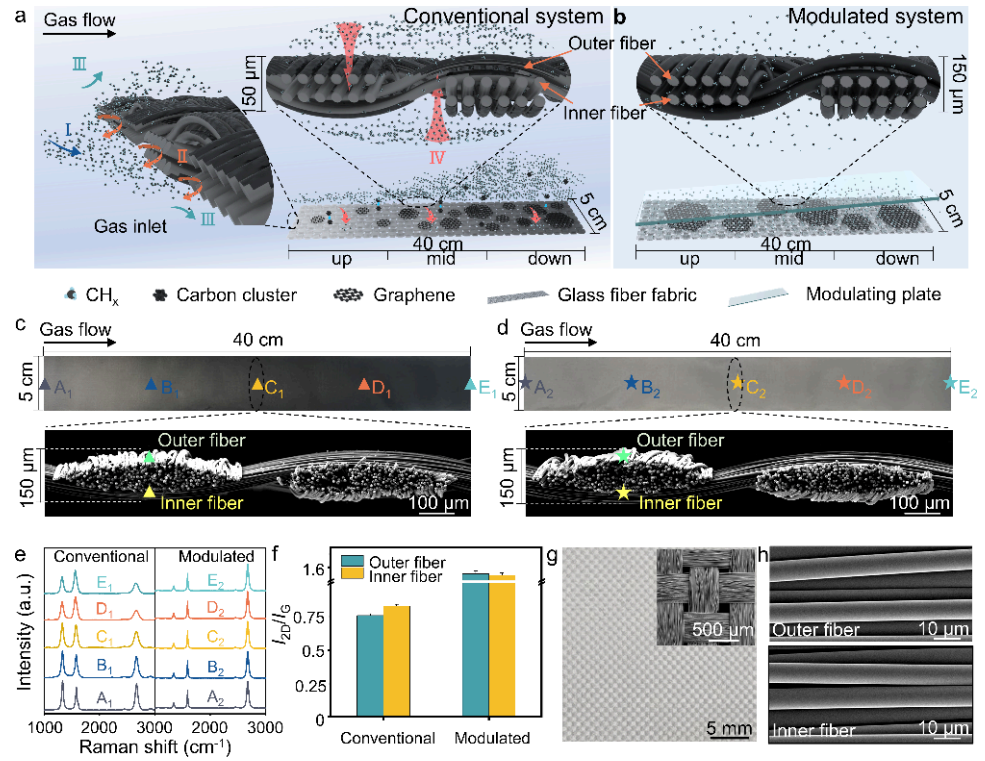

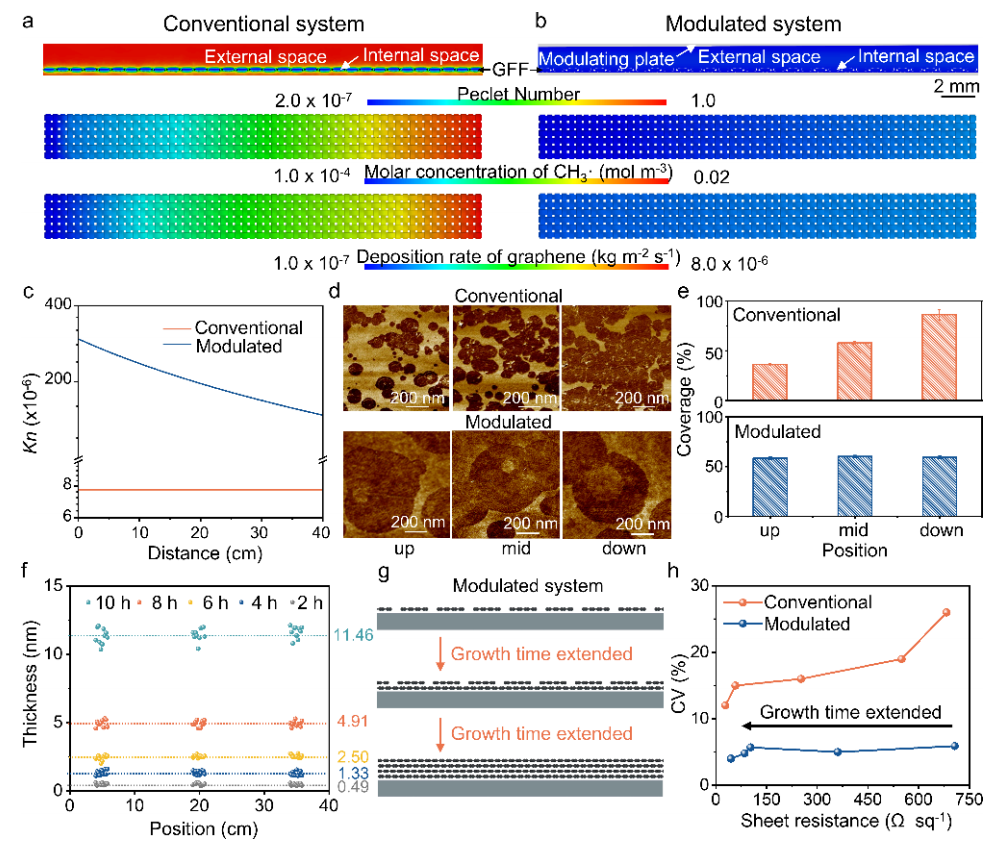

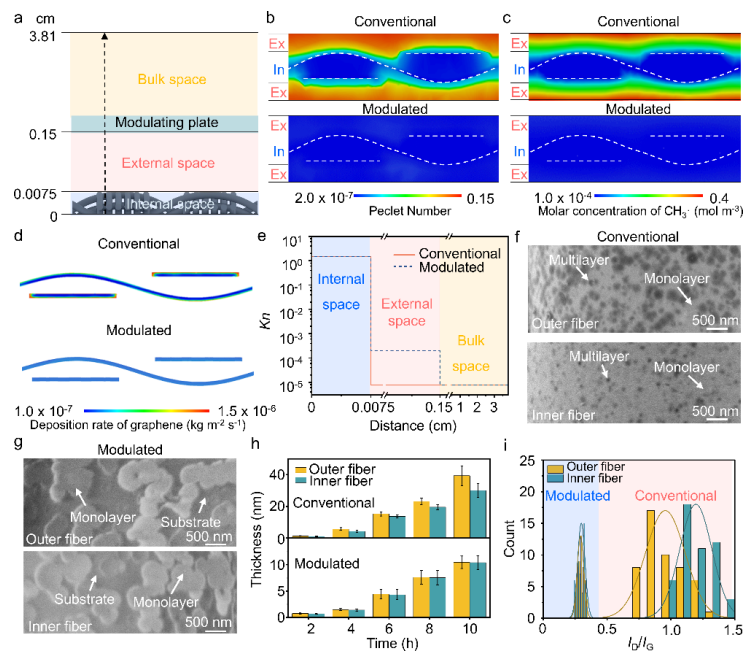

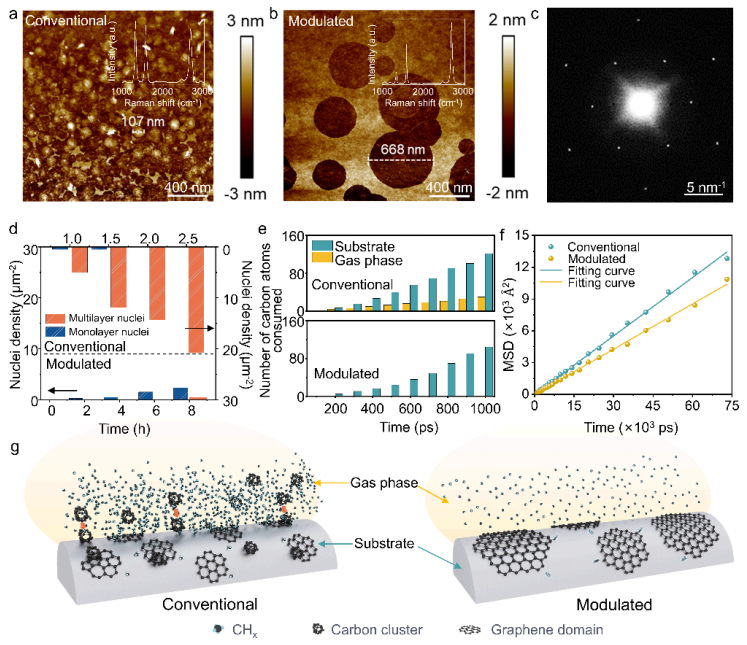

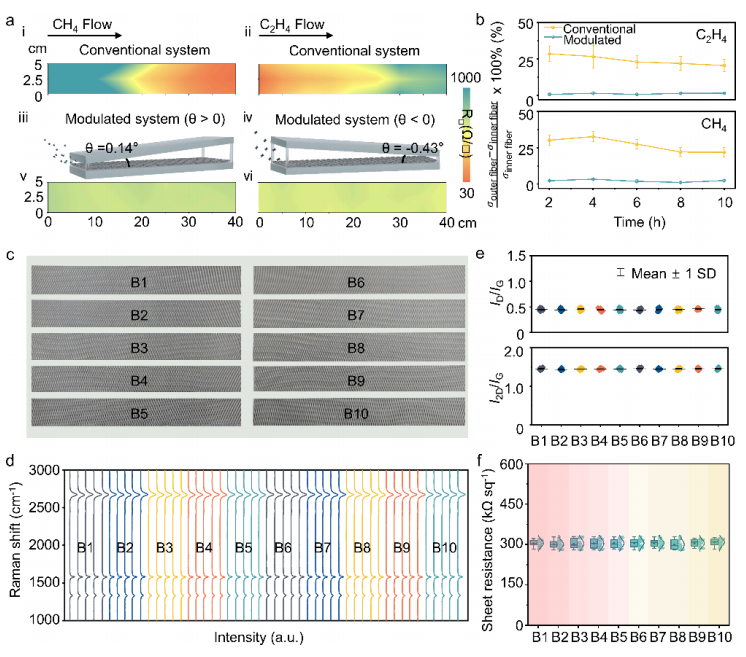

To address these challenges, a team led by Academician Liu Zhongfan from Peking University proposed a hydrodynamic rectification strategy to achieve high uniformity and quality of graphene deposition on the three-dimensional structure of glass fiber fabric (GFF). They developed graphene-skinned glass fiber fabric (GGFF). The key to this strategy lies in controlling the distribution of carbon source materials and their collision frequency with the substrate through adjusting the hydrodynamic behavior of gas-phase reactions in the CVD system, thus enabling uniform graphene growth on the fiber surfaces. Specifically, researchers designed a tapered space to optimize gas flow and carbon source distribution while reducing the formation of by-products, thereby enhancing graphene quality. This is the first hydrodynamic rectification strategy proposed to synergistically adjust the distribution of carbon species in three-dimensional space and their interactions with structured substrates, resulting in highly uniform deposition of high-quality graphene on the fibers of large-scale 3D woven fabrics.

This rectification strategy is highly versatile and scalable, applicable to various carbon precursor materials (such as methane and ethylene), enabling the mass production of uniformly coated graphene fiber fabrics.

Performance of GGFF

Using the above hydrodynamic rectification strategy, researchers successfully produced GGFF and showcased its potential in natural energy harvesting. This new material offers several significant performance advantages:

- High Electrical Conductivity: GGFF exhibits excellent conductivity suitable for various energy-related applications.

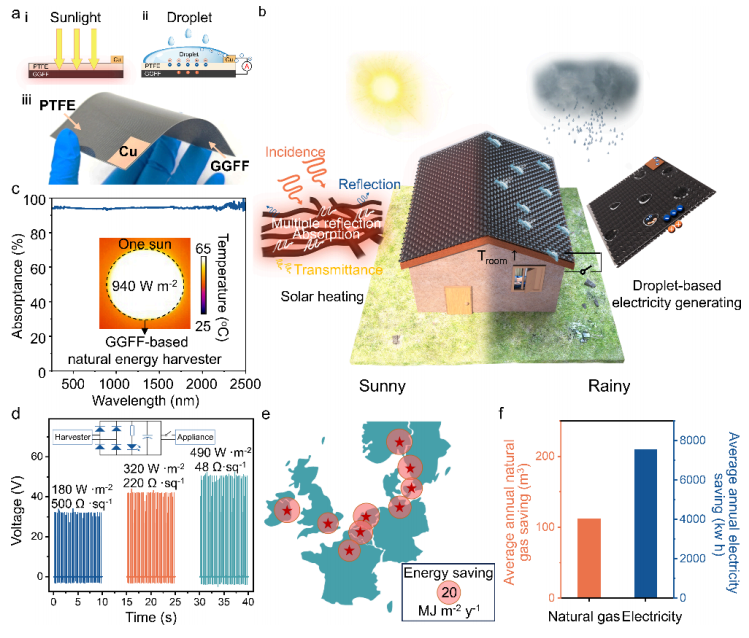

- High Photothermal Conversion Efficiency: GGFF has an impressive solar absorption rate (around 0.92), efficiently converting solar energy into thermal energy.

- Multifunctional Energy Harvester: Leveraging the photothermal conversion capability and superior conductivity of GGFF, researchers developed a natural energy collector capable of simultaneously harvesting solar and raindrop energy.

Applications of the Natural Energy Collector

The natural energy collector proposed in this study integrates photothermal conversion and raindrop electricity generation functionalities, enabling operation under different climatic conditions.

- Sunny Days: GGFF absorbs sunlight and, through its photothermal conversion characteristics, transforms solar energy into heat, which can be utilized for heating buildings and other applications.

- Rainy Days: The collector generates charges through the friction of raindrops against a hydrophobic PTFE surface, converting kinetic energy into electrical energy via charge induction and electrostatic induction. GGFF serves as the lower electrode to collect charges, forming a circuit that completes energy collection and stores it in an external capacitor.

This natural energy collector has potential applications as a roofing material for buildings, providing sustainable energy solutions by utilizing solar heating on sunny days and generating electricity from raindrop energy on rainy days. Simulation results indicate that GGFF-based energy collectors can achieve an annual average energy savings of about 20 MJ/m² in coastal cities in Europe, translating to significant savings in electrical energy and natural gas, demonstrating excellent energy management potential.

Furthermore, this strategy shows exceptional versatility and scalability. Research indicates that the hydrodynamic rectification strategy is applicable to various types of carbon precursor materials (like methane and ethylene) and can be used with other substrate materials, such as alumina fiber fabrics and quartz plates, forming diverse graphene composites. The strategy ensures uniform graphene deposition while maintaining product stability across multiple production batches.

Conclusion and Outlook

This study demonstrates the feasibility of successfully preparing high-quality graphene composite materials on complex three-dimensional structures through a hydrodynamic rectification strategy. This approach overcomes many challenges associated with traditional CVD graphene growth, opening up new possibilities for graphene applications in energy, electronics, construction, and more. Future prospects for this technology include expanding to more substrate types and application scenarios, such as aerospace and wearable devices. In summary, this significant breakthrough combines the exceptional properties of graphene with the mechanical advantages of engineering materials, paving the way for new applications in high-performance composite materials.

For related research findings, see “Fluid-Dynamics-Rectified Chemical Vapor Deposition (CVD) Preparing Graphene-Skinned Glass Fiber Fabric and Its Application in Natural Energy Harvest” published in JACS on August 30.

Images:

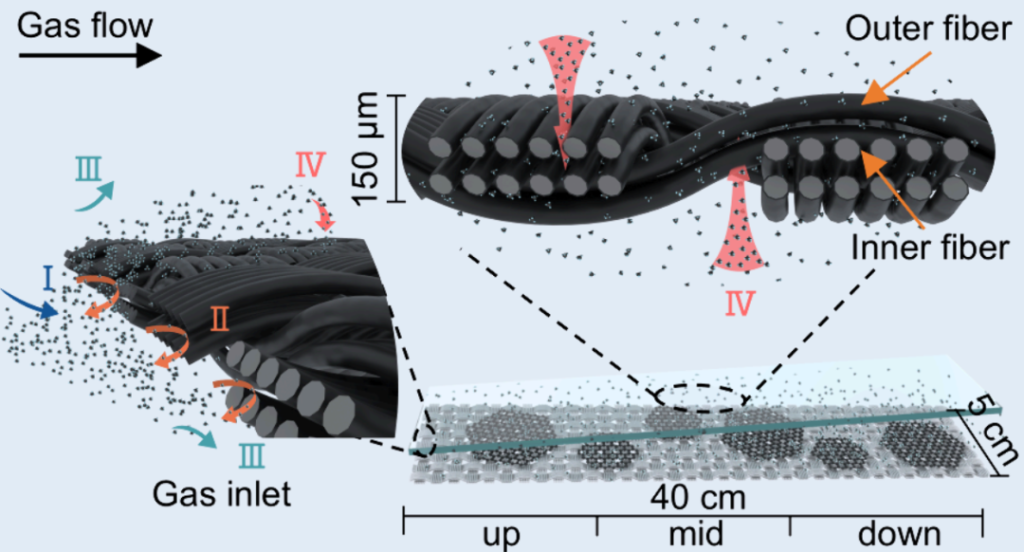

- Manufacturing processes of GGFF with and without hydrodynamic rectification strategy.

- Hydrodynamic simulation and CVD growth of graphene on GFF along the gas-phase deposition system.

- Hydrodynamic simulation and CVD growth of graphene on GFF in a direction perpendicular to GFF.

- The impact of hydrodynamic rectification on graphene growth quality.

- The universality and scalability of the hydrodynamic rectification strategy.

- Natural energy collector based on GGFF, featuring solar heating and raindrop power generation capabilities.