Magical Graphitic Carbon Nitride/Loofah/Chitosan Hydrogel Solar Evaporator: A Powerful Tool for Seawater Desalination and Antibiotic Degradation

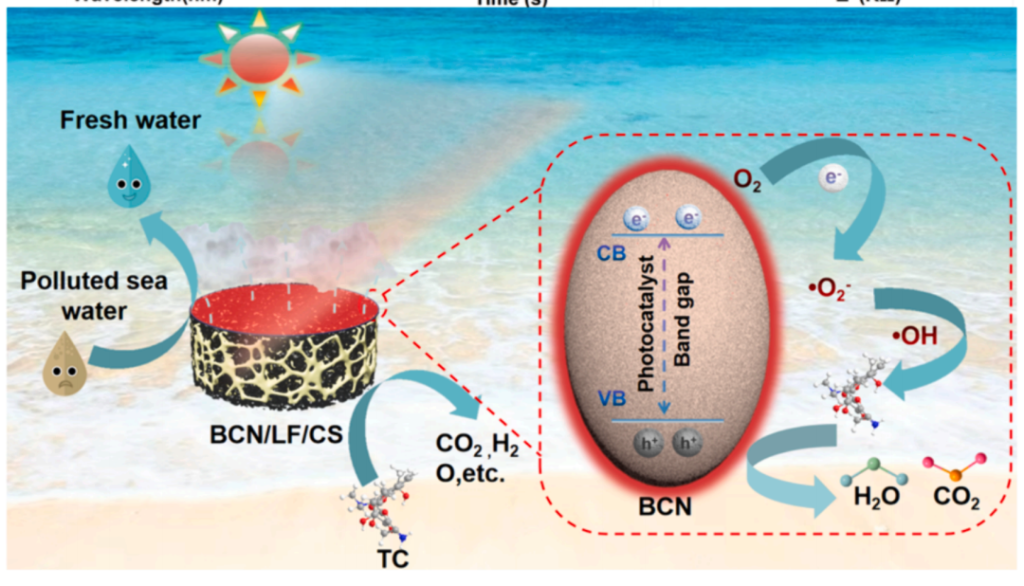

Researchers from Jiangsu University of Science and Technology (School of Materials Science and Engineering), including Weilong Shi from the School of Energy and Power, and Feng Guo from Suzhou University of Science and Technology (College of Chemistry and Life Sciences) have developed a black graphitic carbon nitride/loofah/chitosan hydrogel (BCN/LF/CS) as a highly efficient solar evaporator. This innovative hydrogel utilizes the synergistic effects of evaporation and photocatalysis, showing great potential in seawater desalination and wastewater purification by degrading antibiotics present in the water. The system achieved an optimal evaporation rate of 2.1 kg m⁻² h⁻¹ in 3.5 wt% NaCl solution and maintained a 91.4% tetracycline (TC) degradation efficiency after 6 hours of sunlight exposure. This research has been published in Separation and Purification Technology under the title:

“Construction of black g-C3N4/loofah/chitosan hydrogel as an efficient solar evaporator for desalination coupled with antibiotic degradation.”

Introduction and Motivation

The global ocean spans about 360 million square kilometers, yet millions of people face severe freshwater shortages. Conventional desalination technologies—such as filtration, adsorption, reverse osmosis, and electrodialysis—are often energy-intensive and costly, limiting their use in resource-scarce and arid regions.

Solar-driven interfacial evaporation has emerged as a sustainable method to efficiently produce freshwater, suitable for seawater desalination and wastewater purification. Many researchers have employed photothermal materials (such as metal nanoparticles, semiconductors, and carbon-based materials) to enhance the interface structure and improve evaporation efficiency. However, as industrialization advances, water sources are increasingly contaminated with trace pollutants like antibiotics and microplastics, posing environmental risks and health hazards. Thus, solar-driven evaporation systems should ideally combine seawater desalination with the ability to purify organic pollutants.

Photocatalysis offers a promising solution—it harnesses solar energy to remove organic pollutants without requiring expensive oxidants, making it a low-cost and easy-to-operate process. Combining photocatalysis with photothermal evaporation allows wastewater to be purified while generating clean water. Many existing systems rely on different materials to achieve photothermal and photocatalytic functions, complicating efforts to optimize both water evaporation and pollutant degradation. This research addresses the challenge by developing an integrated photothermal-photocatalytic system, capable of excelling at both evaporation and degradation.

Key Highlights and Design of the BCN/LF/CS Hydrogel

1. Dual Functionality: Photothermal Evaporation and Photocatalytic Degradation

The BCN/LF/CS hydrogel evaporator features dual functions—efficient solar evaporation and photocatalytic degradation of antibiotics.

- Graphitic Carbon Nitride (BCN): A black photothermal material that efficiently converts solar energy into heat for seawater evaporation. Simultaneously, its photocatalytic properties facilitate the degradation of antibiotics such as tetracycline.

- Loofah Fiber (LF) and Chitosan (CS): Provide mechanical stability, hydrophilicity, and a three-dimensional network structure. These components enhance water transport, improve the durability of the hydrogel, and prevent salt accumulation on the evaporation surface.

Excellent Performance and Long-Term Durability

- High Evaporation Rate: The BCN/LF/CS hydrogel evaporator achieved an evaporation rate of 2.1 kg m⁻² h⁻¹ in 3.5 wt% NaCl solution, which is about 20 times higher than natural evaporation.

- Photocatalytic Degradation Efficiency: In sunlight, the hydrogel degraded 91.4% of tetracycline (TC) in a 50 mg/L solution within 6 hours of irradiation.

- Durability: The evaporator maintained stable performance after 15 days of continuous use, demonstrating exceptional long-term stability.

Fabrication Process of BCN/LF/CS Hydrogel

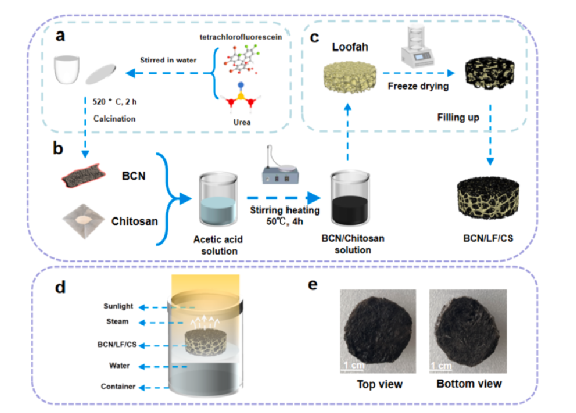

The BCN/LF/CS hydrogel is synthesized through a three-step process:

- Preparation of Black BCN Powder:

- Urea and fluorescein are thoroughly ground and calcined to obtain black BCN powder (Fig. 1a). Compared to traditional carbon nitride (CN), BCN exhibits enhanced light absorption and photothermal effects, making it suitable as both a photothermal material and photocatalyst.

- Preparation of BCN/CS Solution:

- BCN powder and chitosan (CS) are dispersed in acetic acid and stirred magnetically to form a homogeneous solution (Fig. 1b).

- Hydrogel Assembly:

- The mixed solution is poured into loofah fiber (LF)-containing molds, which are freeze-dried to remove all solvents, forming the final BCN/LF/CS hydrogel (Fig. 1c).

The working principle of the hydrogel (Fig. 1d) demonstrates its dual role as a solar evaporator and antibiotic degradation system, showing significant potential for seawater desalination and wastewater purification.

Performance of BCN/LF/CS Hydrogel: Solar Evaporation and Degradation

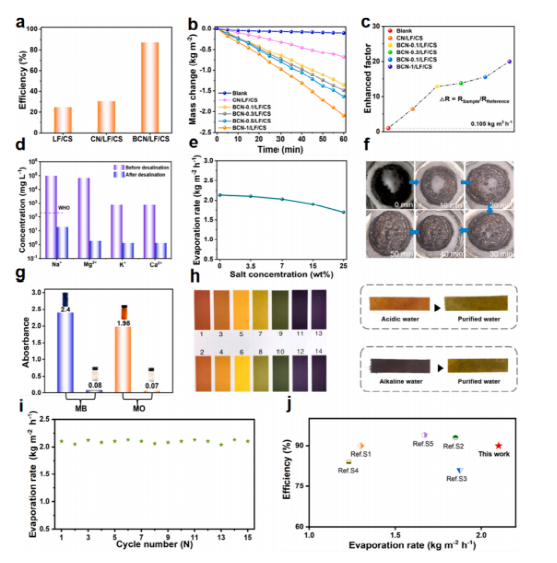

The solar evaporation efficiency, salt resistance, and long-term stability of the BCN/LF/CS hydrogel were evaluated.

1. Photothermal Conversion Efficiency

- The light-to-heat conversion efficiency is crucial for evaporation. As shown in Fig. 2a, the LF/CS hydrogel’s photothermal efficiency increased to 24.92%, demonstrating that LF enhances light capture.

- Introducing CN materials further improved conversion efficiency. The final BCN/LF/CS hydrogel significantly outperformed conventional evaporators in both evaporation rate and photothermal conversion.

2. Salt Resistance and Stability

- The porous structure and excellent water-wicking properties of the BCN/LF/CS hydrogel prevent salt particle accumulation through thermal capillary action, ensuring stable performance under high salinity conditions.

- The hydrogel maintained high evaporation efficiency even after prolonged exposure to saltwater, showcasing strong durability.

3. Green and Sustainable Water Purification

- UV-visible spectroscopy tests showed that the condensate from the evaporator contained no organic pollutants (Fig. 2g).

- Regardless of whether the input water was acidic or alkaline, the pH of the purified water was nearly neutral, meeting discharge standards (Fig. 2h).

Photocatalytic Degradation Performance

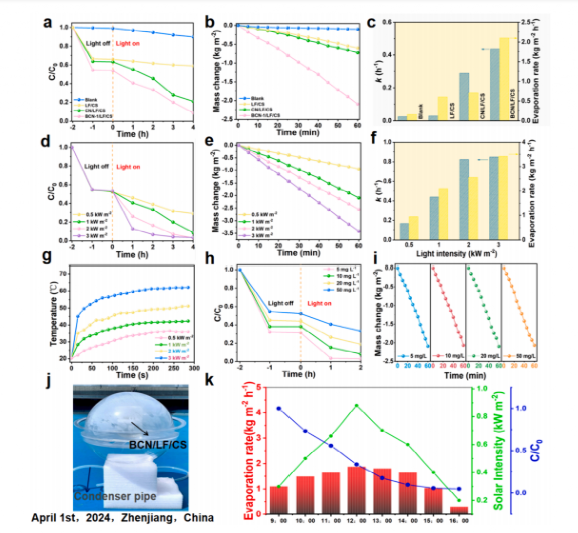

The photocatalytic degradation of antibiotics and evaporation performance under various conditions were also tested (Fig. 3).

1. Degradation Efficiency

- The hydrogel exhibited 92% tetracycline degradation efficiency in sunlight, outperforming CN/LF/CS-based systems, which achieved 79% degradation.

2. Impact of Sunlight Intensity

- Stronger sunlight enhanced both the degradation rate and evaporation efficiency, as increased surface temperature promoted charge separation and accelerated water molecule movement.

3. Adaptability to Different TC Concentrations

- The hydrogel maintained stable performance across various initial tetracycline concentrations, with little effect on evaporation efficiency.

4. Practical Applications

- In real-world scenarios, the evaporator effectively collected fresh water while reducing antibiotic concentrations in wastewater, proving its potential for practical applications.

Conclusion and Future Prospects

The BCN/LF/CS hydrogel evaporator combines photothermal evaporation and photocatalytic degradation, making it a powerful tool for seawater desalination and organic pollutant removal. In this composite hydrogel, BCN converts solar energy into heat while generating photo-induced electrons to degrade organic pollutants. The LF and CS components enhance stability, water transport, and salt resistance.

The experimental results demonstrate that the evaporator achieves an evaporation rate of 2.1 kg m⁻² h⁻¹ in 3.5 wt% NaCl solution, with 91.4% tetracycline degradation in 6 hours.

This research offers new insights into the development of photothermal-photocatalytic systems and holds significant promise for wastewater purification in the future.