Record-Breaking Thermal Conductivity in Graphene: A Breakthrough!

Overview

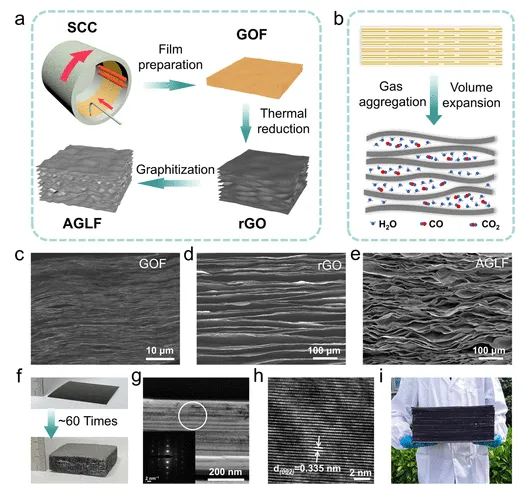

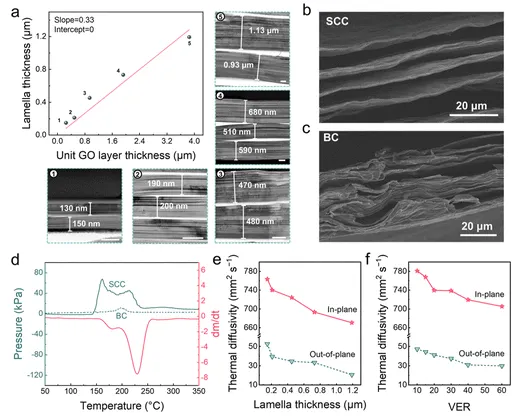

High thermal conductivity and flexible thermal interface materials (TIMs) are ideal for heat dissipation in modern electronics. A research team led by Prof. Wencai Ren from the Institute of Metal Research, Chinese Academy of Sciences, recently published a paper in ACS Nano titled “Highly Thermally Conductive and Flexible Thermal Interface Materials with Aligned Graphene Lamella Frameworks.” This study describes a novel approach to creating an aligned graphene lamella framework (AGLF) by manipulating the thermal expansion behavior of graphene oxide films using scanned centrifugal casting. The result is a highly ordered structure with precise control over lamella thickness, porosity, and graphene-to-graphene contact.

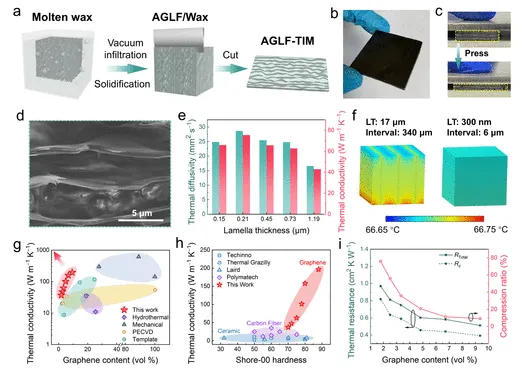

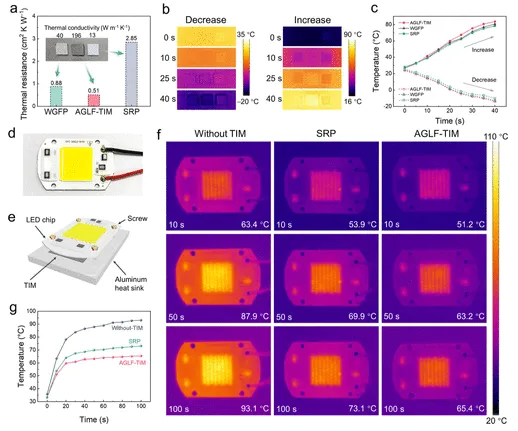

The rational design of AGLF achieves a balance between thermal conductivity and flexibility in TIMs. The AGLF-based TIM (AGLF-TIM), with just 9.4 Vol% graphene content, exhibits a record thermal conductivity of 196.3 W m⁻¹ K⁻¹—approximately four times higher than previously reported TIMs with similar graphene content. Additionally, its flexibility rivals that of commercial TIMs. In LED devices, using AGLF-TIM reduces temperatures by 8°C compared to high-performance commercial TIMs. This research offers a new strategy for the controlled fabrication of graphene macroscopic structures, highlighting the potential of graphene frameworks in thermal management.

Visual Summary

- Figure 1: Fabrication and structural characterization of AGLF.

- Figure 2: Mechanism of AGLF formation.

- Figure 3: Thermal and mechanical performance of AGLF-TIMs.

- Figure 4: Comparison of heat dissipation using AGLF-TIM, WGFP, and SRP.

Summary

The study finds that during thermal reduction, gases generated from SCC-prepared GOF tend to accumulate at the interfaces between adjacent layers. This allows for precise control over GOF expansion, resulting in highly crystalline AGLF with optimized lamella thickness, porosity, and graphene contact post-graphitization. The well-designed AGLF-TIM achieves an impressive thermal conductivity of 196.3 W m⁻¹ K⁻¹ at 9.4 Vol% graphene content, a low thermal resistance of 0.51 cm² K W⁻¹ at an initial thickness of 2 mm, and flexibility comparable to commercial TIMs. Compared to top commercial TIMs, AGLF-TIM reduces LED device temperatures by an additional 8°C. This work provides a framework for controlled graphene macrostructure fabrication, showcasing graphene’s potential as a filler framework in thermal management applications.

Reference: https://doi.org/10.1021/acsnano.4c06952