Efficient and Cost-Effective: How Carbon Materials Optimize Lithium-Ion Battery Manufacturing Processes

Lithium-ion batteries (LIBs) have become the cornerstone of modern energy storage solutions, powering everything from portable electronics to electric vehicles (EVs) and renewable energy storage systems. As the demand for more efficient, long-lasting, and affordable batteries continues to grow, one of the most significant areas of research has focused on optimizing the manufacturing processes of LIBs. Among the various strategies for improving battery performance and reducing costs, carbon materials such as graphene, carbon nanotubes (CNTs), and carbon nanofibers have emerged as key players in transforming the lithium-ion battery industry. These materials not only enhance the performance of the batteries but also contribute to reducing manufacturing costs, making them a crucial element in the evolution of energy storage technologies.

The Role of Carbon Materials in Lithium-Ion Battery Manufacturing

Carbon-based materials, including graphene, CNTs, and carbon black, have long been utilized in lithium-ion battery electrodes due to their unique properties. These materials are known for their excellent electrical conductivity, mechanical strength, and thermal stability, making them essential for improving the performance and efficiency of LIBs. As manufacturers strive to optimize the production processes of lithium-ion batteries, carbon materials are being increasingly integrated into various stages of battery fabrication, from electrode preparation to overall cell design.

Key Properties of Carbon Materials for Lithium-Ion Batteries

To understand how carbon materials can optimize the manufacturing processes of lithium-ion batteries, it is essential to first explore the key properties of these materials that contribute to battery performance:

1. Electrical Conductivity

One of the most important attributes of carbon materials in lithium-ion batteries is their exceptional electrical conductivity. Graphene, CNTs, and carbon black are all highly conductive, allowing for efficient electron flow within the battery’s anode and cathode electrodes. This property is critical for fast charge/discharge cycles and high energy density. Enhanced conductivity reduces internal resistance, which in turn helps in reducing energy losses during both charging and discharging processes, leading to faster charging times and improved efficiency.

2. High Surface Area

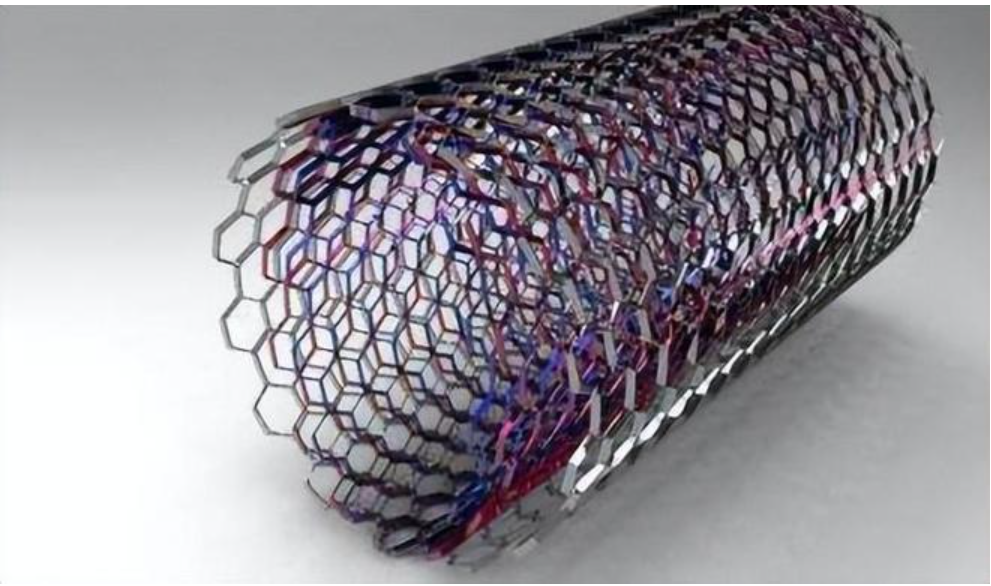

Carbon materials such as graphene and CNTs have a high surface area due to their unique structures (e.g., 2D sheet-like structures in graphene and long, tubular configurations in CNTs). This increased surface area allows for more active sites where lithium ions can intercalate, improving the overall capacity and cycle life of the battery. More active sites also enable higher ion diffusion rates, which can enhance the battery’s performance, particularly in high-power applications like electric vehicles and grid energy storage systems.

3. Mechanical Strength and Flexibility

The mechanical strength of carbon materials is another critical factor in lithium-ion battery manufacturing. Carbon-based materials can reinforce the electrodes, making them more resilient to stress during charge/discharge cycles. This is particularly important for preventing material degradation, ensuring the longevity of the battery. Additionally, carbon nanomaterials like CNTs provide flexibility, which allows for the creation of lighter and more durable battery components, reducing overall production costs.

4. Thermal Stability

Carbon materials are highly thermally stable, which allows them to perform well under the high temperatures typically generated during fast charging and discharging. In lithium-ion batteries, efficient thermal management is crucial to avoid overheating and prevent safety issues such as thermal runaway. Carbon materials help to dissipate heat more efficiently, improving the overall safety and reliability of the battery.

Optimizing Lithium-Ion Battery Manufacturing Processes Using Carbon Materials

The integration of carbon materials into the lithium-ion battery manufacturing process offers several opportunities for optimization, both in terms of performance and cost reduction. Below are the primary ways carbon materials contribute to optimizing LIB manufacturing:

1. Improving Electrode Materials

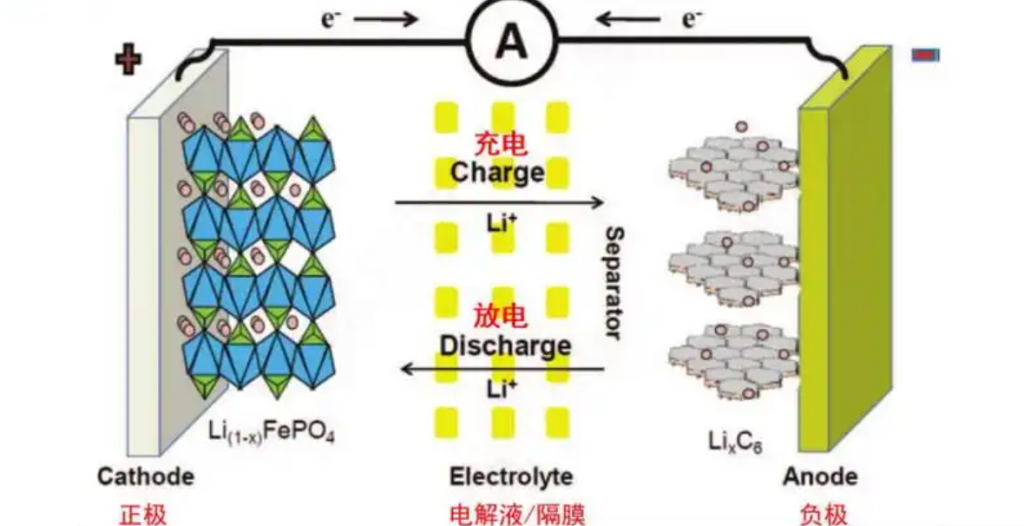

In lithium-ion batteries, the anode and cathode materials are the most critical components determining overall performance. Carbon materials can be incorporated into both the anode and cathode to improve conductivity and enhance energy storage capabilities.

- Graphene and Graphene-Based Composites: Graphene, due to its high electrical conductivity and surface area, has shown great promise as an anode material or as a conductive additive in traditional anode materials like graphite. Graphene-based composites, such as graphene-graphite or graphene-silicon, can increase the capacity and efficiency of the anode, allowing for faster charging times and better energy density. Additionally, graphene’s high mechanical strength helps maintain the structural integrity of the anode material during cycling, which improves the cycle life of the battery.

- Carbon Nanotubes (CNTs): CNTs are often used in conjunction with other materials like silicon to enhance the performance of anodes. Silicon has a much higher capacity than graphite but suffers from significant volume expansion during charging, which can cause the material to degrade. CNTs can be used as a conductive network to improve the mechanical properties and enhance the conductivity of the anode, while also reducing the risk of material failure due to expansion.

- Carbon Black as Conductive Additives: Carbon black is a widely used conductive additive in lithium-ion battery electrodes, typically added to the anode or cathode to enhance conductivity. By optimizing the proportion of carbon black in the electrode mix, manufacturers can reduce the overall resistance of the battery, resulting in better performance and faster charge/discharge cycles.

2. Cost Reduction through Material Substitution

One of the key benefits of incorporating carbon materials into the manufacturing process of lithium-ion batteries is the potential for cost reduction. Carbon materials such as graphene and CNTs are increasingly being produced at lower costs due to advancements in manufacturing techniques. This is crucial for scaling up the production of lithium-ion batteries, especially for applications such as electric vehicles where cost efficiency is paramount.

- Reduced Use of Precious Metals: Traditionally, LIBs rely on expensive metals such as cobalt and nickel for the cathode materials. By using carbon-based composites, it is possible to reduce the amount of these precious metals required in the battery, or in some cases, eliminate them altogether. For example, researchers have developed cathodes based on carbon nanomaterials, which can replace or reduce the need for expensive transition metals. This substitution lowers the overall cost of battery production while maintaining or even improving battery performance.

- Lower Manufacturing Costs for Electrode Production: The integration of carbon materials such as graphene and CNTs into the electrodes also helps to reduce the overall costs of electrode production. For instance, the use of carbon nanotubes or graphene as conductive additives reduces the amount of binder materials required in electrode fabrication. This leads to simpler manufacturing processes, reducing production time and associated costs.

3. Enhancing Energy Density and Cycle Life

Incorporating carbon materials into the electrodes of lithium-ion batteries not only improves conductivity but also increases the overall energy density and cycle life of the battery. These factors directly contribute to the battery’s performance, making it more suitable for high-demand applications like electric vehicles and grid storage systems.

- Graphene-Silicon Composite Anodes: One of the most promising developments in lithium-ion battery technology is the use of graphene-silicon composite anodes. Silicon has a much higher capacity than graphite but suffers from significant volume expansion during cycling, which can cause the material to crack and degrade. By combining silicon with graphene, researchers have been able to create composite anodes that offer both high capacity and improved cycle stability. This increases the overall energy density of the battery while improving its cycle life.

- Improved Thermal Management: Carbon materials’ excellent thermal conductivity helps to prevent overheating during fast charging and discharging cycles. As the demand for faster charging increases, effective thermal management becomes crucial for ensuring battery safety and longevity. The incorporation of carbon materials helps dissipate heat more effectively, preventing overheating and thermal runaway while improving the safety and stability of the battery.

4. Environmental and Sustainability Considerations

Another benefit of carbon-based materials in lithium-ion battery manufacturing is their potential to contribute to sustainability. Carbon materials like graphene are derived from natural sources like graphite or biomass, which makes them a more sustainable option compared to metals like cobalt or nickel. Additionally, the use of carbon-based materials can enhance the recyclability of the battery, as carbon is easier to recover and reuse in the recycling process.

Data and Case Studies

Several studies and real-world applications provide evidence of the positive impact of carbon materials on the performance and cost of lithium-ion batteries. For example:

- Graphene-Based Batteries: Researchers at the University of Manchester have demonstrated that graphene-based anodes can increase the energy density of lithium-ion batteries by up to 50%, while also improving the charging speed. This has significant implications for industries such as electric vehicles, where fast charging is a key requirement.

- Carbon Nanotube-Enhanced Batteries: A study by Stanford University showed that using carbon nanotubes in combination with silicon anodes could increase the charge-discharge rate by up to 300% compared to conventional graphite anodes. This significant improvement in charging speed is particularly important for electric vehicle applications.

- Cost Savings in Large-Scale Production: Companies like Tesla and BYD have been actively working on integrating carbon materials into their battery designs to reduce manufacturing costs. Tesla’s Gigafactory, for example, is experimenting with carbon-based additives to improve the conductivity and reduce the reliance on expensive raw materials.

Conclusion

The integration of carbon materials such as graphene, carbon nanotubes, and carbon black into the lithium-ion battery manufacturing process represents a transformative approach to improving battery performance, reducing costs, and enhancing sustainability. These materials not only enhance the electrical conductivity, energy density, and cycle life of the batteries but also contribute to lowering the overall cost of production. As research continues to advance and manufacturing techniques improve, carbon materials will play an increasingly important role in optimizing the lithium-ion battery manufacturing process, paving the way for more efficient, affordable, and sustainable energy storage solutions.