Carbon Nanotubes: Synthesis, Properties, and Commercial Applications

Introduction

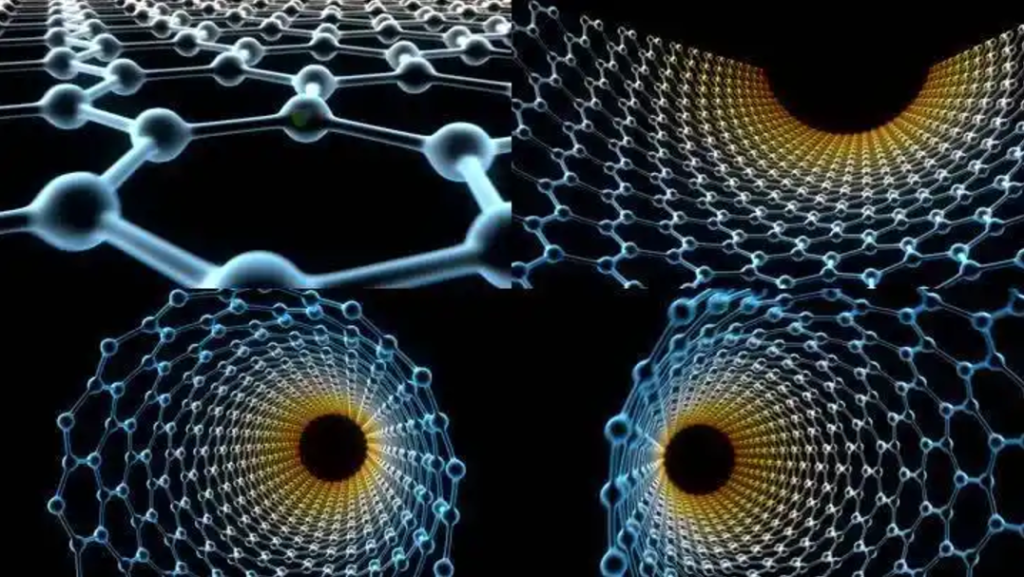

Carbon Nanotubes (CNTs) are one of the most significant advancements in nanotechnology. Since their discovery, CNTs have gained attention for their unique mechanical, electrical, and thermal properties. These tubular structures, composed of rolled-up sheets of graphene, are classified into single-walled carbon nanotubes (SWCNTs), multi-walled carbon nanotubes (MWCNTs), and few-walled carbon nanotubes (FWCNTs). Their versatility has enabled widespread adoption across industries, including electronics, energy, healthcare, and construction.

Synthesis of Carbon Nanotubes

CNTs are primarily synthesized through methods that use metal catalysts and carbon precursors. The choice of method and precursor significantly affects the morphology, purity, and scalability of the CNTs.

1. Catalysts and Precursors

The growth of CNTs requires a carbon source, a catalyst, and a specific reaction environment. Common catalysts include transition metals like iron (Fe), cobalt (Co), and nickel (Ni), often supported by substrates such as silica (SiO₂) or alumina (Al₂O₃).

Catalyst Types

- Iron-based (Fe-based): Preferred for high-yield production of MWCNTs.

- Cobalt-based (Co-based): Produces SWCNTs with uniform diameters.

- Nickel-based (Ni-based): Facilitates control over CNT diameter.

- Metal oxides: Such as Fe₂O₃ or Co₃O₄, offering stability during high-temperature processes.

Carbon Precursors

- Gaseous: Hydrocarbons like methane (CH₄), ethylene (C₂H₄), and acetylene (C₂H₂).

- Liquid: Aromatics like benzene and toluene.

- Solid: Coal tar and graphite.

2. Synthesis Methods

Several techniques are used for CNT production, each with unique advantages:

Chemical Vapor Deposition (CVD)

- Process: Hydrocarbon gases decompose over a metal catalyst at 500-1000°C, forming CNTs.

- Features: High scalability, controlled growth, and cost-effectiveness.

- Applications: Preferred for industrial-scale production of both SWCNTs and MWCNTs.

Arc Discharge Method

- Process: Graphite electrodes are vaporized in a high-temperature arc.

- Features: Produces high-quality CNTs but is less scalable.

- Applications: Primarily used in research for SWCNTs.

Laser Ablation

- Process: A graphite target is vaporized using high-power lasers in an inert gas.

- Features: Yields high-purity SWCNTs but is expensive.

- Applications: Research-grade applications requiring minimal defects.

Floating Catalyst CVD

- Process: Utilizes catalysts like ferrocene in a gas phase for CNT growth.

- Features: Enables large-scale production of aligned CNT arrays.

- Applications: Electronics and composite materials.

Key Characteristics of Carbon Nanotubes

CNTs exhibit extraordinary characteristics that set them apart from traditional materials.

1. Structural Features

- SWCNTs: Diameter of ~1-2 nm; single graphene layer rolled into a cylinder.

- MWCNTs: Diameter ranges from 2 nm to 100 nm; consists of multiple concentric graphene layers.

- Length: CNTs can range from micrometers to several millimeters.

2. Mechanical Properties

- Tensile Strength: ~50-200 GPa, making them 100 times stronger than steel.

- Elastic Modulus: ~1 TPa, offering high stiffness.

- Flexibility: Despite their strength, CNTs are lightweight and flexible.

3. Electrical Properties

- Conductivity: CNTs can exhibit metallic or semiconducting behavior depending on their chirality.

- Current Density: CNTs can carry currents up to 1000 times higher than copper.

4. Thermal Properties

- Conductivity: CNTs exhibit thermal conductivity of ~3500 W/m·K.

- Stability: High thermal stability, withstanding temperatures up to 2800°C in vacuum.

5. Chemical Properties

- Reactivity: CNTs can be functionalized with various chemical groups to enhance compatibility with polymers or solvents.

- Adsorption: High surface area makes them ideal for adsorbing gases or pollutants.

Commercial Applications of Carbon Nanotubes

1. Energy Storage

CNTs are revolutionizing energy storage technologies due to their high conductivity, surface area, and mechanical strength.

Lithium-Ion Batteries

- Role: Used as conductive additives in anode and cathode materials.

- Advantages: Improve battery lifespan, charge capacity, and energy density.

- Examples: Panasonic and Tesla integrate CNT-enhanced batteries in electric vehicles (EVs).

Supercapacitors

- Role: CNTs serve as electrode materials, enabling high power density.

- Advantages: Faster charging times and extended cycle life.

- Applications: Renewable energy systems, portable electronics.

2. Electronics and Semiconductors

The exceptional electrical properties of CNTs have made them indispensable in electronics.

Transparent Conductive Films

- Role: Replace traditional ITO electrodes in touchscreens and displays.

- Advantages: Flexible, lightweight, and more durable.

- Examples: Used in OLED and e-paper displays.

Interconnects and Transistors

- Role: CNTs function as interconnect materials in microchips or as components in transistors.

- Advantages: Reduce resistance, increase processing speed, and improve heat dissipation.

3. Composite Materials

CNTs are widely used as additives in composites to enhance mechanical, electrical, and thermal performance.

Polymer Composites

- Role: Reinforce plastics for aerospace, automotive, and construction industries.

- Advantages: Provide lightweight alternatives with high strength and durability.

- Examples: Boeing incorporates CNT composites in aircraft parts.

Concrete Additives

- Role: Improve crack resistance and strength in concrete.

- Applications: High-performance buildings and infrastructure.

4. Healthcare and Biotechnology

CNTs have found applications in drug delivery, diagnostics, and tissue engineering.

Drug Delivery Systems

- Role: Functionalized CNTs act as carriers for targeted drug delivery.

- Advantages: Enhanced bioavailability and controlled release.

- Applications: Cancer treatment and gene therapy.

Biosensors

- Role: CNT-based sensors detect glucose, cholesterol, and other biomolecules.

- Advantages: High sensitivity and rapid response.

- Examples: Portable glucometers using CNT technology.

5. Environmental Applications

CNTs contribute to sustainability efforts through water purification and energy efficiency.

Water Treatment

- Role: CNT membranes adsorb heavy metals, organic pollutants, and pathogens.

- Advantages: High filtration efficiency and chemical resistance.

- Applications: Used in desalination plants and wastewater treatment.

Air Purification

- Role: CNT filters remove particulates and toxic gases.

- Applications: Air purification systems for industrial and residential use.

6. Thermal Management

CNTs are employed in thermal management systems for electronics and LEDs.

Thermal Interface Materials (TIMs)

- Role: CNTs enhance heat dissipation in semiconductors and LEDs.

- Advantages: Reduce overheating, improving device lifespan.

- Examples: Integrated into CPUs, GPUs, and photovoltaic cells.

7. Advanced Textiles

CNTs are incorporated into fabrics to create advanced textiles with multifunctional properties.

Conductive Fabrics

- Role: CNTs enable the integration of sensors into clothing.

- Applications: Wearable electronics, smart textiles for health monitoring.

Protective Gear

- Role: Enhance strength and conductivity in fabrics.

- Examples: Anti-static suits for sensitive environments.

Conclusion

Carbon nanotubes, with their exceptional properties, have transformed multiple industries. Advances in synthesis methods and scalable production have enabled CNTs to be used in commercial applications, from energy storage to environmental sustainability. As research continues, CNTs are expected to drive further innovations, making them indispensable in the future of technology.