Graphene Gas Sensors: Revolutionizing the Detection of Methane, Hydrogen, Carbon Dioxide, and More

The ability to monitor and detect gases accurately and efficiently is critical in industries ranging from energy and environmental protection to healthcare and industrial safety. Traditional gas sensors, while effective, often struggle with limitations such as slow response times, high power consumption, and reduced sensitivity in challenging conditions. Enter graphene-based gas sensors, a groundbreaking innovation leveraging the extraordinary properties of graphene to offer unmatched sensitivity, rapid response, and versatility in detecting gases like methane (CH₄), hydrogen (H₂), and carbon dioxide (CO₂).

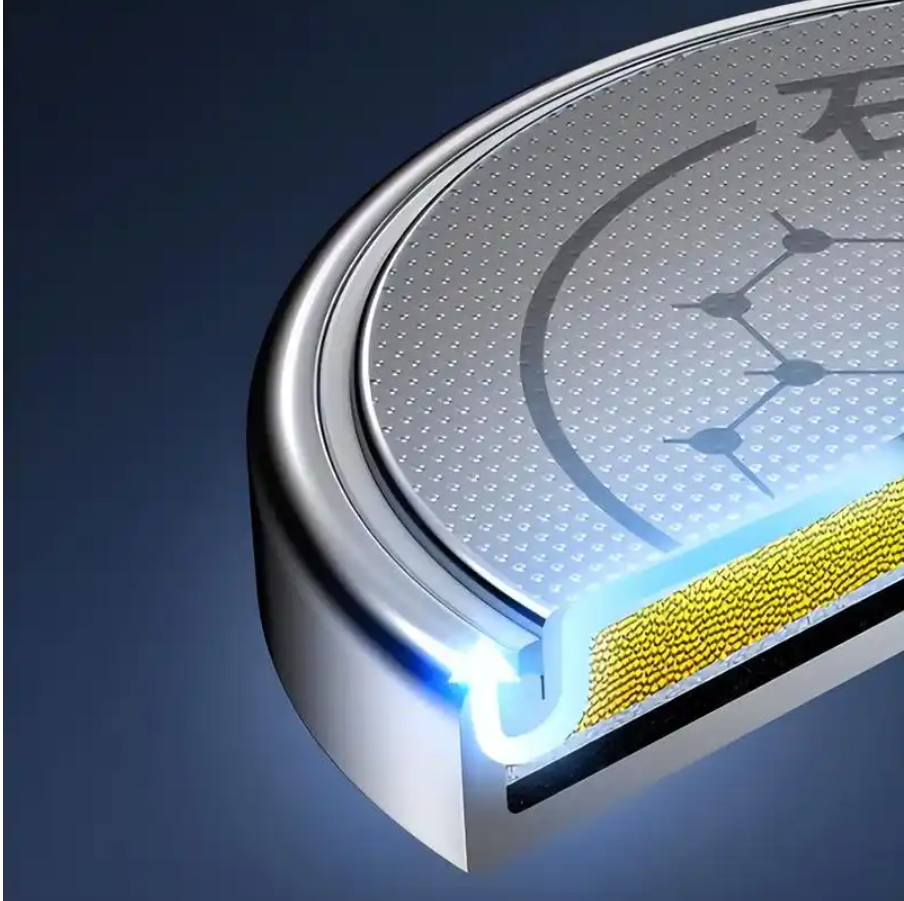

The Unique Properties of Graphene for Gas Sensing

Graphene’s exceptional attributes make it a game-changer in gas detection:

- Ultra-High Surface Area: Its two-dimensional structure provides a vast surface for gas molecules to interact with.

- Exceptional Electrical Conductivity: Small changes in electron transfer during gas adsorption lead to measurable changes in conductivity.

- High Sensitivity: Graphene can detect gases at concentrations as low as parts per billion (ppb).

- Thermal and Chemical Stability: It operates effectively under a wide range of environmental conditions.

- Functionalization Versatility: The addition of metal nanoparticles, oxides, or polymers enhances selectivity for specific gases.

Applications of Graphene Gas Sensors

1. Methane Detection

Methane is a potent greenhouse gas and a major component of natural gas. Detecting methane leaks is critical for environmental protection and industrial safety.

- Example: Graphene sensors functionalized with palladium nanoparticles have shown remarkable sensitivity to methane, detecting concentrations at ppb levels with rapid response times.

2. Hydrogen Monitoring

Hydrogen, widely used in industries such as fuel cells and chemical manufacturing, is highly flammable. Monitoring hydrogen leaks is vital for preventing accidents.

- Example: Reduced graphene oxide (rGO) sensors doped with platinum or palladium enable selective and rapid hydrogen detection, even in the presence of other gases.

3. Carbon Dioxide Sensing

Monitoring CO₂ levels is crucial for environmental control, indoor air quality, and industrial processes.

- Example: Functionalized graphene oxide sensors detect CO₂ with high precision and operate efficiently at room temperature, making them suitable for energy-saving applications.

4. Toxic Gas Detection

Graphene sensors are also effective in detecting toxic gases like ammonia (NH₃), nitrogen dioxide (NO₂), and sulfur dioxide (SO₂), ensuring industrial and environmental safety.

- Example: A graphene-based sensor achieved rapid NO₂ detection at concentrations as low as 10 ppb, making it suitable for air quality monitoring.

Advantages of Graphene Gas Sensors

Graphene-based gas sensors outperform traditional sensors in several ways:

- High Sensitivity and Selectivity: Detect even trace amounts of gases with high specificity.

- Fast Response and Recovery Times: Near-instantaneous detection and reset enable real-time monitoring.

- Low Power Consumption: Operate efficiently, suitable for battery-powered and IoT-enabled devices.

- Scalability and Cost-Effectiveness: Advancements in graphene production are lowering costs, making large-scale deployment feasible.

- Wide Operating Range: Perform reliably under extreme temperatures and humidity levels.

State-of-the-Art Technologies and Products

1. Portable Gas Detectors

Compact, graphene-based gas detectors are revolutionizing field monitoring by offering high sensitivity and portability.

- Use Case: Portable methane sensors for natural gas pipeline inspections.

2. Wearable Gas Sensors

Lightweight and flexible graphene sensors are being integrated into wearable devices for personal safety.

- Use Case: Hydrogen leak monitors for workers in chemical plants.

3. IoT-Enabled Monitoring Systems

Graphene gas sensors are being integrated into IoT networks, enabling real-time data collection and remote monitoring.

- Use Case: Smart CO₂ sensors for HVAC systems to optimize indoor air quality.

4. Industrial Process Monitors

Graphene sensors are incorporated into industrial equipment for continuous gas monitoring during manufacturing.

- Use Case: Sensors detecting toxic gas emissions during chemical processing.

Real-World Case Studies

1. Methane Leak Detection in Energy Infrastructure

A graphene-based methane sensor was deployed to monitor leaks in a natural gas distribution system. The sensor provided real-time data, reducing methane emissions and ensuring regulatory compliance.

2. Hydrogen Safety in Fuel Cell Applications

Graphene hydrogen sensors were integrated into hydrogen fuel stations to monitor for leaks. The sensors demonstrated rapid response and high reliability, ensuring safe operations.

3. Indoor Air Quality Control with CO₂ Monitoring

Graphene sensors were installed in office buildings to monitor CO₂ levels. The data helped optimize ventilation systems, improving employee comfort and energy efficiency.

Challenges and Future Directions

While graphene gas sensors hold immense potential, several challenges remain:

- Scalability in Manufacturing: Producing high-quality, uniform graphene at scale is still a work in progress.

- Long-Term Stability: Ensuring consistent sensor performance over extended periods requires further research.

- Selectivity in Complex Environments: Functionalization strategies must improve to differentiate between gases in mixtures.

- Integration with Existing Systems: Adapting graphene sensors for legacy monitoring systems poses technical challenges.

Future Prospects

- Advanced Functionalization: Research into novel materials for graphene doping will enhance selectivity and sensitivity.

- Miniaturization: Developing nanoscale sensors for applications in microelectronics and personal devices.

- Wider Adoption in IoT: Combining graphene sensors with wireless communication for seamless data transmission.

- Global Environmental Monitoring: Deploying graphene gas sensors in large-scale networks to monitor greenhouse gas emissions.

Conclusion

Graphene-based gas sensors are transforming the field of gas detection, offering unparalleled sensitivity, rapid response times, and the flexibility to detect a wide range of gases, including methane, hydrogen, and carbon dioxide. From environmental monitoring to industrial safety, these sensors address critical challenges and open new possibilities for innovation.

As advancements in graphene production and sensor technology continue, the integration of graphene sensors into industrial systems, IoT platforms, and consumer devices will pave the way for a safer, more sustainable future. The ability to monitor gas concentrations accurately and efficiently is no longer a distant goal but a reality made possible by the extraordinary capabilities of graphene.