Graphene-Enhanced High-Efficiency Hydrogen Compression and Storage Technology

Hydrogen storage is a cornerstone of the hydrogen economy, enabling efficient transport and utilization of this clean energy carrier. Among various storage methods, compression-based hydrogen storage is widely used due to its simplicity and compatibility with existing infrastructure. However, challenges such as energy-intensive compression processes, material durability under high pressures, and volumetric efficiency have driven the need for advanced materials to improve storage performance.

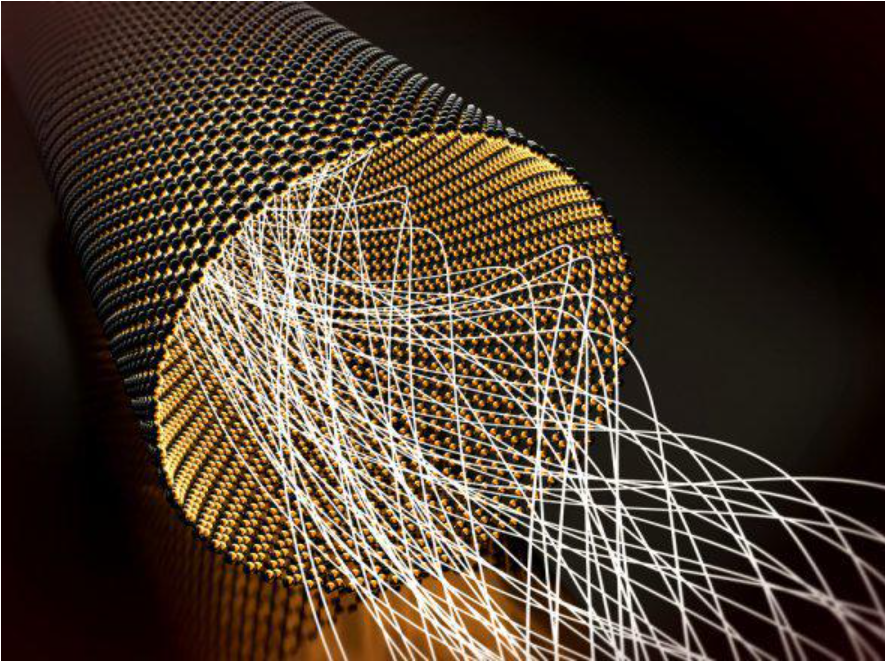

Graphene, with its remarkable mechanical, thermal, and chemical properties, offers a transformative solution for high-efficiency hydrogen compression and storage systems. This article explores the role of graphene in advancing compression-based hydrogen storage technologies, detailing its mechanisms, applications, and recent research breakthroughs.

Challenges in Hydrogen Compression and Storage

- High Energy Consumption:

- Compressing hydrogen to pressures of 350–700 bar requires significant energy, reducing overall system efficiency.

- Material Fatigue and Failure:

- Repeated exposure to high pressures can cause fatigue and failure in storage tanks and pipelines.

- Hydrogen Leakage and Permeability:

- Hydrogen’s small molecular size leads to challenges in containment, resulting in potential leaks.

- Weight and Space Limitations:

- High-pressure storage systems need materials that are both lightweight and strong to optimize space and transport efficiency.

Advantages of Graphene in Hydrogen Compression and Storage

Graphene’s unique properties make it an ideal material to enhance hydrogen compression and storage technologies:

- Exceptional Mechanical Strength:

- Graphene’s tensile strength (up to 130 GPa) reinforces storage systems, improving resistance to high-pressure conditions.

- Barrier Properties:

- Graphene’s impermeability to gases prevents hydrogen leakage, ensuring safe and efficient storage.

- Thermal Conductivity:

- Its high thermal conductivity (~5,000 W/m·K) aids in heat dissipation during the compression process, reducing thermal stress.

- Lightweight Nature:

- Graphene composites are significantly lighter than metals, enabling more compact and efficient storage solutions.

- Hydrogen Adsorption:

- Graphene’s high surface area and tunable surface chemistry enhance hydrogen adsorption, complementing compression-based methods.

Graphene’s Role in Compression-Based Hydrogen Storage

1. Reinforcement of Storage Tanks

- Mechanism:

- Graphene-reinforced polymers and composites improve the structural integrity of high-pressure hydrogen storage tanks, making them more resistant to fatigue and failure.

- Example:

- A graphene-enhanced composite storage tank demonstrated a 30% increase in burst pressure compared to traditional carbon-fiber-reinforced tanks.

2. Hydrogen Permeation Barrier

- Mechanism:

- Single or multi-layer graphene coatings on tank interiors create a gas-impermeable barrier, minimizing hydrogen loss.

- Example:

- Graphene-coated steel tanks showed a 90% reduction in hydrogen permeability over extended storage periods.

3. Heat Management During Compression

- Mechanism:

- Graphene dissipates heat generated during hydrogen compression, preventing overheating and material degradation.

- Example:

- Incorporating graphene into compressor components reduced operational temperatures by 15%, enhancing durability.

4. Hybrid Adsorption-Compression Systems

- Mechanism:

- Graphene-based materials combine physical adsorption with compression to store hydrogen more efficiently at lower pressures.

- Example:

- Nitrogen-doped graphene achieved adsorption capacities of 5 wt% at 77 K, reducing compression energy requirements.

Applications of Graphene in Hydrogen Compression and Storage

1. High-Pressure Storage Tanks

- Graphene Composites:

- Used as a structural material to reduce tank weight while maintaining pressure tolerance.

- Graphene Coatings:

- Applied to prevent hydrogen diffusion and corrosion in metal tanks.

2. Hydrogen Pipelines

- Graphene-Lined Pipelines:

- Provide a durable and leak-proof solution for transporting compressed hydrogen over long distances.

3. Compression Systems

- Graphene-Enhanced Seals:

- Improve the durability and performance of seals in hydrogen compressors, reducing energy loss.

4. Mobile Storage Units

- Lightweight Graphene Composites:

- Enable portable, high-capacity hydrogen storage for applications such as fuel cell vehicles.

Recent Advances in Graphene-Enhanced Hydrogen Storage

- Graphene Nanocomposites:

- Advanced composites with graphene nanoplatelets showed superior pressure tolerance and durability in high-pressure storage tanks.

- Functionalized Graphene for Adsorption:

- Chemical modifications, such as doping with boron or nitrogen, improved hydrogen adsorption properties, reducing reliance on high-pressure compression.

- 3D Graphene Structures:

- Porous graphene frameworks increased volumetric hydrogen storage capacities, providing a complementary approach to compression.

- Graphene-Metal Hybrids:

- Combining graphene with metal hydrides reduced energy requirements for compression by integrating adsorption and compression mechanisms.

Key Performance Metrics

- Pressure Tolerance:

- Graphene-reinforced tanks withstand pressures up to 800 bar, exceeding current industry standards.

- Weight Reduction:

- Graphene composites achieved a 40% weight reduction compared to conventional steel-based storage systems.

- Hydrogen Permeability:

- Multi-layer graphene coatings reduced permeability to nearly zero, ensuring safe long-term storage.

- Thermal Stability:

- Graphene components maintained stability at operational temperatures ranging from -200°C to 200°C.

Challenges and Future Directions

- Scalability:

- Developing cost-effective methods for producing high-quality graphene for large-scale storage applications.

- Integration with Current Infrastructure:

- Ensuring compatibility of graphene-enhanced materials with existing hydrogen storage and distribution systems.

- Comprehensive Testing:

- Conducting long-term durability and safety assessments under real-world conditions.

- Hybrid Systems:

- Exploring the integration of graphene with other advanced materials, such as metal-organic frameworks (MOFs), for hybrid storage solutions.

Conclusion

Graphene’s unique properties position it as a game-changing material in the development of high-efficiency hydrogen compression and storage technologies. By improving the structural integrity, thermal management, and gas containment of storage systems, graphene addresses critical challenges in the hydrogen energy sector.

As research and development continue to unlock graphene’s full potential, it is poised to play a central role in enabling a safe, sustainable, and scalable hydrogen economy.