Graphene Oxide in Composite Materials: Enhancing Coatings, Polymers, and Fiber-Reinforced Materials

Graphene oxide (GO) has become a sought-after additive in composite materials due to its extraordinary mechanical, thermal, and electrical properties. It offers unique opportunities for improving the performance of coatings, polymers, and fiber-reinforced materials, making it a game-changing component across industries such as construction, aerospace, automotive, and sports equipment. This article delves into the advantages, applications, and market trends of graphene oxide in composite materials.

1. High-Performance Coatings

Coatings play a crucial role in protecting surfaces against corrosion, wear, and environmental damage. Adding graphene oxide to coatings significantly enhances their durability, conductivity, and resistance to harsh conditions.

Advantages of GO in High-Performance Coatings

- Corrosion Resistance: GO creates a barrier that prevents moisture, oxygen, and chemicals from penetrating the coating, thereby protecting the underlying material.

- Enhanced Conductivity: GO imparts electrical conductivity, enabling applications in anti-static and conductive coatings.

- Improved Mechanical Strength: GO enhances the scratch resistance and overall durability of coatings.

Applications of GO-Enhanced Coatings

- Anti-Corrosion Coatings: Used in industries such as marine, oil and gas, and construction to protect steel structures and pipelines.

- Conductive Coatings: Applied in electronic devices and energy storage systems, including batteries and capacitors.

- Protective Paints: GO-based paints improve longevity and resistance to environmental damage, ideal for automotive and industrial applications.

Market Trends

The high-performance coatings market is growing due to rising demand for durable and multifunctional solutions. GO-enhanced coatings are increasingly being adopted as sustainable and high-performance alternatives.

2. Polymer Composites

Graphene oxide is widely used in polymer composites to improve the mechanical, thermal, and barrier properties of plastics and rubbers. Its nanoscale structure and compatibility with various polymers make it a versatile reinforcement material.

Advantages of GO in Polymer Composites

- Strength and Flexibility: GO enhances the tensile strength and flexibility of polymer matrices, creating lightweight yet strong materials.

- Thermal Stability: GO improves the thermal resistance of composites, enabling their use in high-temperature environments.

- Gas Barrier Properties: GO layers reduce gas permeability, enhancing the protective capabilities of polymers.

Applications of GO-Enhanced Polymer Composites

- Automotive Components: Lightweight and durable parts such as dashboards, bumpers, and fuel tanks.

- Packaging Materials: High-barrier films for food and pharmaceutical packaging to extend shelf life.

- Industrial Products: Durable seals, gaskets, and hoses with enhanced chemical and thermal resistance.

Market Potential

The polymer composites market is experiencing robust growth due to the demand for lightweight materials in industries such as automotive, packaging, and consumer goods. GO-based composites are poised to play a significant role in replacing conventional materials.

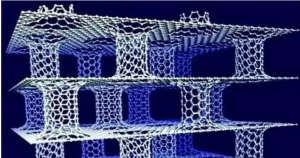

3. Fiber-Reinforced Materials

Fiber-reinforced composites are critical in aerospace, sports, and high-performance applications where strength-to-weight ratios are paramount. Graphene oxide further enhances the performance of these materials by improving interfacial bonding and overall properties.

Advantages of GO in Fiber-Reinforced Materials

- Enhanced Interfacial Bonding: GO improves the adhesion between fibers and the polymer matrix, ensuring better load transfer.

- Improved Mechanical Properties: GO increases tensile and impact strength, creating materials capable of withstanding extreme conditions.

- Thermal Conductivity: GO enhances heat dissipation, reducing thermal degradation in high-performance applications.

Applications of GO-Enhanced Fiber Composites

- Aerospace: Structural components such as fuselage panels, wings, and engine casings.

- Sports Equipment: Lightweight and durable gear, including tennis rackets, bicycles, and skis.

- Wind Energy: Reinforced blades for wind turbines, offering greater efficiency and longevity.

Market Growth

The fiber-reinforced materials market is expanding due to advancements in aerospace, renewable energy, and high-performance sports equipment. GO-enhanced composites provide a competitive edge by delivering superior performance at reduced weights.

Conclusion

Graphene oxide is revolutionizing the composite materials industry by unlocking new levels of performance in coatings, polymers, and fiber-reinforced materials. Its ability to enhance strength, durability, and thermal resistance positions it as a transformative material for diverse applications.

From corrosion-resistant coatings to lightweight automotive parts and high-performance aerospace components, GO is driving innovation across industries. As research and commercialization efforts continue, graphene oxide is set to play an increasingly vital role in creating sustainable and advanced composite solutions that meet the demands of modern technology and industry.