Enhancing Carbon Nanotube Performance through Surface Modification: Functionalization Techniques and Interface Strengthening

Introduction

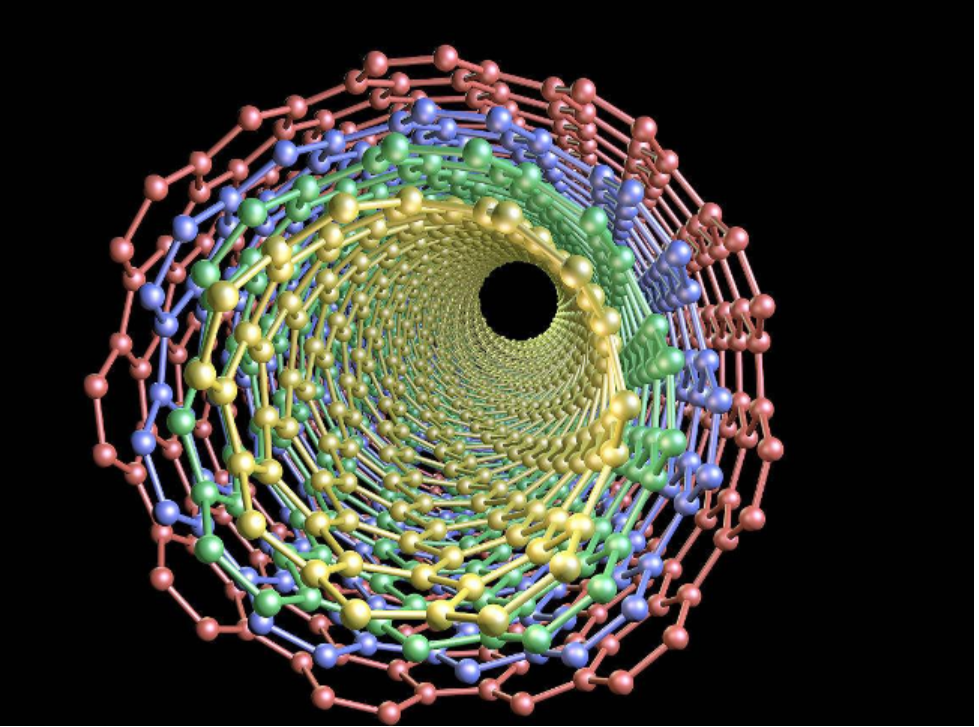

Carbon nanotubes (CNTs) are renowned for their exceptional properties, such as high tensile strength, excellent electrical conductivity, and remarkable thermal stability. Despite these advantages, the inherent hydrophobicity and poor dispersion in various matrices often hinder their full potential in practical applications. Surface modification emerges as a critical strategy to overcome these challenges, enabling better integration and enhanced performance in composite materials. This article delves into the surface modification techniques for CNTs, focusing on functionalization and interface enhancement, and explores their applications across industries.

Surface Modification Techniques for Carbon Nanotubes

Surface modification of CNTs primarily involves altering their chemical and physical properties to improve compatibility with different matrices. Two major approaches include functionalization and physical treatments.

1. Functionalization Techniques

Functionalization involves introducing chemical groups to the surface of CNTs to enhance their compatibility and reactivity. This can be achieved through:

a. Covalent Functionalization

- Oxidation Treatment: Oxidation introduces carboxyl (-COOH) and hydroxyl (-OH) groups to the surface of CNTs, improving their dispersibility in polar solvents and resins. For example, treating CNTs with nitric acid or a sulfuric-nitric acid mixture results in better integration with epoxy matrices for composite applications.

- Amine Functionalization: Amine groups (-NH2) can be grafted onto CNTs to enhance interactions with polymers like polyamide or polyurethane. Studies show that amine-functionalized CNTs increase tensile strength by up to 30% in polymer composites.

b. Non-Covalent Functionalization

- Surfactant Wrapping: Surfactants like sodium dodecyl sulfate (SDS) adsorb onto the CNT surface, improving dispersion in aqueous and organic solutions without altering the intrinsic structure of CNTs.

- Polymer Wrapping: Polymers such as polyethylene glycol (PEG) wrap around CNTs, enhancing compatibility with hydrophilic or hydrophobic matrices depending on the polymer type.

2. Physical Treatments

Physical treatments modify CNT surfaces without involving chemical reactions. Examples include:

- Plasma Treatment: Exposing CNTs to plasma introduces functional groups or roughens the surface to improve adhesion with matrices.

- Irradiation: Electron or gamma irradiation creates defects on CNT surfaces, facilitating better bonding in composites.

Applications of Surface-Modified Carbon Nanotubes

Surface-modified CNTs find extensive use across diverse industries, where enhanced dispersion and improved interfacial properties are crucial.

1. Polymer Composites

In polymer composites, CNTs act as reinforcing agents to improve mechanical, electrical, and thermal properties. Surface modification ensures better bonding between CNTs and polymer matrices.

- Case Study: Epoxy composites with carboxyl-functionalized CNTs exhibit a 50% increase in tensile strength and a 20% improvement in thermal conductivity compared to unmodified CNT composites.

- Applications: Aerospace, automotive, and consumer electronics industries use CNT-enhanced composites for lightweight, high-strength components.

2. Energy Storage Devices

Surface-modified CNTs improve the performance of batteries, supercapacitors, and fuel cells.

- Li-ion Batteries: Amine-functionalized CNTs are used as conductive additives in electrodes, enhancing the specific capacity and cycling stability. Data shows that incorporating 2% functionalized CNTs increases energy density by 15%.

- Supercapacitors: CNTs with oxygen-rich functional groups improve electrode wettability, leading to higher capacitance and energy density.

3. Biomedical Applications

Functionalized CNTs are increasingly used in drug delivery, bioimaging, and tissue engineering due to their enhanced biocompatibility.

- Drug Delivery: PEG-functionalized CNTs enable efficient drug loading and controlled release, reducing side effects and improving therapeutic outcomes.

- Tissue Engineering: Modified CNTs are integrated into scaffolds to promote cell adhesion and growth, supporting regenerative medicine initiatives.

4. Electronics and Conductive Materials

Surface modification of CNTs ensures uniform dispersion in conductive inks and composites for electronic applications.

- Flexible Electronics: Surfactant-wrapped CNTs are used in transparent conductive films, essential for touchscreens and wearable devices.

- EMI Shielding: Composites with surface-modified CNTs offer superior electromagnetic interference (EMI) shielding properties for sensitive electronics.

Data-Driven Analysis of Surface-Modified CNTs

To quantify the impact of surface modification, experimental studies and industrial applications provide compelling data:

- Dispersion Metrics: Functionalized CNTs show a dispersion improvement of 70%-80% in water-based and solvent-based systems compared to unmodified CNTs.

- Composite Strength: Adding 1 wt% of functionalized CNTs to polymer matrices can increase tensile strength by up to 50% and modulus by 40%.

- Thermal Conductivity: CNT composites exhibit a 300% increase in thermal conductivity when functionalized with oxygen-containing groups.

Advantages of Surface-Modified CNTs

- Improved Compatibility: Functional groups enhance the interaction between CNTs and various matrices.

- Enhanced Performance: Modified CNTs significantly boost the mechanical, thermal, and electrical properties of composites.

- Wider Application Range: Surface-modified CNTs enable integration into diverse industries, from energy storage to biomedicine.

Conclusion

Surface modification is a transformative approach to unlocking the full potential of carbon nanotubes in various applications. By employing advanced functionalization techniques and focusing on specific industry needs, manufacturers can leverage the superior properties of CNTs to drive innovation and deliver high-performance solutions. As the market for CNT-based products expands, surface modification will remain a cornerstone of their widespread adoption and success.

Keywords

Carbon Nanotube Surface Modification, CNT Functionalization, Polymer Composites, Energy Storage, Biomedical Applications, Flexible Electronics, Dispersion Improvement, Thermal Conductivity, Interface Strengthening, Advanced Materials.