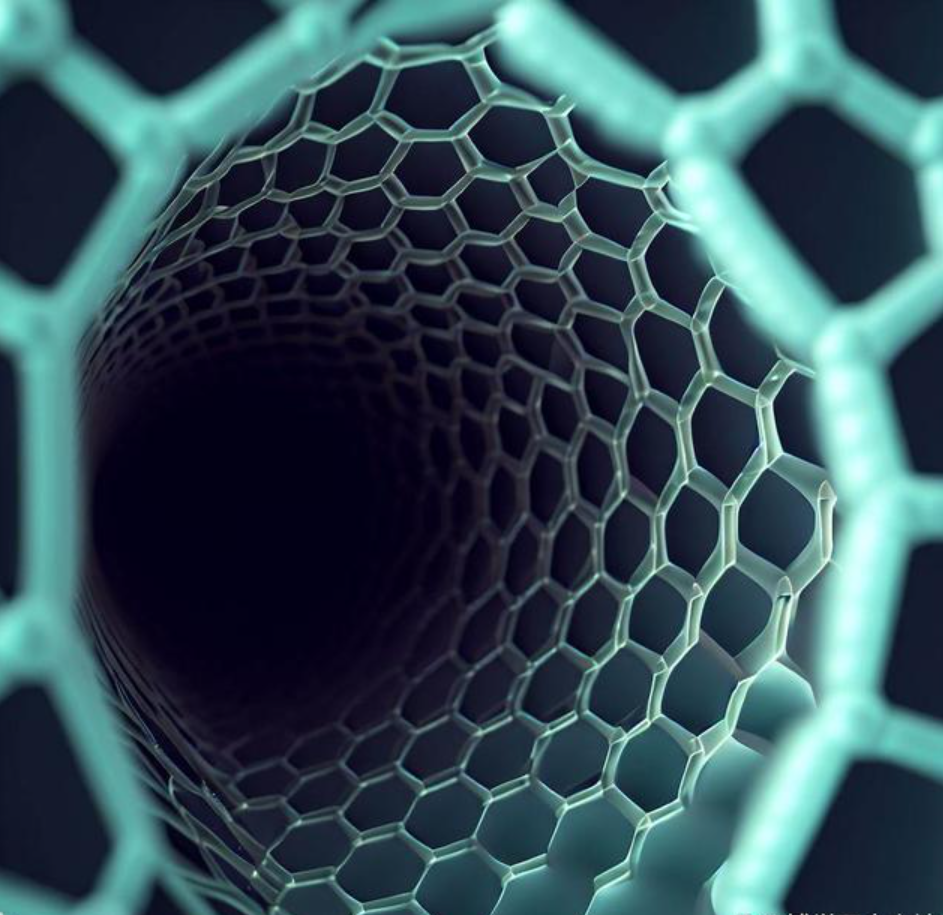

Latest Research Progress in Performance Optimization of Single-Walled Carbon Nanotubes (SWCNTs)

Single-walled carbon nanotubes (SWCNTs) are considered one of the most promising nanomaterials due to their remarkable electrical, thermal, and mechanical properties. However, despite their immense potential, achieving consistent and enhanced performance across various applications remains a challenge. The optimization of SWCNTs in terms of conductivity, thermal conductivity, mechanical properties, and dispersion is an active area of research. This article discusses the latest techniques and advancements aimed at improving these critical properties of SWCNTs, including doping, purification, and dispersion improvement strategies.

1. Electrical Conductivity Optimization

SWCNTs possess intrinsic electrical conductivity, but various factors like defects, chirality, and impurity content can hinder their electrical performance. Researchers are exploring several techniques to enhance the conductivity of SWCNTs for use in applications such as transistors, sensors, and energy storage devices.

1.1. Doping for Conductivity Enhancement

- Doping with Heteroatoms: Introducing heteroatoms such as nitrogen (N), boron (B), or phosphorus (P) into the carbon nanotube structure has been shown to modify the electronic properties, significantly enhancing the electrical conductivity. Nitrogen doping, in particular, introduces electron-rich sites, improving the conductivity of SWCNTs.

- Example: Nitrogen-doped SWCNTs have been used in supercapacitors, where their enhanced conductivity improves the charge/discharge performance.

- Metallic Doping: Introducing metal atoms (e.g., lithium, potassium) into the structure of SWCNTs can create additional charge carriers, leading to enhanced electrical conductivity. These doping methods are particularly useful in applications like batteries and energy storage devices.

- Example: Potassium-doped SWCNTs have shown improved electrochemical performance in lithium-ion batteries.

1.2. Chemical Functionalization

- Oxidation: Functionalizing SWCNTs by introducing oxygen-containing groups (e.g., hydroxyl, carboxyl) can significantly improve their dispersion in solvents and polymers. However, excessive oxidation can damage the nanotube structure, so it is crucial to control the oxidation degree.

- Example: Carboxylated SWCNTs are used in composites, where they improve electrical conductivity by facilitating better interaction with polymer matrices.

1.3. Reduction Techniques

- Reduction of Defects: Various reduction methods, such as thermal annealing or chemical reduction, are employed to restore the conductivity of oxidized SWCNTs. This process can reduce the oxygen-containing groups, thereby enhancing the nanotube’s electronic properties.

- Example: Chemical reduction methods using reducing agents like hydrazine can restore the electrical properties of SWCNTs, making them more suitable for conductive films or electrodes.

2. Thermal Conductivity Enhancement

SWCNTs exhibit extraordinary thermal conductivity (up to 3,000 W/m·K), but this property is often degraded in bulk materials or composites. Optimizing their thermal conductivity is essential for applications in heat management, electronics, and energy systems.

2.1. Doping for Thermal Conductivity

- Boron Doping: Boron doping is one of the most effective methods to enhance thermal conductivity, as boron atoms can alter the lattice vibrations in the SWCNT structure, optimizing thermal transport.

- Example: Boron-doped SWCNTs have shown superior thermal conductivity in polymer composites used for heat dissipation applications in electronic devices.

- Sulfur Doping: Incorporating sulfur into the nanotube structure can increase the vibrational modes and improve phonon transport, which enhances the overall thermal conductivity.

- Example: Sulfur-doped SWCNTs are used in thermoelectric materials, where their improved thermal conductivity aids in the efficient conversion of heat into electrical energy.

2.2. Defect Engineering

- Defect Control: A key challenge in SWCNTs is the presence of defects, which can scatter phonons and reduce thermal conductivity. Researchers are developing methods to control and minimize defects during synthesis, leading to more efficient thermal transport.

- Example: By optimizing the synthesis process to reduce defects, such as the use of precise growth temperatures in chemical vapor deposition (CVD), the thermal conductivity of SWCNTs can be significantly improved.

2.3. Polymer Composites for Thermal Conductivity

- SWCNT/Polymer Blends: The combination of SWCNTs with polymers can result in composites with enhanced thermal properties. Functionalizing SWCNTs with polymers improves the dispersion and interaction between nanotubes, leading to better heat conduction.

- Example: SWCNT/epoxy composites are widely studied for thermal management applications, offering superior heat dissipation in electronic devices and automotive components.

3. Mechanical Property Enhancement

SWCNTs are known for their exceptional mechanical properties, such as high tensile strength (up to 100 GPa) and stiffness. However, these properties can be degraded due to poor dispersion, defects, and entanglements, limiting their use in large-scale applications. Various techniques have been developed to optimize these properties.

3.1. Doping for Mechanical Strength

- Boron and Nitrogen Doping: Doping with boron or nitrogen not only enhances electrical and thermal properties but also improves the mechanical strength of SWCNTs. The introduction of these heteroatoms can enhance the bonding between nanotubes and the surrounding matrix in composites, leading to increased tensile strength and elasticity.

- Example: Nitrogen-doped SWCNTs have been incorporated into polymer matrices to form lightweight composites with significantly enhanced mechanical strength, making them ideal for aerospace and automotive applications.

3.2. Structural Defect Repair

- Annealing: High-temperature annealing can repair structural defects such as vacancies and Stone-Wales defects, which can weaken the mechanical strength of SWCNTs. By optimizing annealing conditions, it is possible to restore the structural integrity of SWCNTs.

- Example: Annealed SWCNTs exhibit improved mechanical properties, including enhanced fracture toughness and higher tensile strength, suitable for use in composite materials for load-bearing applications.

3.3. Surface Functionalization for Improved Dispersion

- Polymer Coating: Functionalizing SWCNTs with polymer chains (e.g., polystyrene or polyethylene glycol) enhances their dispersion in solvents and matrices, improving their alignment and distribution in composite materials. Better dispersion leads to improved mechanical performance.

- Example: SWCNTs functionalized with polyethylene glycol (PEG) are used in composite materials for automotive and aerospace applications, where improved dispersion results in stronger, more durable composites.

3.4. Multi-Walled Carbon Nanotube (MWCNT) and SWCNT Hybrid Composites

- Hybrid Systems: Combining SWCNTs with multi-walled carbon nanotubes (MWCNTs) can synergistically enhance the mechanical properties of composites. The MWCNTs provide bulk strength, while the SWCNTs contribute to the overall performance with their exceptional properties.

- Example: Hybrid SWCNT/MWCNT composites are used in high-performance coatings and structural components that require both flexibility and high strength.

4. Improved Dispersion Methods

The dispersion of SWCNTs is a critical factor in maximizing their performance in various applications. Poor dispersion can lead to agglomeration, which diminishes the effectiveness of SWCNTs, particularly in composites and coatings.

4.1. Surfactant-Assisted Dispersion

- Surfactants: The use of surfactants such as cetyltrimethylammonium bromide (CTAB) or polyvinyl alcohol (PVA) can significantly improve the dispersion of SWCNTs in aqueous and organic solvents. This method helps to reduce agglomeration and improve the interaction between SWCNTs and the matrix in composite materials.

- Example: Surfactant-assisted dispersion is widely used in the preparation of conductive films, where a uniform distribution of SWCNTs ensures improved electrical conductivity.

4.2. Plasma Treatment

- Plasma Functionalization: Plasma treatment involves the use of ionized gases to modify the surface of SWCNTs, introducing functional groups that enhance their dispersion in various solvents. Plasma-treated SWCNTs exhibit improved compatibility with polymer matrices, leading to better composite properties.

- Example: Plasma-functionalized SWCNTs are used in the production of high-performance coatings and adhesives, where good dispersion is essential for achieving optimal mechanical and thermal properties.

4.3. Solvent-Assisted Dispersion

- Solvent Systems: Using specific solvents (e.g., N-methyl-pyrrolidone, NMP) along with ultrasonication or high-speed shearing techniques can break up SWCNT agglomerates and improve their dispersion. This method is often used in the preparation of conductive inks and coatings.

- Example: Solvent-assisted dispersion is critical in the preparation of SWCNT-based conductive pastes for electronics and sensors.

5. Conclusion

The optimization of single-walled carbon nanotubes (SWCNTs) continues to evolve with advancements in doping, purification, and dispersion techniques. These improvements enhance their performance in key areas such as electrical conductivity, thermal conductivity, and mechanical strength, expanding their potential for use in a wide range of applications, including energy storage, composites, sensors, and electronics.

As research progresses, more efficient and cost-effective methods for producing and functionalizing SWCNTs will likely make them more accessible for large-scale industrial applications, paving the way for their widespread adoption in fields ranging from aerospace to electronics to biomedical engineering. The continued development of SWCNT performance optimization holds immense promise for the next generation of high-performance materials.