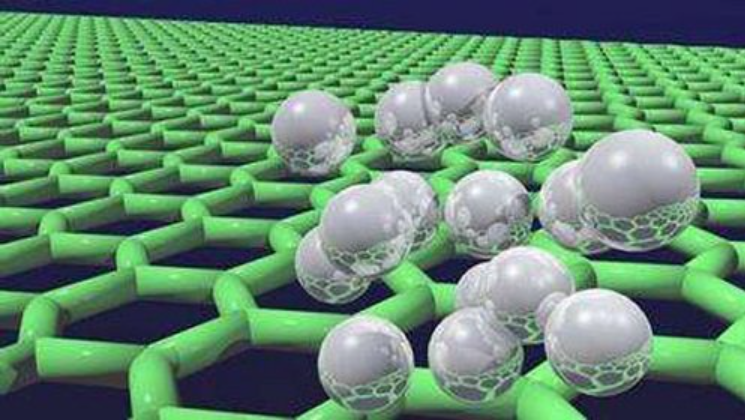

Metal or metal oxide nanoparticles supported on graphene are a class of advanced materials that combine the unique properties of graphene with the catalytic, electronic, and optical properties of metals and metal oxides. This synergistic combination has opened new opportunities in fields ranging from catalysis to energy storage and environmental protection. In this article, we delve into the synthesis methods, advantages, and applications of these hybrid materials.

1. Introduction to Metal/Metal Oxide-Decorated Graphene

Metal/metal oxide-decorated graphene is a hybrid material created by anchoring nanoscale metal or metal oxide particles onto the surface of graphene. These nanoparticles benefit from graphene’s large surface area, excellent conductivity, and stability, while the graphene matrix enhances the dispersion and performance of the nanoparticles.

Common metals used include platinum, gold, and silver, while metal oxides like titanium dioxide (TiO₂), zinc oxide (ZnO), and manganese dioxide (MnO₂) are frequently employed due to their exceptional properties.

2. Synthesis Methods

The fabrication of metal/metal oxide-decorated graphene involves techniques that enable uniform dispersion and strong adhesion of nanoparticles onto the graphene surface. Below are some commonly used methods:

2.1 Solution-Based Methods

Solution-based methods are among the most popular approaches due to their simplicity and scalability.

- Hydrothermal or Solvothermal Method: Graphene oxide (GO) or reduced graphene oxide (rGO) is mixed with a solution containing metal precursors, which are reduced to nanoparticles under high temperature and pressure.

- Co-Precipitation Method: Metal salts are co-precipitated with graphene in the presence of a reducing agent to form the hybrid material.

- Advantages: Solution-based methods allow for the fine-tuning of particle size and distribution through controlled reaction conditions.

2.2 Chemical Vapor Deposition (CVD)

CVD is a high-precision method that involves depositing metal or metal oxide nanoparticles onto graphene.

- Process: A metal precursor is vaporized and reacts with a carbon source in a high-temperature environment, forming metal/metal oxide nanoparticles on graphene.

- Advantages: CVD provides excellent control over the thickness and morphology of the deposited nanoparticles.

2.3 Electrodeposition

In electrodeposition, metal ions in a solution are reduced and deposited onto a graphene-coated electrode through an applied electric field.

- Advantages: This method is particularly useful for creating highly uniform and adherent nanoparticle coatings on graphene.

2.4 Microwave-Assisted Synthesis

Microwave heating can rapidly produce metal/metal oxide-decorated graphene by reducing metal precursors in a graphene dispersion.

- Advantages: Microwave-assisted methods offer rapid reaction times and uniform heating, making them suitable for large-scale production.

3. Advantages of Metal/Metal Oxide-Decorated Graphene

The integration of metals or metal oxides with graphene imparts several advantages:

3.1 High Catalytic Activity

The large surface area of graphene enhances the dispersion of metal/metal oxide nanoparticles, exposing more active sites for catalytic reactions.

3.2 Enhanced Conductivity and Thermal Properties

The combination of metallic particles and graphene improves both electrical and thermal conductivity, making these hybrids ideal for electronic and energy applications.

3.3 Stability and Durability

Graphene’s mechanical strength and chemical stability protect the nanoparticles, preventing agglomeration and degradation.

3.4 Tunable Properties

The material’s properties can be tailored by selecting specific metals or metal oxides and optimizing their loading, size, and distribution.

4. Applications of Metal/Metal Oxide-Decorated Graphene

The synergistic properties of these hybrid materials enable a wide range of industrial and research applications:

4.1 Catalysis

Metal/metal oxide-decorated graphene is extensively used as a catalyst in various chemical and electrochemical reactions.

- Automotive Catalysts: Platinum-decorated graphene is used in catalytic converters to reduce harmful emissions from vehicles.

- Hydrogen Generation: Metal oxides like TiO₂ on graphene enhance photocatalytic hydrogen production from water splitting.

- Chemical Reactions: These materials are used in oxidation and reduction reactions, including CO₂ reduction and organic synthesis.

4.2 Energy Storage

These hybrid materials improve the performance of batteries and supercapacitors:

- Lithium-Ion Batteries (LIBs): Metal oxide nanoparticles like MnO₂ on graphene enhance energy density and cycling stability by facilitating fast ion diffusion.

- Supercapacitors: Hybrid materials exhibit high capacitance and rapid charge-discharge capabilities due to their excellent conductivity and active surface area.

4.3 Sensing Applications

Graphene-based hybrids are highly sensitive to environmental changes, making them suitable for sensor technologies:

- Gas Sensors: Metal-decorated graphene can detect gases such as NO₂, CO, and H₂ with high sensitivity and selectivity.

- Biosensors: These materials are used in medical diagnostics for detecting biomolecules like glucose or DNA.

4.4 Environmental Protection

Metal/metal oxide-decorated graphene finds applications in addressing environmental challenges:

- Pollutant Degradation: TiO₂-decorated graphene is used in photocatalytic systems to degrade organic pollutants in water.

- Heavy Metal Removal: The hybrid material can adsorb heavy metals like arsenic and lead from wastewater.

- Air Purification: These hybrids are employed in filters to capture and degrade airborne contaminants.

5. Case Studies and Industrial Applications

Case Study 1: Platinum-Decorated Graphene for Fuel Cells

Platinum nanoparticles supported on graphene are widely used as catalysts in proton exchange membrane fuel cells (PEMFCs). This hybrid material exhibits high catalytic efficiency and durability, significantly improving fuel cell performance.

Case Study 2: TiO₂-Graphene in Photocatalytic Water Treatment

Titanium dioxide-decorated graphene has been employed in large-scale water treatment plants to break down organic contaminants and disinfect water under UV or visible light.

Case Study 3: MnO₂-Graphene for Supercapacitors

Manganese dioxide nanoparticles anchored on graphene have been integrated into commercial supercapacitors, providing high energy density and excellent cycling stability.

6. Challenges and Future Directions

Despite their advantages, several challenges remain:

- Scalability: Large-scale synthesis of uniformly decorated graphene materials is still challenging.

- Cost: Precious metals like platinum increase material costs, necessitating research into alternative materials.

- Optimization: Further research is needed to optimize the interaction between graphene and metal/metal oxide nanoparticles for specific applications.

Future research will likely focus on:

- Developing cost-effective and scalable synthesis methods.

- Exploring alternative, earth-abundant metals and oxides.

- Integrating these hybrids into next-generation technologies, such as wearable electronics and renewable energy systems.

7. Conclusion

Metal/metal oxide-decorated graphene represents a powerful class of hybrid materials with exceptional properties and wide-ranging applications. From catalysis and energy storage to sensing and environmental protection, these materials are driving advancements across multiple industries.

As research continues, the potential of these hybrids in emerging technologies such as hydrogen energy, smart sensors, and sustainable environmental solutions will undoubtedly expand, positioning them as key enablers of a cleaner, more efficient future.