Metal/Metal Oxide-Decorated Graphene: Revolutionizing Advanced Material Applications

Graphene, often termed the “wonder material,” is celebrated for its exceptional electrical, thermal, and mechanical properties. When combined with metal or metal oxide nanoparticles, graphene transforms into a hybrid material with a vast array of applications. These composite materials capitalize on the synergistic interaction between graphene and nanoparticles, leading to superior catalytic, sensing, and energy storage capabilities.

In this article, we explore the synthesis methods, advantages, and applications of metal/metal oxide-decorated graphene, highlighting its transformative potential across industries.

1. Understanding Metal/Metal Oxide-Decorated Graphene

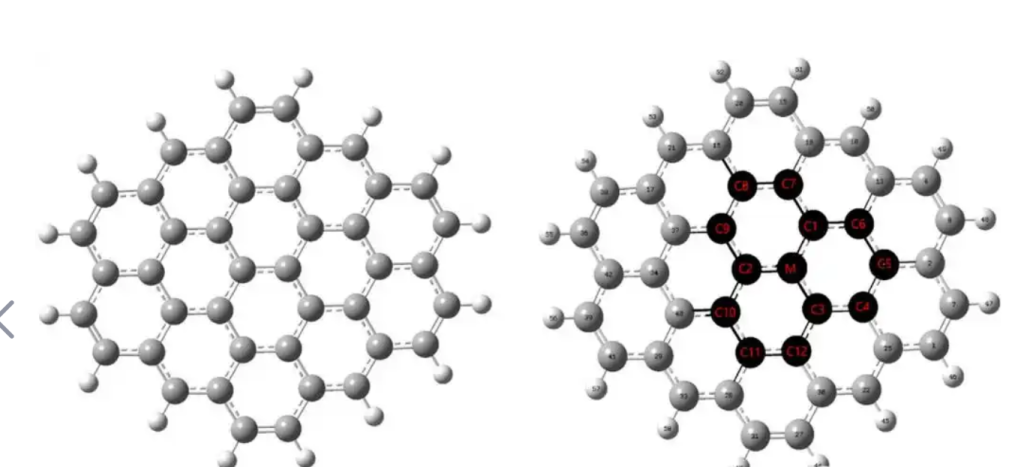

Metal/metal oxide-decorated graphene involves the integration of nanoscale particles of metals (e.g., platinum, gold, silver) or metal oxides (e.g., TiO₂, ZnO, MnO₂) onto the surface of graphene. This integration exploits graphene’s high surface area and conductivity, creating materials that excel in catalysis, energy applications, and environmental remediation.

These hybrids bring together:

- The high catalytic activity of metals/metal oxides.

- Graphene’s excellent conductivity and large surface area.

2. Synthesis Methods for Metal/Metal Oxide-Decorated Graphene

Producing high-quality metal/metal oxide-decorated graphene requires precise techniques to ensure uniform dispersion and strong adhesion of nanoparticles to graphene. Key synthesis methods include:

2.1 Solution-Based Methods

Solution-based methods dominate due to their simplicity and adaptability to diverse applications.

- Hydrothermal/Solvothermal Methods: A graphene oxide (GO) or reduced graphene oxide (rGO) dispersion is mixed with metal precursors and subjected to high temperature and pressure. The precursors reduce to form nanoparticles on graphene.

- Co-Precipitation: Metal salts co-precipitate with graphene in the presence of reducing agents.

Advantages:

- Enables control over nanoparticle size and distribution.

- Simple, cost-effective, and scalable.

2.2 Chemical Vapor Deposition (CVD)

CVD is a high-precision technique used to deposit metal/metal oxide nanoparticles on graphene under controlled conditions.

Advantages:

- Produces uniform, well-adhered nanoparticle coatings.

- Allows precise control of layer thickness and particle morphology.

2.3 Electrodeposition

Electrodeposition involves reducing metal ions from a solution onto a graphene-coated electrode under an applied electric field.

Advantages:

- Produces highly uniform and tightly bonded nanoparticle layers.

- Compatible with various metals and metal oxides.

2.4 Microwave-Assisted Synthesis

Microwave heating rapidly reduces metal precursors in graphene dispersions, forming nanoparticle-decorated graphene.

Advantages:

- Fast and energy-efficient.

- Suitable for large-scale production.

3. Advantages of Metal/Metal Oxide-Decorated Graphene

3.1 High Catalytic Activity

The combination of graphene’s high surface area and the active sites of metal/metal oxide nanoparticles enhances catalytic performance, particularly in reactions requiring large active surface areas.

3.2 Superior Conductivity and Thermal Properties

Graphene improves the electrical and thermal conductivity of metal/metal oxide hybrids, making them ideal for high-performance electronics and energy storage applications.

3.3 Improved Stability and Durability

Graphene protects metal/metal oxide nanoparticles from agglomeration and oxidation, enhancing the hybrid material’s lifespan and stability.

3.4 Versatile Functionalization

These hybrids can be tailored for specific applications by altering nanoparticle type, size, and loading.

4. Application Industries

4.1 Catalysis

Metal/metal oxide-decorated graphene is an ideal catalyst for various chemical and electrochemical reactions:

- Automotive Emission Control: Platinum or palladium-decorated graphene is widely used in catalytic converters to reduce toxic vehicle emissions.

- Hydrogen Generation: TiO₂-graphene hybrids enhance the efficiency of photocatalytic water splitting, a critical reaction for clean hydrogen production.

- Industrial Chemical Processes: These materials are employed in oxidation and reduction reactions, including CO₂ reduction to valuable hydrocarbons.

4.2 Energy Storage

Energy storage is one of the most transformative applications of metal/metal oxide-decorated graphene.

- Lithium-Ion Batteries (LIBs): MnO₂-decorated graphene improves battery performance by enhancing ion diffusion, capacity retention, and cycle stability.

- Supercapacitors: Hybrid materials exhibit high energy density and rapid charge-discharge capabilities, suitable for portable electronics and electric vehicles.

- Fuel Cells: Graphene-supported platinum nanoparticles act as efficient catalysts in fuel cells, reducing material costs while boosting performance.

4.3 Environmental Protection

These hybrids play a critical role in environmental remediation and sustainability efforts:

- Water Treatment: TiO₂-graphene composites effectively degrade organic pollutants and adsorb heavy metals, ensuring clean water.

- Air Pollution Control: Catalytic hybrids capture and neutralize harmful gases, including NOx and CO, improving air quality.

- Soil Remediation: These materials aid in breaking down toxic organic compounds in contaminated soils.

4.4 Sensing Technologies

Graphene-based hybrids excel in sensing applications due to their high sensitivity and conductivity.

- Gas Sensors: Metal-decorated graphene can detect low concentrations of gases like NO₂, CO, and H₂, making it invaluable for industrial safety and environmental monitoring.

- Biosensors: These materials are used to detect biomolecules such as glucose or DNA, revolutionizing medical diagnostics.

- Chemical Sensors: Metal oxide nanoparticles like ZnO enhance the sensitivity and selectivity of graphene for detecting chemicals in industrial processes.

5. Real-World Case Studies

5.1 Platinum-Graphene Catalysts for Fuel Cells

Fuel cell performance is often limited by catalyst degradation. Platinum nanoparticles on graphene not only reduce material costs but also enhance durability, enabling long-term operation in vehicles and stationary power systems.

5.2 MnO₂-Graphene for High-Performance Supercapacitors

A leading manufacturer integrated MnO₂-graphene composites into its supercapacitors, achieving energy densities comparable to batteries while retaining fast charge-discharge rates. These devices are now used in electric buses and grid storage systems.

5.3 TiO₂-Graphene in Industrial Water Treatment

A water treatment facility utilized TiO₂-graphene hybrids to remove organic pollutants and disinfect municipal water supplies. The hybrid material’s photocatalytic efficiency enabled cost-effective and environmentally friendly operations.

6. Challenges and Future Directions

Challenges:

- Scalability: Large-scale synthesis methods need further refinement to ensure uniformity and cost-efficiency.

- Cost of Precious Metals: Alternative materials are needed to reduce dependency on expensive metals like platinum.

- Material Stability: Although graphene stabilizes nanoparticles, long-term stability under harsh conditions remains a concern.

Future Directions:

- Development of Alternative Metals: Research is focusing on earth-abundant metals like nickel and iron for cost-effective hybrids.

- Optimization for Specific Applications: Tailoring the material properties for targeted industries, such as renewable energy and environmental protection.

- Integration into Next-Generation Technologies: Applications in wearable electronics, smart sensors, and quantum computing are areas of active exploration.

7. Conclusion

Metal/metal oxide-decorated graphene hybrids represent a groundbreaking advancement in material science. Their unique combination of properties has positioned them at the forefront of catalysis, energy storage, sensing, and environmental remediation.

As research progresses, the adoption of these materials in emerging technologies will accelerate, fostering innovations that address global challenges such as energy sustainability and environmental conservation.

By exploring scalable production methods and cost-effective materials, we can unlock the full potential of metal/metal oxide-decorated graphene, paving the way for a cleaner and more efficient future.