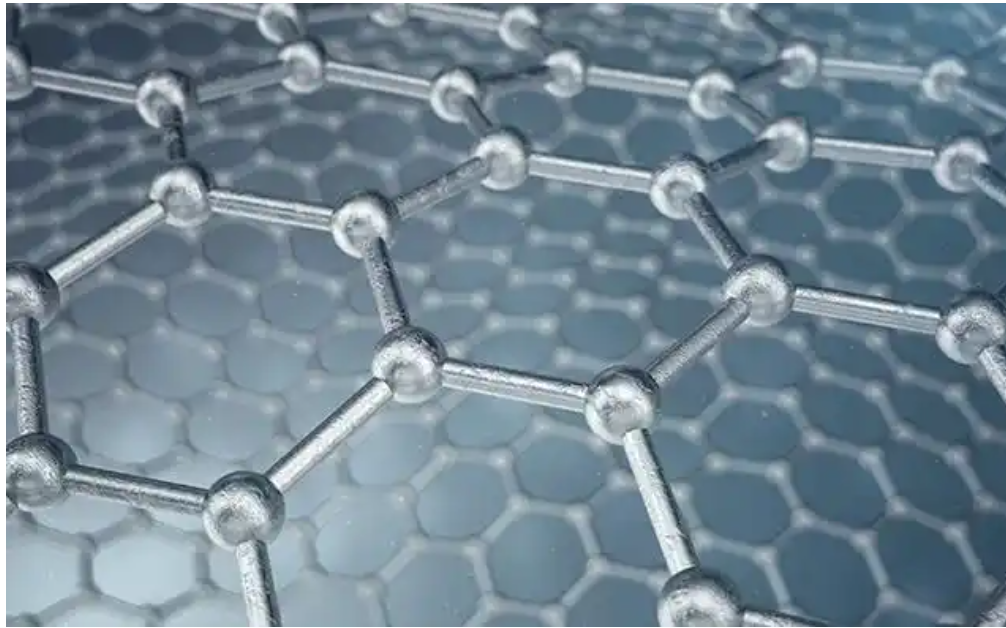

Graphene in Coatings: Key Functions and Applications

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has revolutionized many industries due to its exceptional properties. When incorporated into coatings, graphene imparts unique functionalities that significantly enhance the performance and durability of the coated materials. Below, we explore the major functions and applications of graphene in coatings, with real-world examples for each function.

1. Corrosion Resistance

Graphene’s remarkable barrier properties make it highly effective in preventing corrosion. The graphene sheets create a strong, impermeable barrier that prevents moisture, oxygen, and other corrosive elements from penetrating the surface of the coated material. This is particularly useful for protecting metals, such as steel and aluminum, in harsh environments like marine, industrial, and offshore applications.

Example:

- Marine Industry: Graphene-based coatings are used on ships and offshore platforms to extend their lifespan by preventing rust and corrosion in saltwater environments. These coatings offer superior protection compared to traditional anti-corrosion paints, providing an eco-friendly and more durable alternative.

2. Antibacterial and Antifungal Properties

Graphene oxide (GO) and reduced graphene oxide (rGO) possess inherent antibacterial and antifungal properties. This makes graphene-infused coatings ideal for applications where hygiene and cleanliness are critical, such as in medical, food, and pharmaceutical industries. The sharp edges of graphene sheets can disrupt microbial membranes, leading to the destruction of bacteria and fungi.

Example:

- Healthcare and Pharmaceuticals: Hospitals and clinics use graphene-based coatings on surfaces to reduce the spread of harmful bacteria. Graphene coatings are applied to door handles, medical devices, and walls, creating antimicrobial surfaces that help maintain sterile environments and prevent hospital-acquired infections (HAIs).

3. Electrical Conductivity

Graphene is an excellent conductor of electricity, making graphene-based coatings highly valuable for applications that require conductive properties. When incorporated into coatings, graphene can enhance the conductivity of surfaces without compromising the coating’s appearance or flexibility. This is particularly important in the electronics, automotive, and aerospace industries.

Example:

- Electronics: Graphene coatings are used in the production of printed circuit boards (PCBs) and other electronic components. They provide superior conductivity, reduce resistance, and improve the overall efficiency of electronic devices, ensuring they perform optimally for longer periods.

- Automotive Industry: Graphene-based coatings are applied to electric vehicle batteries and components to improve conductivity and heat dissipation, enhancing the performance and longevity of these parts.

4. Thermal Conductivity

Graphene has an exceptionally high thermal conductivity, making it an ideal material for applications that require efficient heat management. When added to coatings, graphene can significantly improve the heat dissipation properties of materials, preventing overheating and ensuring the longevity and reliability of electronic components, machinery, and infrastructure.

Example:

- Electronics and LED Lighting: Graphene coatings are used in heat sinks for LED lights, computers, and smartphones. The ability of graphene to conduct heat away from sensitive components helps to prevent thermal damage, thus increasing the lifespan of the devices.

- Aerospace: Graphene coatings are applied to aircraft parts to manage heat generated during flight. These coatings help dissipate heat from engine parts and electronic systems, ensuring optimal performance and preventing overheating.

5. UV Protection

Graphene’s ability to absorb UV radiation makes it an excellent material for coatings that provide UV protection. Coatings that incorporate graphene can prevent damage to surfaces caused by prolonged exposure to sunlight, including fading, cracking, and degradation of the material beneath. This is particularly valuable in outdoor applications where UV exposure is a concern.

Example:

- Outdoor Furniture and Coatings: Graphene-based coatings are applied to outdoor furniture, tents, and equipment to protect them from UV damage. The coating helps maintain the integrity and appearance of these products, extending their usability and reducing the need for frequent replacements.

- Solar Panels: Graphene coatings are used to protect solar panels from UV degradation, thus enhancing their efficiency and extending their service life.

6. Wear and Scratch Resistance

The strength and durability of graphene make it an ideal material for improving the wear resistance of coatings. Graphene-infused coatings can resist scratching, abrasion, and general wear-and-tear, ensuring that surfaces remain intact and functional over a longer period. This is beneficial for applications in high-traffic areas or industrial settings where surfaces are subjected to constant physical stress.

Example:

- Automotive Industry: Graphene coatings are applied to vehicle exteriors to enhance scratch resistance. The coatings protect car paint from minor abrasions caused by stones, keys, or other environmental factors, helping to maintain the vehicle’s appearance and value.

- Industrial Equipment: Graphene coatings are used on machinery and tools in factories and warehouses to reduce wear and extend the lifespan of expensive equipment. These coatings improve the resistance of surfaces to mechanical damage, reducing maintenance costs.

7. Self-healing Properties

Graphene coatings can be engineered to have self-healing capabilities. This means that minor cracks and scratches that appear on the surface can automatically repair themselves over time, thanks to the unique properties of graphene. Self-healing coatings are particularly useful in harsh environments where traditional coatings would quickly degrade.

Example:

- Aerospace and Automotive: Graphene-based self-healing coatings are used on aircraft and vehicles to repair minor surface damage caused by impacts or friction. This helps maintain the structural integrity and appearance of the vehicles while reducing the need for frequent repairs and touch-ups.

Conclusion

Graphene’s multifunctional properties make it an incredibly versatile material for use in coatings. By enhancing performance in areas such as corrosion resistance, antibacterial protection, conductivity, heat management, and scratch resistance, graphene coatings are becoming a key component in various industries, including automotive, electronics, healthcare, and construction. As research and development continue, the potential applications of graphene in coatings will expand, offering even more advanced solutions for modern technological challenges.