Recycling and Reuse of Waste Carbon Nanotubes: A Sustainability Perspective in Green Manufacturing

Introduction

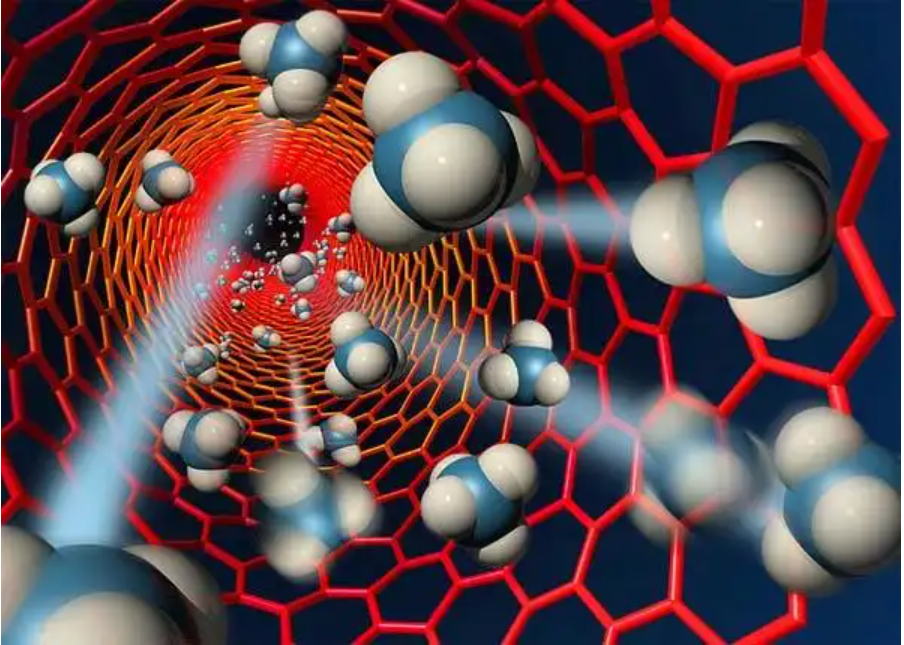

As the production and application of carbon nanotubes (CNTs) continue to expand across various industries, addressing the disposal and recycling of waste CNTs has become a critical sustainability challenge. This article explores innovative recycling and reuse technologies, highlighting their role in promoting green manufacturing and reducing environmental impact.

Why Recycle Carbon Nanotubes?

1. Environmental Impact

- Waste CNTs, if improperly disposed of, can persist in the environment due to their chemical stability and potential toxicity.

- Reducing landfill contributions aligns with global sustainability goals.

2. Resource Optimization

- CNTs are produced from high-value raw materials using energy-intensive processes.

- Recycling ensures efficient use of resources and cost savings.

3. Regulatory Compliance

- Stricter environmental regulations necessitate sustainable practices for CNT lifecycle management.

Current Challenges in CNT Recycling

1. Material Integrity

- Preserving the structural and functional properties of CNTs during recycling is challenging.

2. Contamination Issues

- Waste CNTs are often mixed with other materials, complicating the separation process.

3. Economic Feasibility

- Recycling technologies must be cost-effective to compete with virgin CNT production.

Technologies for CNT Recycling and Reuse

1. Physical Recovery Methods

Mechanical Separation

- Description: Physical methods such as filtration or centrifugation to separate CNTs from composites or solutions.

- Applications: Recovery of CNTs from polymer matrices.

- Advantages: Simple and low-cost; minimal chemical use.

- Limitations: Limited effectiveness for highly integrated systems.

Thermal Processing

- Description: Heat treatment to remove non-CNT components.

- Applications: Reuse of CNTs in applications where minor structural degradation is acceptable.

- Advantages: Effective for bulk recovery.

- Limitations: Risk of CNT oxidation or damage.

2. Chemical Recycling Techniques

Solvent Extraction

- Description: Selective dissolution of matrices to liberate CNTs.

- Applications: Recovery from polymer composites and coatings.

- Advantages: High recovery rates; preserves CNT properties.

- Limitations: Solvent handling and disposal concerns.

Catalytic Decomposition

- Description: Catalysts break down non-CNT materials, leaving CNTs intact.

- Applications: Separation from organic matrices.

- Advantages: High specificity; potential for scalability.

- Limitations: Requires precise control to avoid CNT damage.

3. Refunctionalization and Upcycling

Surface Refunctionalization

- Description: Chemical modification to restore or enhance CNT properties.

- Applications: Reuse in electronics, sensors, and energy storage devices.

- Advantages: Extends CNT usability; creates value-added products.

- Limitations: Involves complex and cost-intensive processes.

Carbon Recovery

- Description: CNTs are converted into other carbon-based materials such as graphene or activated carbon.

- Applications: Use in filtration systems, catalysis, or energy storage.

- Advantages: Broadens application scope; aligns with circular economy principles.

- Limitations: Transformation processes may alter desired properties.

Case Studies and Applications

1. Energy Storage

- Recovered CNTs integrated into lithium-ion battery anodes demonstrated comparable performance to virgin CNTs.

- Impact: Reduced material costs by 30% in pilot studies.

2. Environmental Remediation

- Waste CNTs upcycled into adsorbents for removing heavy metals from water.

- Impact: Enhanced adsorption efficiency and reduced water treatment costs.

3. Composite Materials

- Recycled CNTs incorporated into reinforced polymers for automotive applications.

- Impact: Improved mechanical properties while reducing production waste.

Future Directions in CNT Recycling

- Integration of Automation

- Real-time monitoring and AI-driven optimization of recycling processes.

- Development of Green Processes

- Use of eco-friendly solvents and catalysts to minimize environmental impact.

- Hybrid Recycling Methods

- Combining physical, chemical, and thermal techniques for maximum recovery efficiency.

- Lifecycle Assessment

- Comprehensive analysis of CNT recycling’s environmental, economic, and social impacts to guide sustainable practices.

Conclusion

The recycling and reuse of carbon nanotubes represent a pivotal step toward sustainable manufacturing. By leveraging innovative technologies and adopting circular economy principles, the industry can reduce its environmental footprint while maximizing the value of CNT materials. Continued advancements in this field promise to transform CNT recycling from a challenge into an opportunity for green innovation.