Graphene-Carbon Nanotube (CNT) Composites: A Game-Changer in Advanced Materials

The integration of graphene and carbon nanotubes (CNTs) into a single composite material represents a breakthrough in the field of nanotechnology. These composites leverage the unique properties of both graphene and CNTs, offering unparalleled performance in conductivity, mechanical strength, and thermal management.

This article explores the synthesis methods, key advantages, and diverse applications of graphene-CNT composites, emphasizing their transformative potential across industries like electronics, energy, and advanced materials.

1. What Are Graphene-CNT Composites?

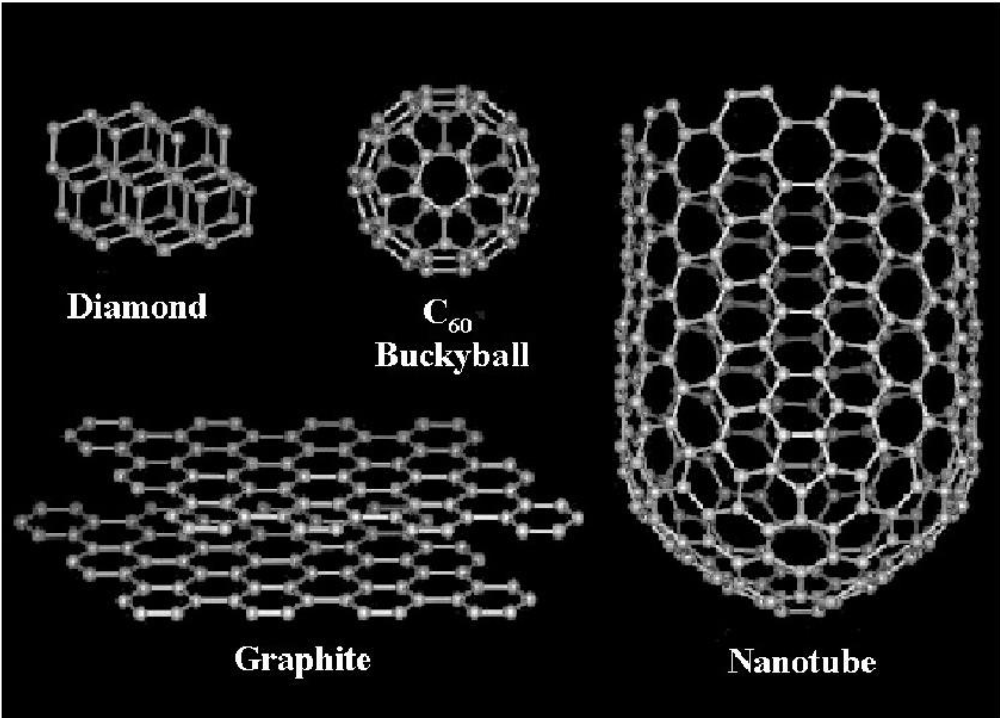

Graphene-CNT composites are hybrid materials that combine the two most prominent carbon-based nanomaterials: graphene, a single layer of carbon atoms arranged in a hexagonal lattice, and carbon nanotubes, cylindrical tubes of carbon atoms. Together, they synergize their properties to form high-performance materials that outperform their individual components.

2. Synthesis Methods for Graphene-CNT Composites

The fabrication of graphene-CNT composites involves several advanced techniques that ensure uniform dispersion and strong bonding between the two nanomaterials.

2.1 Physical Mixing

This method involves mechanically mixing graphene and CNTs in a solution to form a homogeneous composite.

- Process:

- Graphene and CNTs are dispersed in a solvent using ultrasonication.

- The mixture is filtered, dried, and pressed into a composite material.

Advantages:

- Simple and cost-effective.

- Suitable for scalable production.

2.2 Chemical Reduction

This method combines graphene oxide (GO) and CNTs, followed by chemical reduction to form the composite.

- Process:

- GO is mixed with CNTs in a solution.

- A reducing agent like hydrazine or ascorbic acid is added to restore graphene’s conductivity and bond it with CNTs.

Advantages:

- Improves electrical conductivity.

- Produces composites with functionalized surfaces for specific applications.

2.3 Chemical Vapor Deposition (CVD)

CVD is a sophisticated technique for directly growing CNTs on graphene or vice versa.

- Process:

- Graphene or CNTs are placed in a high-temperature furnace.

- Hydrocarbon gases decompose, depositing carbon atoms to form CNTs on graphene or graphene layers on CNTs.

Advantages:

- Produces highly ordered composites.

- Ensures strong interfacial bonding and structural integrity.

3. Advantages of Graphene-CNT Composites

Graphene-CNT composites offer several benefits over standalone graphene or CNTs, making them highly attractive for advanced applications.

3.1 Enhanced Electrical Conductivity

The combination of graphene’s high electron mobility and CNTs’ excellent conductivity results in composites with superior electrical properties.

3.2 Improved Mechanical Strength

Graphene provides high tensile strength, while CNTs add flexibility and structural stability, resulting in composites with exceptional mechanical durability.

3.3 Superior Thermal Conductivity

The hybrid structure efficiently transfers heat, making these composites ideal for thermal management in electronics and energy systems.

3.4 Better Dispersion and Stability

Graphene-CNT composites address the challenge of CNT aggregation, ensuring uniform dispersion and stable structures.

4. Applications of Graphene-CNT Composites

4.1 Electronics and Electrical Engineering

Graphene-CNT composites are revolutionizing the electronics industry by enabling the development of lightweight, high-performance materials.

- Conductive Films: Used in flexible displays, touchscreens, and electromagnetic interference (EMI) shielding.

- Sensors: Enhanced sensitivity and faster response times for gas, pressure, and strain sensors.

- Electronic Components: Used in transistors and interconnects for high-speed electronics.

Case Study:

A research team developed graphene-CNT composite films for wearable electronics, achieving superior flexibility and conductivity, ideal for next-generation devices.

4.2 Energy Storage and Conversion

The high surface area, excellent conductivity, and mechanical stability of graphene-CNT composites make them ideal for energy storage and conversion technologies.

- Batteries: Used as electrodes in lithium-ion batteries to improve charge capacity, cycle stability, and energy density.

- Supercapacitors: Enables rapid charge-discharge cycles with high energy storage efficiency.

- Fuel Cells: Enhances the performance of catalyst supports in hydrogen fuel cells.

Case Study:

Graphene-CNT composite electrodes were incorporated into supercapacitors, resulting in a threefold increase in energy density and improved cycle life compared to conventional materials.

4.3 Advanced Composite Materials

Graphene-CNT composites are widely used to enhance the properties of traditional materials such as plastics, rubbers, and metals.

- Structural Reinforcement: Added to polymers to improve mechanical strength, thermal stability, and electrical conductivity.

- Lightweight Materials: Used in aerospace and automotive industries to create lightweight yet strong components.

- Anti-Static Materials: Prevents static electricity buildup in packaging and electronic components.

Case Study:

Aerospace manufacturers adopted graphene-CNT composites in aircraft structural components, reducing weight by 20% while increasing strength and thermal performance.

5. Challenges and Future Directions

5.1 Challenges

- Cost and Scalability: High production costs and challenges in large-scale synthesis limit widespread adoption.

- Interface Engineering: Achieving strong interfacial bonding between graphene and CNTs remains complex.

- Quality Control: Ensuring uniformity and consistency in composites is challenging.

5.2 Future Directions

- Eco-Friendly Methods: Development of green synthesis techniques to reduce environmental impact.

- Hybrid Composites: Combining graphene-CNT composites with other materials like polymers or metals for tailored properties.

- Emerging Applications: Exploring new uses in quantum computing, biomedical devices, and advanced thermal systems.

6. Conclusion

Graphene-CNT composites are reshaping the landscape of advanced materials, offering unmatched performance in conductivity, strength, and thermal management. With applications spanning electronics, energy, and structural materials, these composites are set to drive innovation across multiple industries.

While challenges remain in cost and scalability, ongoing research and development are paving the way for more sustainable and accessible production methods. The future of graphene-CNT composites holds immense potential, promising transformative impacts on technology and society.