Graphene’s Corrosion Resistance and Its Application in Coatings

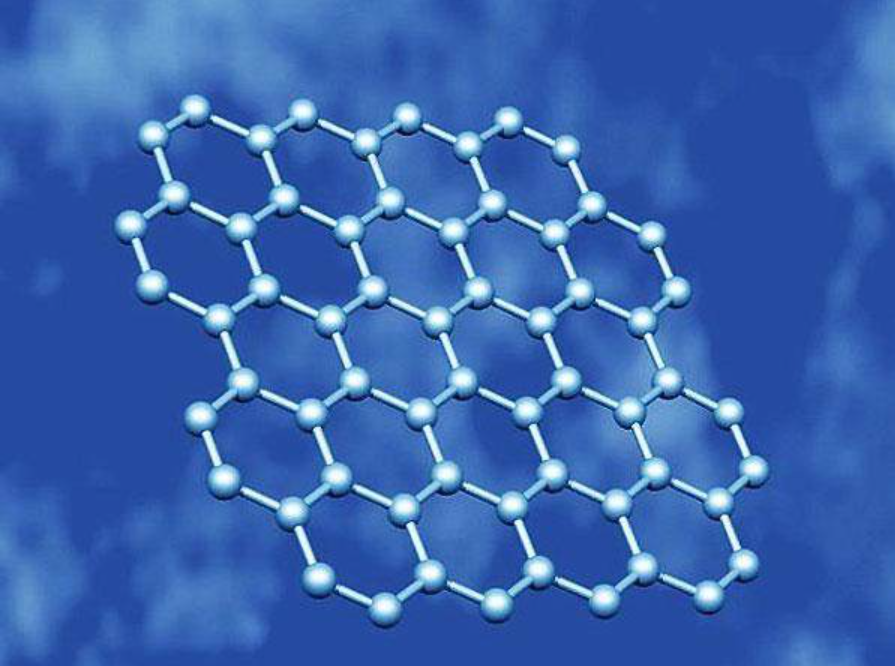

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has become a breakthrough material in corrosion protection due to its unique properties. Its high surface area, impermeability, and chemical stability make it highly effective in preventing corrosion, particularly in harsh environmental conditions. When integrated into coatings, graphene can significantly enhance the protective performance against corrosion in various industries, such as marine, automotive, aerospace, and infrastructure.

Key Properties of Graphene that Contribute to Corrosion Resistance

-

Impermeability

Graphene is a two-dimensional material that is nearly impermeable to gases and liquids. This characteristic prevents moisture, oxygen, and corrosive substances from reaching the underlying metal surfaces, which are typically responsible for initiating the corrosion process.- Example: Graphene-based coatings on steel surfaces form an impervious barrier, blocking the penetration of moisture and oxygen that can trigger rust formation.

-

High Surface Area

With a specific surface area of around 2630 m²/g, graphene provides a large area for interaction with other components in the coating, improving adhesion and providing greater surface protection.- Example: Graphene coatings applied to aluminum alloys have shown significant improvement in corrosion resistance by enhancing the adhesion between the metal surface and the coating.

-

Chemical Stability

Graphene is chemically stable and resistant to most reactive chemicals. This stability prevents degradation of the coating itself when exposed to aggressive environments, such as acid rains, saltwater, or industrial pollutants.- Example: In marine environments, graphene-based coatings protect ship hulls from the corrosive effects of seawater, significantly reducing maintenance costs.

-

Electrochemical Properties

Graphene’s ability to conduct electrons also makes it beneficial in preventing electrochemical corrosion. By dispersing graphene into a coating, it enhances the conductivity and acts as a protective layer that reduces the risk of galvanic corrosion between metal components.- Example: Graphene-infused primers are used in pipelines to prevent the electrochemical reactions that typically lead to corrosion under electrical currents.

-

Antioxidant Properties

Graphene oxide (GO), a derivative of graphene, exhibits antioxidant properties, providing extra protection against oxidation. When incorporated into coatings, GO can react with free radicals, effectively reducing the chances of oxidation.- Example: Adding graphene oxide to coatings used in automotive and aerospace industries helps protect metal parts from oxidation and degradation caused by environmental exposure.

Applications of Graphene in Corrosion Protection Coatings

1. Marine Industry

- Use Case: Graphene-based coatings are applied to ship hulls, marine pipelines, and offshore oil rigs to protect against seawater corrosion, which is a major cause of structural degradation.

- Example: A graphene-based antifouling coating was developed for ships, effectively preventing the growth of marine organisms and reducing corrosion rates, thus lowering maintenance costs.

2. Automotive Industry

- Use Case: Graphene coatings are used to protect automotive parts, such as chassis, exhaust systems, and fuel tanks, from rust and corrosion caused by road salts, water, and environmental pollutants.

- Example: A graphene-based coating was applied to car body panels, showing a reduction in corrosion rates by 40% compared to conventional coatings, even under harsh environmental conditions.

3. Infrastructure and Construction

- Use Case: Graphene coatings are used to protect steel, concrete, and other materials in bridges, buildings, and tunnels from corrosion due to moisture, chloride exposure, and other environmental factors.

- Example: Graphene-enhanced coatings on reinforced concrete bridges in coastal areas have shown significant improvements in corrosion resistance, reducing the need for costly repairs and extending service life.

4. Oil and Gas Industry

- Use Case: Pipelines and storage tanks are coated with graphene to prevent internal and external corrosion caused by chemical exposure, moisture, and the corrosive effects of oil and gas transport.

- Example: Graphene-based coatings on offshore oil rigs have demonstrated the ability to withstand harsh offshore environments, significantly reducing maintenance costs and downtime.

5. Aerospace Industry

- Use Case: In aerospace applications, graphene coatings are used to protect aircraft components from corrosion caused by moisture, UV radiation, and extreme temperature variations.

- Example: Graphene coatings applied to aircraft fuselages have shown improved resistance to corrosion, especially in environments with high humidity and salt exposure.

Advantages of Graphene in Corrosion Protection Coatings

-

Longer Durability

The high impermeability and stability of graphene enhance the longevity of coatings, reducing the need for frequent re-coating and repairs. -

Eco-friendly

Graphene-based coatings can replace toxic anti-corrosive agents such as chromates, providing a more environmentally friendly alternative. -

Enhanced Performance in Harsh Environments

Graphene’s chemical stability makes it ideal for protecting materials in extreme environments, including marine, industrial, and aerospace settings. -

Cost-Effective

While the initial cost of graphene may be high, the increased lifespan and reduced maintenance needs of graphene-coated materials result in cost savings in the long term.

Challenges and Future Prospects

Challenges:

- Production Scalability: While graphene production has scaled up in recent years, manufacturing large quantities of high-quality graphene for industrial applications still faces challenges.

- Cost: Although the cost of graphene is decreasing, it remains a significant barrier for widespread commercial adoption.

- Coating Formulation: Achieving a uniform dispersion of graphene within coatings and ensuring consistent quality remains a technical challenge.

Future Prospects:

- Hybrid Coatings: Combining graphene with other nanomaterials (such as nanotubes, nanowires, or carbon black) to create multifunctional coatings with superior properties, including enhanced corrosion resistance, mechanical strength, and thermal stability.

- Smart Coatings: Future graphene-based coatings may be developed with self-healing capabilities, allowing them to repair themselves when damaged, further extending their protective properties.

Conclusion

Graphene’s unique properties—impermeability, high surface area, chemical stability, and excellent conductivity—make it an exceptional material for corrosion-resistant coatings. The use of graphene in protective coatings is revolutionizing industries such as marine, automotive, aerospace, and infrastructure by offering more durable, efficient, and eco-friendly solutions. As graphene production methods improve and costs decrease, its use in corrosion protection coatings will likely expand, providing significant economic and environmental benefits.