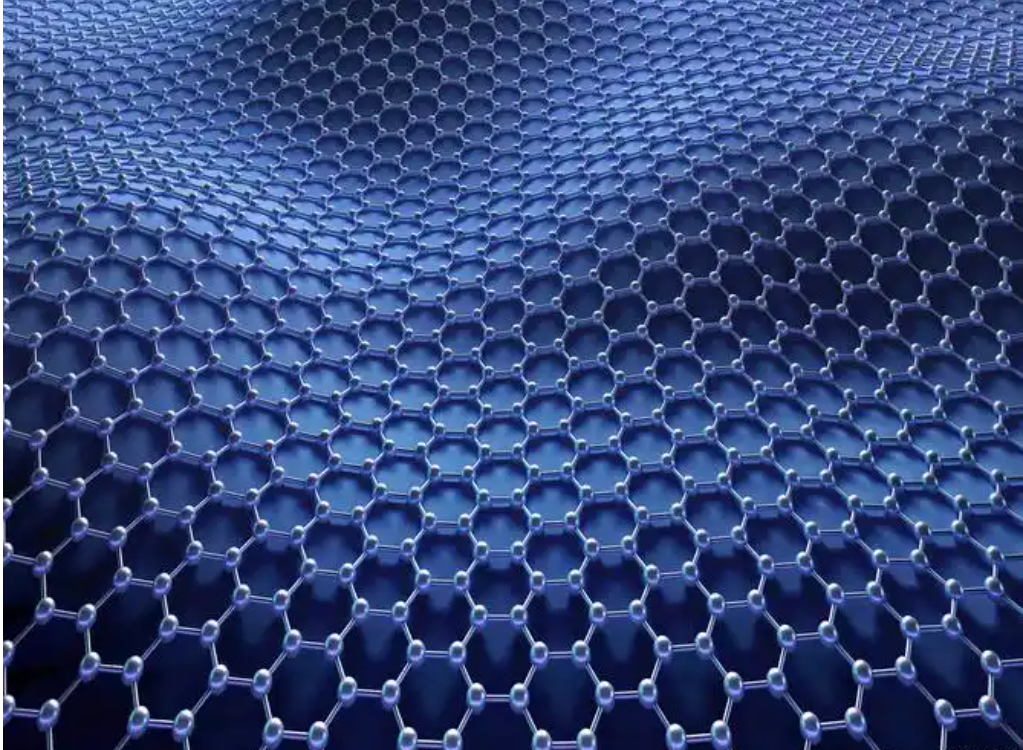

Graphene Coatings for UV Resistance and Aging Resistance

Graphene, with its remarkable properties, has proven to be an effective material for improving the UV resistance and aging resistance of coatings. These qualities are especially important for materials exposed to outdoor environments, where prolonged exposure to ultraviolet (UV) radiation and environmental stress can degrade the performance and appearance of the material. By incorporating graphene into coatings, it is possible to enhance the durability of surfaces and prolong their lifespan.

1. UV Resistance of Graphene Coatings

UV radiation, a major component of sunlight, can break down many materials, particularly polymers, leading to discoloration, brittleness, and loss of mechanical properties. Graphene coatings provide effective protection against UV damage due to their high stability and the ability to absorb or reflect UV radiation.

Key Properties of Graphene for UV Protection:

-

High UV Absorption and Scattering

Graphene can absorb a significant amount of UV radiation due to its wide bandgap and ability to interact with a broad spectrum of light. This property prevents the UV rays from reaching the underlying material, which helps protect it from degradation.- Example: Graphene coatings on polymer-based materials can block UV radiation, reducing the risk of photo-oxidation and preventing the material from becoming brittle or discolored.

-

Stability Under UV Exposure

Graphene is chemically stable even when exposed to UV radiation, unlike many organic materials that degrade over time. This stability helps extend the lifespan of the coating and the material it protects.- Example: In outdoor applications such as building facades or automotive parts, graphene coatings maintain their protective properties and appearance even under prolonged UV exposure.

-

Enhanced UV Reflectivity

Graphene’s high surface area and its ability to reflect UV rays further enhance the protective performance of coatings. This reflection prevents UV light from penetrating deeper into the material.- Example: Solar panel coatings with graphene reflect a significant portion of UV radiation, preventing the degradation of photovoltaic cells and improving their efficiency over time.

Applications of Graphene in UV-Protective Coatings:

-

Automotive Coatings: Graphene-based coatings applied to car exteriors can protect against UV-induced fading and cracking, ensuring that the paint retains its color and gloss for longer periods.

- Example: A graphene-based clear coat on a car can prevent the paint from fading and maintain its gloss even after exposure to direct sunlight for extended periods.

-

Construction and Infrastructure: Graphene coatings are applied to outdoor structures, including bridges, rooftops, and walls, to prevent UV degradation of materials like concrete, steel, and polymer composites.

- Example: Buildings in regions with high UV radiation benefit from graphene-enhanced coatings that preserve the appearance and integrity of the materials, even in harsh climates.

-

Textiles and Outdoor Fabrics: Graphene-infused coatings are used to protect outdoor fabrics from UV damage, helping them maintain their color and strength.

- Example: Outdoor furniture fabrics coated with graphene resist fading and degradation from UV rays, extending their service life and aesthetic appeal.

2. Aging Resistance of Graphene Coatings

Aging refers to the gradual deterioration of materials over time due to environmental exposure, chemical reactions, and physical wear. In coatings, aging can manifest as discoloration, loss of gloss, cracking, or chalking. Graphene coatings enhance the aging resistance of materials by providing a protective layer that mitigates these effects.

Key Properties of Graphene for Aging Resistance:

-

Improved Mechanical Strength and Flexibility

Graphene’s exceptional mechanical properties, including high tensile strength and elasticity, allow coatings to withstand stress and prevent cracking or peeling due to aging. Graphene enhances the overall flexibility and toughness of the coating, which helps it maintain its integrity over time.- Example: Graphene coatings on outdoor plastic products, like garden furniture, help resist cracks and deformation caused by long-term exposure to sun, rain, and temperature fluctuations.

-

Resistance to Oxidation and Degradation

Graphene provides protection against environmental factors such as moisture, chemicals, and temperature variations, which contribute to the oxidation and degradation of traditional coatings. By preventing the infiltration of these agents, graphene slows down the aging process of materials.- Example: In marine environments, graphene coatings on metal surfaces protect against rust and corrosion caused by saltwater exposure, significantly extending the lifespan of ships, pipelines, and offshore structures.

-

Anti-Chalking Properties

Many coatings, particularly those exposed to UV radiation, suffer from chalking, which is the formation of a powdery surface due to the degradation of the binder. Graphene’s robust structure resists chalking and helps preserve the coating’s appearance and performance.- Example: Graphene-based coatings on exterior paints and coatings for buildings show reduced chalking and retain their original color and texture even after years of exposure.

-

Enhanced Barrier Properties

The dense, impermeable nature of graphene helps to create a strong barrier against moisture, oxygen, and other environmental factors that can contribute to aging. This barrier helps to maintain the integrity of the coating and the material it protects.- Example: Graphene coatings applied to pipelines or storage tanks prevent the ingress of water or chemicals, which would otherwise lead to material degradation over time.

Applications of Graphene in Aging-Resistant Coatings:

-

Marine Industry: Graphene coatings are used on ships, offshore platforms, and marine equipment to prevent corrosion, rust, and other signs of aging due to prolonged exposure to seawater and harsh environmental conditions.

- Example: A graphene-based anti-corrosion coating on a boat’s hull reduces the risk of corrosion and enhances the coating’s durability against saltwater, algae, and other environmental factors.

-

Electronics and Electrical Components: Graphene coatings are applied to electronic devices, circuit boards, and electrical connectors to prevent aging due to oxidation, humidity, and temperature fluctuations.

- Example: In electronic devices, graphene coatings protect sensitive components from environmental stress, improving the longevity of the devices.

-

Building Materials: Graphene coatings on building materials such as concrete, steel, and bricks help prevent the deterioration of these materials due to aging, exposure to chemicals, and temperature cycles.

- Example: Concrete structures in regions with harsh weather conditions benefit from graphene-based coatings that prevent cracking, spalling, and degradation due to freeze-thaw cycles.

Optimization Methods for UV and Aging Resistance in Graphene Coatings

To further enhance the UV and aging resistance of graphene coatings, several optimization techniques can be applied:

-

Graphene Composite Coatings: Combining graphene with other UV-absorbing or aging-resistant materials, such as UV stabilizers or antioxidants, can further improve the performance of the coating. This creates a synergistic effect, where the combined properties offer superior protection.

- Example: Graphene composite coatings that incorporate UV stabilizers and anti-aging additives help reduce the effects of UV radiation and environmental degradation.

-

Functionalization of Graphene: Functionalizing graphene with specific chemical groups (such as hydroxyl or carboxyl groups) can improve its dispersion in the coating and enhance its interaction with other components, leading to better UV resistance and longer-lasting protection.

- Example: Functionalized graphene coatings are used to increase the adhesion of the coating to substrates, resulting in improved performance and longer protection against aging.

-

Layered Coating Systems: Applying multiple layers of graphene-based coatings, each designed for specific functions (e.g., UV protection, barrier properties, and mechanical strength), can enhance the overall durability and resistance to aging.

- Example: A multi-layer graphene coating on a building facade provides UV protection on the outer layer, while the inner layers focus on anti-corrosion and aging resistance.

Conclusion

Graphene coatings significantly improve the UV resistance and aging resistance of materials, making them highly valuable in industries such as construction, automotive, electronics, and marine applications. With their ability to block UV radiation, reduce aging effects, prevent oxidation, and maintain mechanical integrity, graphene-based coatings are ideal for extending the lifespan and performance of various products exposed to harsh environmental conditions. By optimizing graphene coatings through functionalization, composites, and multi-layer systems, their effectiveness can be further enhanced, offering sustainable and durable solutions for modern industries.