A Guide to Carbon Nanotubes (CNTs) and Their Applications

What Are Carbon Nanotubes?

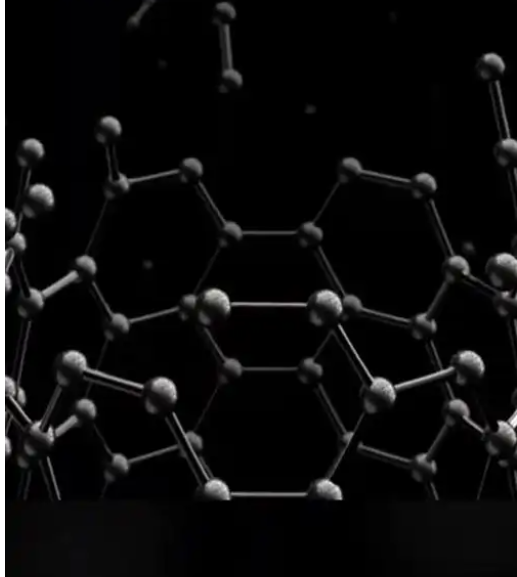

Carbon nanotubes (CNTs) are cylindrical molecules made up of carbon atoms arranged in a hexagonal lattice. They are known for their extraordinary mechanical, electrical, and thermal properties, making them highly useful in a variety of applications, from electronics to materials science. CNTs are categorized into two main types: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs), each with unique characteristics and uses.

Types of Carbon Nanotubes

Carbon nanotubes come in different forms, each with specific properties suitable for various applications. Here’s a breakdown:

-

Single-Walled Carbon Nanotubes (SWCNTs)

These CNTs consist of a single sheet of carbon atoms rolled into a tube. They are ideal for applications requiring high strength and conductivity, such as in nanoelectronics, sensors, and energy storage devices. -

Multi-Walled Carbon Nanotubes (MWCNTs)

MWCNTs consist of several concentric tubes of carbon atoms. They are typically stronger and more robust than SWCNTs, making them ideal for reinforcing composite materials, batteries, and fuel cells. -

Functionalized Carbon Nanotubes

By attaching various chemical groups to CNTs, scientists can enhance their properties and make them more compatible with specific applications, such as drug delivery, water filtration, and catalysis.

Key Properties of Carbon Nanotubes

-

Mechanical Strength

Carbon nanotubes exhibit outstanding tensile strength, often exceeding that of steel. This makes them useful in creating lightweight, strong materials for aerospace, automotive, and construction industries. -

Electrical Conductivity

CNTs are excellent conductors of electricity, which makes them ideal for use in electronic devices, conductive coatings, and energy storage systems like batteries and supercapacitors. -

Thermal Conductivity

With their high thermal conductivity, CNTs can efficiently dissipate heat, which is crucial for applications in electronics and heat-resistant materials. -

Chemical Stability

CNTs are highly resistant to corrosion and chemical degradation, making them suitable for harsh environments, including chemical reactors and sensors.

Applications of Carbon Nanotubes

-

Electronics and Nanoelectronics

CNTs are used in the development of faster and more efficient electronic components, such as transistors, capacitors, and display screens. Their small size and excellent conductivity allow for the miniaturization of electronic devices. -

Energy Storage and Conversion

CNTs are widely used in batteries, fuel cells, and supercapacitors due to their excellent conductivity and ability to store energy efficiently. They are particularly valuable in the development of next-generation energy storage technologies. -

Composite Materials

Adding CNTs to materials like plastics, metals, and ceramics can greatly enhance their mechanical properties. They are used to make lighter and stronger materials for use in automotive parts, aircraft components, and construction. -

Medical Applications

CNTs have potential in drug delivery, biosensors, and tissue engineering due to their small size, biocompatibility, and ability to interact with biological systems at the molecular level.

How Carbon Nanotubes Are Manufactured

The production of carbon nanotubes involves several methods, including:

-

Chemical Vapor Deposition (CVD)

This is the most common method for producing CNTs, where carbon-containing gases are decomposed at high temperatures to form nanotubes on a substrate. -

Arc Discharge

In this process, carbon is vaporized in a high-voltage arc, leading to the formation of CNTs. This method is typically used for producing large quantities of CNTs but is less precise than CVD. -

Laser Ablation

A laser is used to vaporize carbon in a high-temperature chamber, producing carbon nanotubes. This method is often used for producing high-purity CNTs.

Maintenance of Carbon Nanotubes for Optimal Performance

Proper handling and maintenance are crucial to maintaining the quality and effectiveness of CNTs in various applications:

-

Storage

CNTs should be stored in a dry, clean environment to prevent contamination. Ideally, they should be kept in sealed containers to avoid exposure to moisture and air, which can affect their properties. -

Cleaning

If CNTs are used in sensitive applications, such as electronics or medical devices, it’s important to clean them to remove any impurities or surface contaminants that could affect their performance. -

Handling

Carbon nanotubes are sensitive to mechanical damage. Proper handling procedures should be followed to avoid breakage or alteration of their structure, which could affect their strength and conductivity.

Common Mistakes to Avoid with Carbon Nanotubes

-

Inadequate Dispersion

CNTs need to be evenly dispersed in a matrix (such as a polymer or metal) to ensure optimal performance. Poor dispersion can lead to weak spots and reduced effectiveness of the material. -

Overloading CNTs

While CNTs are strong, overloading them beyond their capacity can lead to structural failure. It’s important to ensure that they are used within the limits of their mechanical properties. -

Improper Functionalization

Functionalizing CNTs requires careful attention to the chemical processes involved. Using the wrong functionalization techniques or reagents can damage the nanotubes and reduce their effectiveness for the intended application.

FAQs

What are the main types of carbon nanotubes?

The main types are single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs).

What are carbon nanotubes used for?

Carbon nanotubes are used in a variety of applications, including electronics, energy storage, composite materials, and medical devices.

How are carbon nanotubes manufactured?

The most common methods for manufacturing carbon nanotubes are chemical vapor deposition (CVD), arc discharge, and laser ablation.