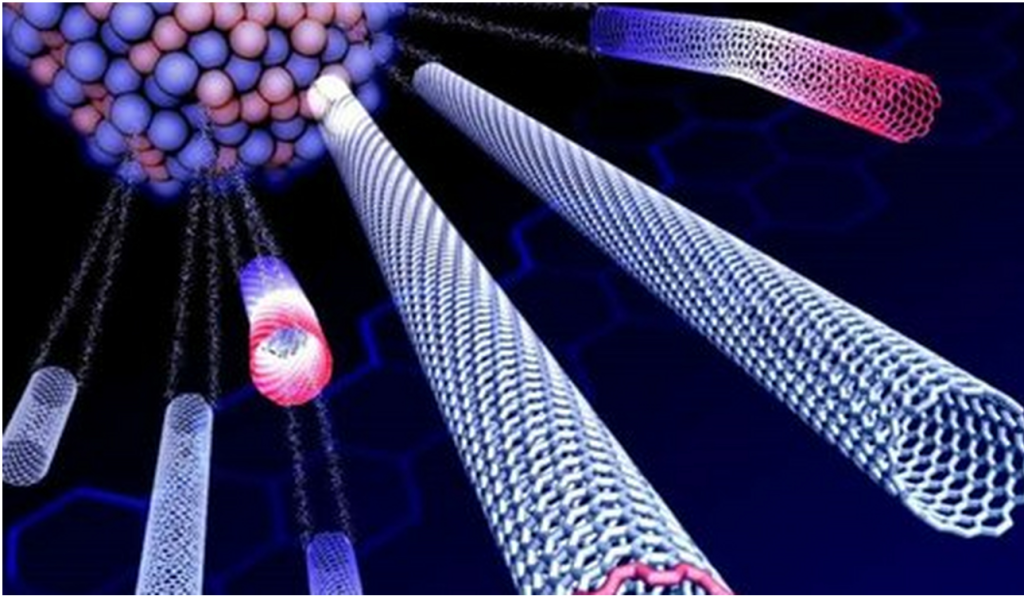

The Development and Potential of Bio-Based Carbon Nanotubes: An Eco-Friendly Approach from Raw Materials to Manufacturing

Introduction

As industries move towards sustainability, the demand for eco-friendly nanomaterials is rising. Bio-based carbon nanotubes (CNTs) represent an innovative advancement in the field of nanotechnology, offering an environmentally sustainable alternative to traditional CNT production methods. By utilizing renewable biomass sources instead of fossil-based precursors, bio-based CNTs can reduce carbon footprints while maintaining the superior properties required for high-performance applications.

This article explores the potential of bio-based CNTs, covering raw material selection, sustainable manufacturing processes, and key applications that contribute to the green economy.

1. Challenges in Conventional Carbon Nanotube Production

Traditional CNT synthesis, primarily through chemical vapor deposition (CVD), arc discharge, and laser ablation, relies on fossil-derived feedstocks such as hydrocarbons (e.g., methane, ethylene, acetylene). While these methods produce high-quality CNTs, they come with environmental concerns:

- High Carbon Emissions: Hydrocarbon-based CVD generates significant CO₂ emissions, contributing to global warming.

- Energy-Intensive Processes: Conventional methods require high temperatures (600–1200°C), leading to excessive energy consumption.

- Toxic Byproducts: Certain catalysts and reaction gases can produce hazardous byproducts, posing health and environmental risks.

To address these challenges, researchers are shifting towards bio-based precursors to develop CNTs with a lower environmental footprint.

2. Bio-Based Carbon Nanotubes: Sustainable Raw Materials

Bio-based CNTs are synthesized using natural and renewable carbon sources, including:

2.1 Biomass-Derived Precursors

- Lignin: A byproduct of the paper and biofuel industry, lignin is a rich carbon source for CNT synthesis.

- Cellulose: Found in plants and agricultural waste, cellulose-derived CNTs offer a cost-effective and abundant alternative.

- Algae and Microorganisms: Certain algae species produce carbon-rich compounds that can be converted into CNTs.

2.2 Waste Materials as Carbon Sources

- Food Waste: Banana peels, coffee grounds, and coconut shells contain carbon structures suitable for CNT production.

- Plastic Waste: Bio-refining techniques enable the transformation of biodegradable plastics into CNTs, reducing landfill waste.

Using these natural precursors reduces reliance on fossil fuels while promoting a circular economy.

3. Eco-Friendly Manufacturing of Bio-Based CNTs

Sustainable CNT synthesis methods are being developed to replace traditional high-energy processes. Some key green manufacturing techniques include:

3.1 Low-Temperature Chemical Vapor Deposition (CVD)

- Modified CVD techniques allow for biomass-derived carbon sources to produce CNTs at lower temperatures (400–800°C instead of 1000+°C).

- This significantly reduces energy consumption and carbon emissions.

3.2 Plasma-Based Synthesis

- Plasma-assisted processes break down bio-based precursors into nanotube structures without requiring harsh chemicals.

- This method minimizes environmental impact while maintaining high yield and purity.

3.3 Hydrothermal Carbonization (HTC)

- HTC enables the conversion of biomass waste into CNTs using water-based reactions at moderate temperatures (~200–300°C).

- It offers a low-energy alternative with minimal CO₂ emissions.

4. Advantages of Bio-Based CNTs

By leveraging renewable carbon sources and green synthesis methods, bio-based CNTs offer multiple advantages:

- Lower Carbon Footprint: Reduces reliance on petroleum-based feedstocks, cutting CO₂ emissions by up to 50%.

- Sustainable Resource Utilization: Converts agricultural and industrial waste into high-value nanomaterials.

- Biodegradable Potential: Some bio-CNT composites exhibit improved biodegradability, reducing long-term environmental impact.

- Cost-Effectiveness: Utilizing waste materials and biomass lowers raw material costs, making CNT production more economical.

5. Key Applications of Bio-Based CNTs

5.1 Energy Storage: Sustainable Batteries & Supercapacitors

- Bio-CNTs enhance the performance of lithium-ion batteries and supercapacitors, providing higher conductivity and energy density.

- Researchers are exploring bio-derived CNT electrodes to replace traditional fossil-based materials.

5.2 Green Construction & Cement Additives

- Bio-CNTs improve concrete strength, durability, and water resistance, supporting sustainable infrastructure.

- Their nanostructured reinforcement reduces cement usage, lowering carbon emissions in construction.

5.3 Environmental Remediation

- Bio-based CNTs act as effective adsorbents for heavy metals, pollutants, and CO₂ capture, supporting clean water and air purification technologies.

5.4 Flexible & Wearable Electronics

- CNT-based bioelectronics offer sustainable alternatives for flexible sensors, conductive textiles, and biomedical devices.

- Bio-derived CNT inks are used in printed electronics for next-generation smart materials.

6. Challenges and Future Outlook

Despite their potential, bio-based CNTs face several challenges:

- Scalability: Large-scale production still requires optimization to match the efficiency of conventional methods.

- Purity & Quality Control: Ensuring high structural integrity and uniformity is crucial for industrial applications.

- Market Adoption: Industries need further validation of bio-CNT performance, reliability, and cost benefits.

Future Trends

- Advancements in Bio-CVD Technologies: Continuous research is improving low-energy CNT growth techniques.

- Integration with Circular Economy Strategies: Industries are incorporating bio-CNTs into waste-to-nanomaterial initiatives.

- Government & Industry Support: Increased investment in green nanotechnology policies will accelerate commercialization.

Conclusion

Bio-based carbon nanotubes are paving the way for a sustainable nanotechnology revolution, providing an eco-friendly alternative to traditional CNTs. By utilizing renewable resources, low-carbon manufacturing methods, and innovative applications, bio-CNTs contribute to clean energy, green construction, and environmental remediation. As research advances and production scales up, bio-based CNTs will play a crucial role in building a greener, more sustainable future.