Weight Reduction and Strength Optimization of Carbon Nanotube-Reinforced Vehicle Structures

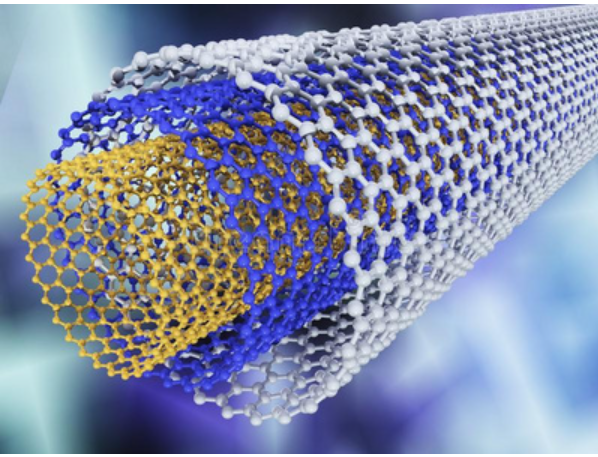

With increasing demands for lightweight, high-strength, and fuel-efficient vehicles, carbon nanotubes (CNTs) have emerged as a revolutionary material for automotive structural components. Their exceptional mechanical strength, low density, and superior toughness make them ideal for reinforcing composites in car bodies, significantly reducing weight while enhancing durability and crash resistance.

1. The Need for Lightweight and Strong Vehicle Structures

✔ Challenges in Automotive Design:

-

Reducing vehicle weight without compromising strength.

-

Enhancing fuel efficiency and electric vehicle (EV) range.

-

Improving safety and impact resistance.

-

Meeting strict emission regulations through lightweight materials.

✔ Why CNTs?

-

200× stronger than steel, yet lighter than aluminum.

-

Excellent energy absorption, crucial for crash safety.

-

Superior fatigue and wear resistance, improving durability.

-

Multi-functional properties, including electrical conductivity for smart materials.

2. Weight Reduction with CNT-Reinforced Composites

CNT-Enhanced Polymer Composites

✔ Traditional materials: Steel, aluminum, carbon fiber-reinforced plastics (CFRP).

✔ CNT-enhanced alternatives:

-

CNT-reinforced polymer composites offer 50% weight reduction compared to steel.

-

CNT-reinforced carbon fiber composites improve strength without adding weight.

-

Injection-molded CNT-polymer composites reduce weight in interior and structural panels.

✔ Applications:

-

Body panels, bumpers, and chassis (e.g., CNT-reinforced CFRP).

-

Lightweight doors, roofs, and underbodies.

-

Electric vehicle battery enclosures, reducing weight and improving thermal stability.

➡ Example: Tesla and BMW are already using carbon fiber composites to reduce vehicle weight; CNTs can further enhance these materials.

3. Strength and Durability Optimization

Superior Impact Resistance and Crash Safety

✔ Challenge:

Traditional lightweight materials, such as aluminum, lack sufficient impact absorption.

✔ CNT Solution:

-

CNTs distribute impact forces more effectively than standard materials.

-

CNT-reinforced composites increase tensile strength and energy absorption.

-

CNTs prevent microcracks from propagating, improving crashworthiness.

✔ Benefit:

-

Increased passenger safety in the event of collisions.

-

Reduced structural damage, lowering repair costs.

Fatigue and Corrosion Resistance

✔ Challenge:

-

Traditional metals suffer from fatigue failure and corrosion over time.

-

Aluminum and CFRP weaken under long-term stress cycles.

✔ CNT Solution:

-

Self-healing properties: CNT networks can redistribute stress, reducing fatigue damage.

-

Corrosion resistance: CNT coatings and composites prevent oxidation and chemical degradation.

✔ Benefit:

-

Longer lifespan of structural components.

-

Lower maintenance costs for lightweight vehicles.

4. Multifunctional Benefits for Next-Generation Vehicles

✔ Electrically Conductive Body Panels

-

Enables built-in sensors for real-time monitoring.

-

Eliminates the need for additional wiring in vehicle structures.

✔ Enhanced Thermal Management

-

CNTs improve heat dissipation in battery enclosures for EVs.

-

Prevents thermal expansion and contraction, improving composite durability.

✔ Noise and Vibration Reduction

-

CNT-reinforced composites dampen vibrations, improving passenger comfort.

5. Future of CNT-Based Vehicle Structures

✔ Next Steps for the Automotive Industry:

-

Mass production of CNT composites at lower costs.

-

Integration with 3D printing for customized vehicle components.

-

Hybrid CNT-metal structures combining lightweight metals with CNT coatings.

✔ Potential Market Impact:

-

Electric vehicles benefit from reduced weight, increasing battery efficiency.

-

Autonomous vehicles integrate smart CNT-based materials for self-monitoring structures.

-

Sustainability: Lighter cars lead to lower emissions and energy consumption.

Conclusion

Carbon nanotube-enhanced materials represent a game-changing innovation in automotive engineering. By significantly reducing weight, improving strength, and enhancing durability, CNTs pave the way for safer, more efficient, and longer-lasting vehicles. As production costs decrease and technology advances, CNT composites will become a standard in next-generation automotive design.