Applications of Graphene and Carbon Nanotubes in Smart Manufacturing and AI

Graphene in Thermal Management for Smart Manufacturing

Graphene’s extraordinary thermal conductivity makes it an ideal material for managing heat in high-performance electronics and smart manufacturing systems. Devices operating under high loads, such as AI processors, often suffer from overheating. Incorporating graphene into thermal interface materials and coatings can significantly enhance heat dissipation, protect sensitive components, and improve overall system reliability. Graphene composites and films are already being explored in cooling systems for smartphones, laptops, and industrial machinery. This opens new opportunities in markets demanding high efficiency and durability.

Graphene and Carbon Nanotubes in AI Hardware

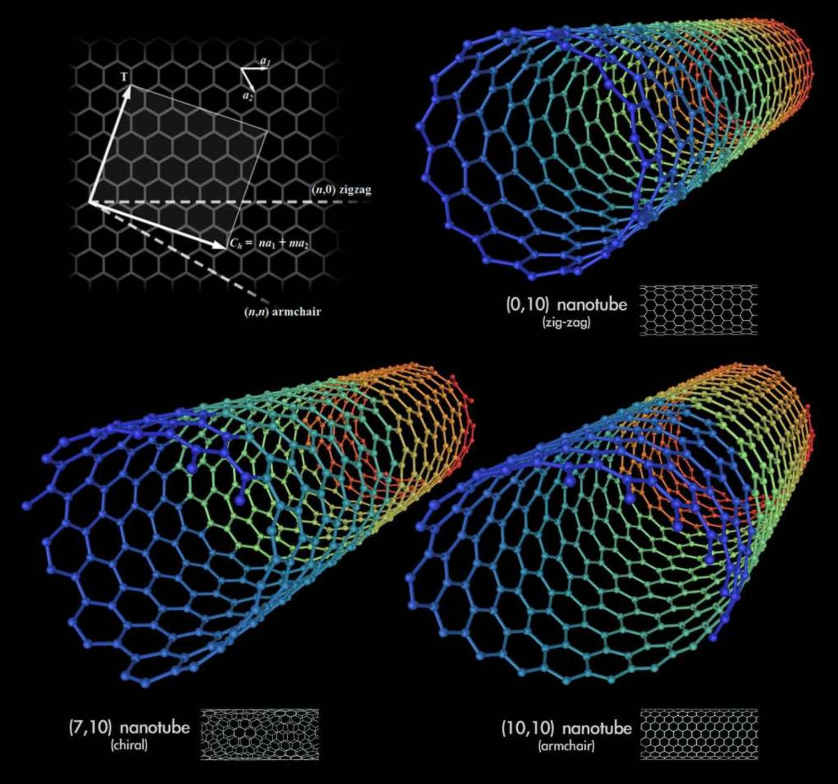

Graphene and carbon nanotubes (CNTs) are revolutionizing AI hardware by addressing limitations in traditional semiconductor materials. Their excellent electrical conductivity and nanoscale size enable faster data processing with lower power consumption. CNTs can replace silicon in transistors, creating smaller and more energy-efficient chips. Graphene interconnects and memory devices are under development to increase data transmission speed. These materials pave the way for ultra-fast processors and neural network accelerators essential in real-time AI applications like autonomous vehicles and smart factories.

Graphene in Battery Applications

Graphene is used to enhance batteries by increasing their conductivity, charge rate, and cycle life. When added to lithium-ion batteries, graphene improves the electrode structure, facilitating faster ion transport. This leads to shorter charging times and longer lifespan. Solid-state batteries also benefit from graphene-based solid electrolytes. Wearable devices, drones, and electric vehicles increasingly rely on such innovations for performance and reliability. As energy demand grows, graphene batteries could transform the energy storage landscape.

Carbon Nanotubes in Smart Packaging

CNTs enhance packaging materials by improving strength, flexibility, and electrical conductivity. In smart packaging, they are used to create sensors and conductive films for tracking and environmental monitoring. CNT-infused packaging can detect temperature, humidity, or damage, ensuring product quality in food, pharmaceuticals, and logistics. They also support printed electronics for barcodes and RFID systems. As industries seek smarter supply chains, CNT-based packaging is becoming a key enabler of automation and data integration.

Graphene in Smart Coatings

Graphene-based coatings are used to improve the durability and performance of mechanical components in smart manufacturing. These coatings offer high corrosion resistance, mechanical strength, and conductivity. For example, in harsh industrial environments, graphene-coated surfaces resist wear and extend the life of critical parts. They also provide anti-static properties, reduce maintenance costs, and enable integration with smart sensors. As manufacturers prioritize longevity and intelligence in their systems, graphene coatings offer a competitive edge.

Graphene as Intelligent Coating

Graphene can also be engineered into multifunctional smart coatings that provide self-cleaning, antibacterial, and anti-corrosion capabilities. These advanced coatings reduce downtime by minimizing maintenance requirements and improving hygiene and reliability in production environments. For instance, self-cleaning surfaces prevent dust accumulation, antibacterial layers protect medical and food-processing equipment, and corrosion resistance prolongs the life of industrial tools. These benefits make graphene coatings an attractive choice for industries demanding high efficiency, cleanliness, and durability.

Carbon Nanotubes in Power Management for Electric Tools and Robots

In electric power tools and robotics, CNTs enhance energy storage and battery management systems. Their high surface area and conductivity make them suitable for electrodes in supercapacitors and lithium-ion batteries. CNT-based batteries charge faster, last longer, and store more energy—enabling uninterrupted operation of autonomous robots, drones, and cordless tools. This supports increased productivity and efficiency in manufacturing and construction sites where downtime is costly.

Graphene and Carbon Nanotube Composites in High-Strength Structural Components

Graphene-CNT hybrid materials combine the best properties of both nanomaterials, producing lightweight yet strong composites. These are ideal for robotic arms, drone frames, and other mechanical parts that require high strength-to-weight ratios. In manufacturing, using such materials can reduce energy consumption and improve motion precision. These composites are being tested in aerospace and automotive sectors for structural reinforcement and mechanical optimization.

Graphene in Wearable Devices

Graphene is increasingly used in wearables for its flexibility, conductivity, and biocompatibility. It supports lightweight sensors embedded into textiles, enabling real-time health and motion monitoring. Graphene-based batteries and supercapacitors power these devices without adding bulk. Furthermore, graphene-enhanced displays offer better contrast and durability. As healthcare and fitness industries push for advanced wearables, graphene is driving innovation in flexible electronics and smart textiles.

Carbon Nanotubes in Wireless Sensor Networks

Carbon nanotubes are enabling a new generation of highly sensitive and energy-efficient sensors used in wireless sensor networks (WSNs). These networks are critical for smart manufacturing, smart cities, and environmental monitoring. CNT-based sensors detect gases, temperature changes, and mechanical stress with high precision and minimal power consumption. Their nanoscale size allows integration into compact and mobile devices. In WSNs, these sensors contribute to real-time data collection, predictive maintenance, and enhanced situational awareness—making them foundational for Industry 4.0 and urban IoT systems.