Exploring the Role of Graphene in the Future of Flexible Electronics

💡 Introduction: A New Era of Bendable Technology

From foldable phones to smart clothing, the future of electronics is shifting toward flexibility. This isn’t just a matter of user convenience — it opens doors to entirely new product categories, such as skin-attached health monitors, roll-up solar panels, and implantable biosensors.

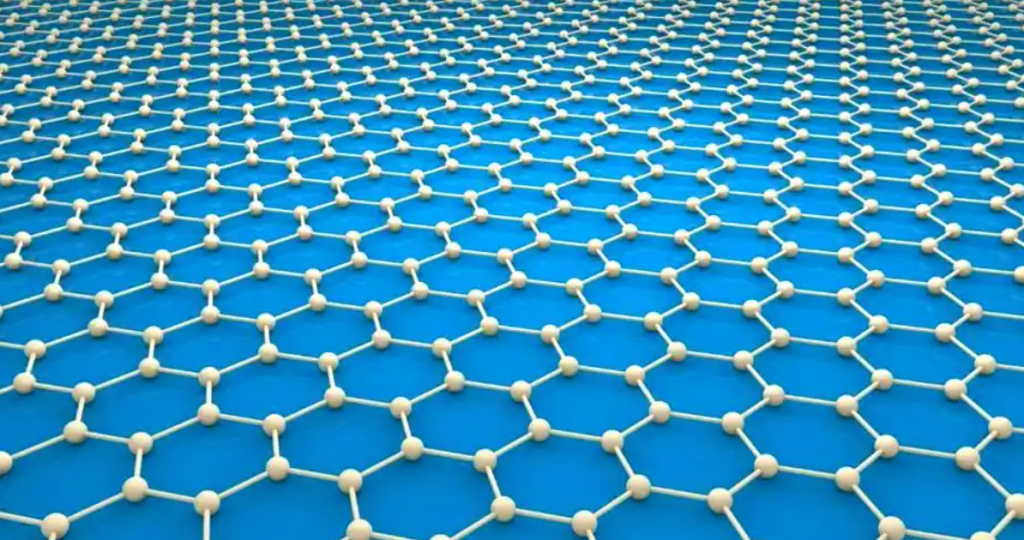

At the heart of this revolution is graphene, a one-atom-thick carbon material with remarkable properties. Its ability to conduct electricity, stretch without breaking, and remain transparent makes it uniquely suitable for flexible electronics.

In this article, we explore how graphene enables flexible devices and why it is considered one of the foundational materials for the next generation of electronics.

🔍 Section 1: Why Flexibility Matters in Modern Electronics

Traditional electronics use rigid materials — silicon, copper, and glass — that cannot bend or deform. This limits their integration into curved or moving surfaces such as:

-

Human skin

-

Clothing

-

Flexible displays

-

Wearable gadgets

Flexible electronics aim to solve these limitations by using stretchable, bendable, and even foldable materials. But this shift demands a new class of electrically and mechanically resilient materials.

That’s where graphene comes in.

⚡ Section 2: Key Properties of Graphene for Flexible Devices

Graphene offers an unmatched combination of features essential for flexible electronics:

| Property | Advantage in Flexible Electronics |

|---|---|

| High Electrical Conductivity | Enables low-resistance circuits on bendable surfaces |

| Extreme Flexibility | Can withstand bending, folding, and stretching |

| Transparency (~97%) | Ideal for displays and optical sensors |

| Thinness | Just one atom thick — minimal weight, easy integration |

| Chemical Stability | Performs reliably under harsh environments |

Its 2D planar structure allows graphene to maintain electron mobility even when stretched or bent, which metals like copper or silver nanowires cannot.

🧪 Section 3: Application Areas and Use Cases

Graphene is being rapidly adopted in the development of multiple flexible devices:

✅ 1. Flexible Touch Screens and Displays

Graphene’s transparency and conductivity make it a natural alternative to ITO (indium tin oxide) in touchscreens:

-

Bendable OLED displays

-

Foldable smartphone screens

-

Wearable curved displays

Samsung, Huawei, and Xiaomi have all filed patents involving graphene electrodes for foldable displays.

✅ 2. Wearable Health Monitors

Graphene-based films can be printed or transferred onto fabrics or skin adhesives, enabling:

-

ECG and EEG sensors

-

Skin temperature monitors

-

Hydration and sweat analysis

-

Movement and pressure sensors

These devices are lightweight, breathable, and stretchable, offering superior comfort and real-time data acquisition.

✅ 3. Flexible Batteries and Supercapacitors

Powering flexible devices requires bendable energy storage, and graphene helps in:

-

Enhancing conductive layers in flexible lithium-ion batteries

-

Serving as electrode material in wearable supercapacitors

-

Acting as a current collector or separator in micro power systems

✅ 4. Stretchable Circuits and E-Textiles

Printed graphene inks or coatings enable electronics to be embedded in fabrics:

-

LED circuits on garments

-

Smart bandages with real-time health feedback

-

Interactive clothing with gesture controls

These circuits remain functional after repeated washing, bending, and stretching.

🛠️ Section 4: Manufacturing Approaches Using Graphene

There are multiple ways to integrate graphene into flexible electronics:

1. Graphene Inks and Pastes

Used in screen printing, inkjet, or roll-to-roll processes:

-

Formulated from graphene oxide (GO), reduced GO (rGO), or few-layer graphene

-

Can be printed on PET, TPU, PDMS, and even paper

2. CVD-Grown Graphene Films

Chemical Vapor Deposition allows the formation of large-area, transparent graphene sheets:

-

Transferred onto flexible substrates like PEN, polyimide, or EVA

-

Offers ultra-high mobility and uniformity

3. Graphene-Coated Threads or Yarns

Used for smart textiles, graphene can be coated on cotton, nylon, or spandex fibers, enabling conductive pathways within wearable garments.

4. Hybrid Composites

Graphene is blended with polymers (PU, PDMS, PVDF) to form conductive elastomers that can stretch and self-heal.

📊 Section 5: Performance Metrics and Benchmarks

Researchers evaluate flexible graphene devices on key parameters:

| Property | Typical Range |

|---|---|

| Sheet Resistance | 30–300 Ω/sq (at >90% transmittance) |

| Bending Radius | Down to 1 mm |

| Conductivity Loss After 1000 Cycles | <10% |

| Stretchability | Up to 20–30% without failure |

| Weight | <1 mg/cm² (ultra-lightweight) |

High-performance devices can withstand thousands of bending cycles with minimal loss in conductivity.

🔬 Section 6: Challenges and Limitations

Despite its promise, several issues need resolution:

-

Large-scale film transfer: CVD graphene is hard to transfer without cracks or defects

-

Contact resistance: Junctions between flakes in ink-printed circuits can introduce resistance

-

Cost: High-purity or large-area graphene films remain relatively expensive

-

Standardization: Lack of unified specs makes performance comparison difficult

However, rapid progress in roll-to-roll printing, laser patterning, and dispersion chemistry is addressing these issues.

🧩 Section 7: GrapheneRich’s Contribution to the Flexible Electronics Market

At GrapheneRich NanoTech, we provide solutions tailored for flexible electronics:

✔️ Aqueous Graphene Dispersions (GO/RGO):

-

Compatible with inkjet and screen printing

-

0.5–5 mg/mL custom concentrations

-

Stable shelf life (1–3 months)

-

pH-adjusted and surfactant-stabilized

✔️ Conductive Graphene Powders:

-

Surface area: 120–150 m²/g

-

Particle size: ~16 µm (custom ranges available)

-

Suitable for polymer composites and screen printing

✔️ Application Support:

-

Printing formulation advice

-

Compatibility with TPU, PDMS, and silicone elastomers

-

Custom hybrid pastes with CNTs or Ag flakes

📩 Contact us for a sample or quote: https://graphenerich.com/contact

🔮 Conclusion: The Path Forward

Graphene is more than a futuristic material — it is already redefining how we think about electronics. From ultra-thin foldable phones to stretchable health monitors, its unmatched combination of electrical, mechanical, and chemical properties puts it at the center of the flexible electronics revolution.

With continuous development in manufacturing, dispersions, and composite integration, graphene will likely play a key role in making truly wearable, foldable, and implantable electronics a reality.

For companies working in smart textiles, medical devices, or next-gen displays, now is the time to explore how graphene materials can transform your products.