Graphene for Structural Composites: Stronger, Lighter, Smarter

🏗️ Introduction: The Evolution of Structural Materials

In the pursuit of stronger, lighter, and more durable materials, composites have transformed the landscape of modern engineering—from aerospace and automotive to construction and consumer electronics. However, traditional fillers like carbon black, talc, or glass fiber face limitations in:

-

Weight reduction

-

Mechanical fatigue resistance

-

Impact toughness

-

Multi-functional properties (e.g., electrical conductivity, corrosion resistance)

Enter graphene—a two-dimensional carbon nanomaterial that offers an exceptional balance of strength, stiffness, and functionality when integrated into composite systems.

🔬 Section 1: Why Graphene? Material Properties That Matter

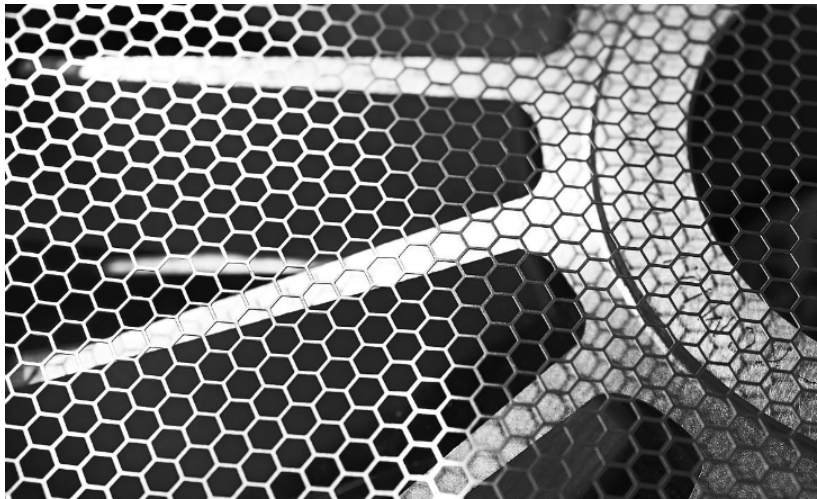

Graphene is a single layer of sp²-bonded carbon atoms arranged in a honeycomb lattice. It boasts:

| Property | Value | Composite Benefit |

|---|---|---|

| Young’s modulus | ~1 TPa | Boosts stiffness & rigidity |

| Tensile strength | ~130 GPa | Improves fracture resistance |

| Surface area | ~2630 m²/g | Better matrix-filler interaction |

| Thermal conductivity | ~3000 W/m·K | Thermal dissipation & stability |

| Electrical conductivity | ~10⁶ S/m | Adds EMI shielding, antistatic features |

These properties are passed on—partially or fully—when graphene is used in polymer, metal, or ceramic matrices.

🧪 Section 2: Common Composite Systems Enhanced by Graphene

Graphene can be integrated into a wide variety of matrix systems, including:

-

Graphene-Polymer Composites

-

Epoxy, polyester, polyurethane, nylon, ABS, PE, PP, etc.

-

Improved tensile strength, flexural modulus, abrasion resistance

-

Ideal for structural panels, shells, parts

-

-

Graphene-Ceramic Composites

-

Alumina, zirconia, silicon carbide matrices

-

Enhances fracture toughness and electrical conductivity

-

Used in cutting tools, biomedical implants, thermal shields

-

-

Graphene-Metal Composites

-

Aluminum, copper, nickel matrices

-

Increases specific strength and fatigue resistance

-

Suitable for aerospace and thermal conduction parts

-

-

Hybrid Carbon Composites

-

Graphene + carbon fiber or CNTs

-

Synergistic performance in aerospace and automotive frames

-

🛠️ Section 3: How Graphene Improves Composite Performance

Even at very low loading levels (0.1–5 wt%), graphene provides meaningful property enhancement:

| Mechanical Property | Typical Improvement | Notes |

|---|---|---|

| Tensile strength | +20–60% | Depends on dispersion |

| Flexural strength | +15–45% | Especially in epoxy systems |

| Toughness | +20–100% | Better crack resistance |

| Fatigue life | 3–10× | For high-cycling components |

| Impact resistance | +40–80% | With few-layer graphene sheets |

Additionally, graphene aids:

-

Thermal management: reduces hotspots in structural materials

-

EMI shielding: especially relevant in electronics-heavy assemblies

-

Barrier protection: against moisture, UV, and chemicals

✈️ Section 4: Industrial Applications of Graphene Composites

| Industry | Component Example | Composite Type |

|---|---|---|

| Aerospace | Wing panels, structural ribs, thermal shields | Graphene-Epoxy, Graphene-Al |

| Automotive | Body panels, under-hood parts, bumpers | Graphene-PP, Graphene-PU |

| Sports Equipment | Bicycle frames, rackets, helmets | Graphene-Nylon, Graphene-CF hybrids |

| Construction | Reinforced concrete, coatings, panels | Graphene-cement, Graphene-polymer films |

| Electronics | Structural EMI shields, sensor housings | Graphene-filled ABS or epoxy |

Case studies have shown up to 30% weight reduction with no sacrifice in strength when replacing conventional carbon or glass fiber composites with graphene-enhanced versions.

🧩 Section 5: Processing Methods & Challenges

Incorporation Techniques:

-

Solution blending: Disperse graphene in solvent with matrix polymer

-

Melt compounding: Twin-screw extrusion or melt mixing

-

In-situ polymerization: Enhances matrix bonding

-

Layer-by-layer assembly: For films or coatings

-

Electrophoretic deposition (EPD): Used for ceramic or metallic coatings

Key Challenges:

| Challenge | Strategy |

|---|---|

| Agglomeration | Use surface-treated graphene or dispersants |

| Poor matrix compatibility | Functionalize with carboxyl, amine, epoxy groups |

| Processing viscosity | Optimize flake size and loading |

| Scaling issues | Work with reliable graphene suppliers (like GrapheneRich!) |

🔧 Section 6: GrapheneRich’s Composite Product Lines

Our graphene products for composites include:

-

GR-RGO-P16: Reduced graphene oxide with 16 µm lateral size, 121 m²/g surface area

-

GR-FLG-A10: Few-layer graphene flakes for epoxy resins

-

GR-Masterbatch Series: Ready-to-use graphene-polymer masterbatches (PE, PP, PU, Nylon)

We support customers with:

-

Customizable loading levels

-

Pre-dispersed solutions or powders

-

Surface modification services

-

Mechanical and thermal performance testing

📈 Section 7: Lab Performance Example

Test: GR-RGO-P16 in epoxy composite (2 wt%)

| Property | Pure Epoxy | GR-RGO Composite |

|---|---|---|

| Tensile strength | 58 MPa | 74 MPa |

| Flexural strength | 90 MPa | 116 MPa |

| Impact resistance | 2.1 kJ/m² | 3.8 kJ/m² |

| Thermal conductivity | 0.22 W/m·K | 0.98 W/m·K |

Result: ~30% strength improvement and ~4.5× thermal conductivity with just 2 wt% loading.

🔮 Section 8: The Future of Structural Composites

Emerging trends include:

-

Smart composites: strain sensing, self-healing with graphene

-

Green composites: using bio-based or recycled matrices

-

Additive manufacturing: 3D-printable graphene-enhanced filaments

-

Aerospace-grade graphene foams: ultra-light and strong

As demands for fuel efficiency, material sustainability, and multi-functionality grow, graphene-enhanced composites will continue to displace legacy systems.

📞 Contact GrapheneRich for Custom Composite Solutions

From material selection to formulation advice and performance testing, we’re here to support your innovation in lightweight and high-performance composites.

📧 Contact us or WhatsApp us: +86 136 1588 2924

We offer free technical consultation and sample kits worldwide.