Graphene-Based Coatings: Enhancing Surface Performance Across Industries

🎯 Introduction: Why Coatings Matter

Surface coatings are essential in nearly every industry—from automotive and aerospace to electronics and infrastructure—providing protection against corrosion, friction, wear, and thermal degradation. However, traditional coatings often struggle to meet the growing demand for multifunctionality, durability, and environmental safety.

Enter graphene-based coatings, a next-generation solution that integrates mechanical strength, chemical resistance, conductivity, and thermal stability in a single ultrathin layer.

🌟 Section 1: What Makes Graphene Ideal for Coatings?

Graphene’s unique structure and chemistry make it a transformative additive or main component in high-performance coatings:

| Property | Benefit in Coatings |

|---|---|

| High surface area (2600 m²/g) | Enhanced barrier against gas/liquid penetration |

| Atom-thick structure | Lightweight yet durable protection |

| Excellent conductivity | Ideal for ESD/EMI protection and heating films |

| High mechanical strength | Anti-scratch and abrasion resistance |

| Chemical inertness | Corrosion and oxidation protection |

| Thermal conductivity | Heat dissipation and fire resistance |

🛡️ Section 2: Application Areas of Graphene Coatings

-

Anti-Corrosion Coatings

-

Use in steel structures, pipelines, offshore equipment

-

Graphene creates a near-impermeable barrier against oxygen, moisture, and salts

-

Replaces toxic heavy-metal additives like chromates

-

-

Wear and Abrasion Resistant Coatings

-

Improves hardness and scratch resistance of polymers and composites

-

Extends service life of automotive, aerospace, and tooling components

-

-

Electrically Conductive Coatings

-

Enables anti-static surfaces, touch panels, and printed circuits

-

Useful in plastic housings, automotive trim, and ESD-sensitive environments

-

-

Thermal Management Coatings

-

Graphene enhances heat dissipation in electronics and LED lighting

-

Used in aerospace, drones, and power modules to reduce thermal stress

-

-

Fire-Retardant Coatings

-

Graphene delays ignition and reduces flame spread

-

Effective in construction panels, textiles, and electronics casings

-

-

Self-Healing or Smart Coatings

-

Graphene supports responsive systems that repair micro-cracks or change color when stressed

-

🧪 Section 3: Formulations and Structures

Graphene coatings come in various formulations:

-

Solvent-based or water-based dispersions

-

Epoxy, polyurethane, acrylic, or silicone matrices

-

Mono-layer or multi-layer architectures

-

Additive level: 0.05%–2% w/w

Common types:

| Type | Description | Applications |

|---|---|---|

| Graphene oxide (GO) | Hydrophilic, easy dispersion in water-based paints | Anti-corrosion, textile coatings |

| Reduced GO (rGO) | Higher conductivity, better hydrophobicity | Conductive inks, EMI shielding |

| Graphene nanoplatelets | High barrier and mechanical strength | Industrial epoxy coatings |

| Functionalized graphene | Customized surface for polymer compatibility | Smart or self-healing coatings |

🏭 Section 4: Example Use Cases Across Industries

| Industry | Use Case | Graphene Function |

|---|---|---|

| Marine | Ship hull coatings | Saltwater corrosion resistance |

| Oil & Gas | Pipeline inner/outer coatings | Anti-corrosion under high pressure |

| Automotive | Bumper or engine bay paints | Anti-scratch, thermal protection |

| Electronics | PCB overcoats, device casings | EMI shielding, heat dissipation |

| Construction | Metal beams, fire doors | Fire-retardant and rustproof coating |

| Textiles | Military uniforms | Anti-microbial and flame-resistant coating |

🧪 Section 5: Lab Case Study – Graphene Epoxy Anti-Corrosion Coating

Experiment Setup:

-

Coating: rGO–epoxy blend, 0.5% wt.

-

Substrate: mild steel panel

-

Environment: 5% NaCl spray, 30 days

Result:

-

90% reduction in corrosion rate

-

Improved adhesion and reduced delamination

-

Stable performance across temperature cycles

This case confirms graphene’s ability to replace chromates and fluoropolymers in protective coatings.

🔬 Section 6: How Graphene Works as a Protective Layer

-

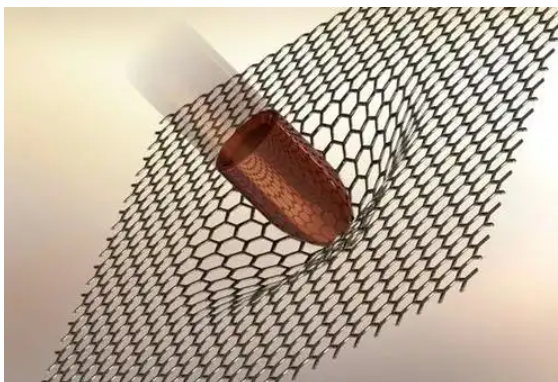

Tortuous Path Barrier

Graphene sheets form a dense mesh, forcing water/oxygen to take long paths, delaying penetration. -

Cathodic Reaction Inhibition

Graphene prevents electrochemical reactions on metal surfaces. -

Hydrophobic Surface Modification

Reduces water uptake and swelling in polymer matrices. -

Thermal Stability

Graphene slows decomposition and improves char yield in fire.

🚧 Section 7: Manufacturing and Application Techniques

Graphene coatings can be applied via:

-

Spray coating (for large surfaces)

-

Dip coating (complex shapes)

-

Spin coating (electronics)

-

Roll-to-roll coating (continuous production)

-

Electrophoretic deposition (EPD) (metal substrates)

🧪 Tip: RGO dispersions like our XFZ20 series can be integrated with industrial binders without extra surfactants.

📦 GrapheneRich Coating-Grade Products

We offer a range of graphene materials ideal for coatings:

-

XFZ20 series RGO dispersions (water-based, for corrosion/EMI)

-

Graphene nanoplatelets (powder for thermoset paints)

-

Conductive graphene inks (flexible coatings)

-

Custom blends with epoxy, PU, silicone matrices

🛠️ Available in 0.5–5 mg/mL dispersions, ready-to-use for formulation or pilot coating projects.

📩 Contact us for a free sample, technical data sheet (TDS), and application recommendations.

📈 Conclusion: Coatings That Do More

Graphene isn’t just a protective layer—it’s a performance booster. Whether you need corrosion resistance, conductivity, thermal management, or mechanical durability, graphene coatings deliver multi-functional protection in a single step.

For coating manufacturers, industrial users, or OEMs, GrapheneRich NanoTech offers advanced materials and formulation support to bring graphene coatings into commercial reality.

🧪 Let’s create coatings that protect smarter, stronger, and longer.