Carbon Nanotubes for Electromagnetic Interference Shielding: High-Performance Lightweight Materials

Introduction

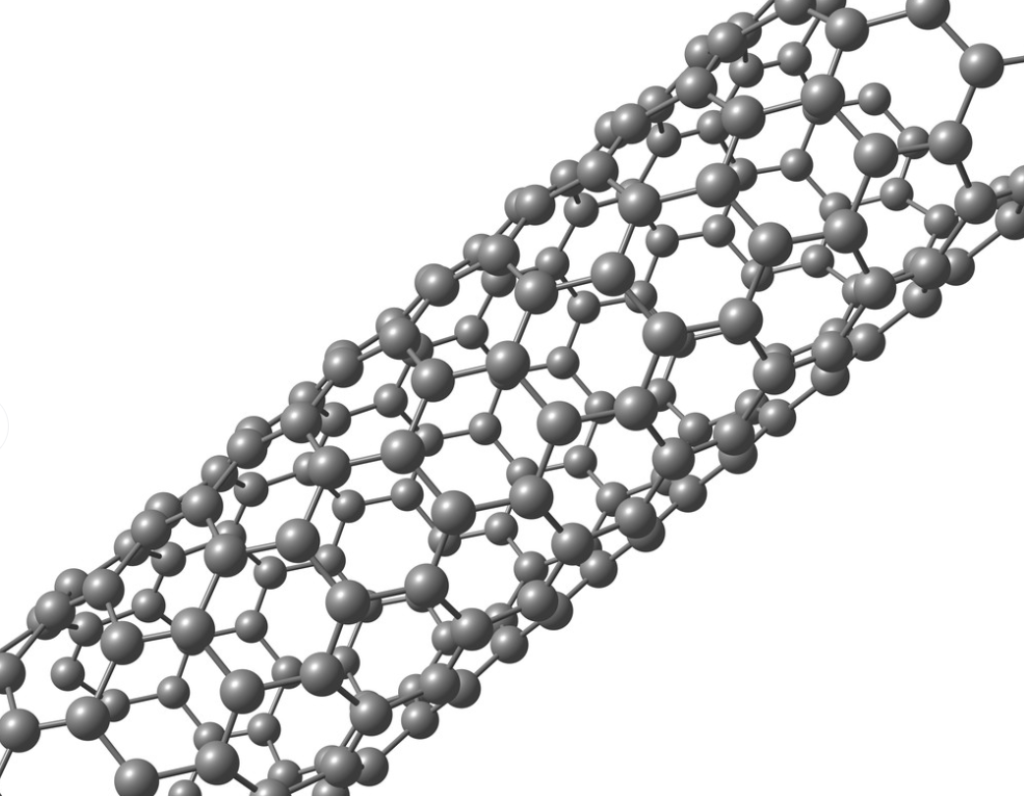

As electronic devices become more compact and interconnected, they also become more susceptible to electromagnetic interference (EMI). Traditional EMI shielding materials like copper or aluminum are heavy, rigid, and often unsuitable for next-generation electronics. Carbon nanotubes (CNTs) have emerged as a promising solution due to their exceptional electrical conductivity, lightweight structure, and compatibility with flexible substrates.

1. What Is EMI and Why It Matters

-

EMI is caused by unwanted electromagnetic signals disrupting electronic devices

-

Can affect military, aerospace, automotive, and consumer electronics

-

Conventional shielding uses metal enclosures or foils, which add weight and volume

2. Why CNTs Are Ideal for EMI Shielding

-

Excellent electrical conductivity enables high EMI attenuation

-

Low percolation threshold allows effective shielding at low filler content

-

High aspect ratio of CNTs forms interconnected conductive networks

-

Lightweight and flexible, ideal for wearables and portable devices

-

Corrosion resistance, unlike metal foils or meshes

3. CNT-Based Composite Types

a. CNT-Polymer Composites

-

Thermoplastics (e.g., ABS, PE, PP) or thermosets (epoxy, polyurethane) as matrices

-

Used in consumer electronics, medical devices

b. CNT-Coated Textiles

-

Lightweight fabrics for aerospace/automotive shielding

-

CNT layers provide EMI protection without stiffening the material

c. CNT-Foams and Aerogels

-

Porous structures with low density

-

Ideal for EMI + thermal insulation

4. EMI Shielding Effectiveness (SE) of CNT Materials

-

SE depends on reflection, absorption, and multiple internal reflections

-

CNT-polymer blends with 3–5 wt% loading show 20–50 dB shielding across 8–18 GHz

-

CNT foams/aerogels can exceed 60 dB in specific designs

-

Flexible films achieve SE ≥ 30 dB while retaining flexibility

5. Application Fields

-

Aerospace: Weight-sensitive EMI shielding in aircraft fuselages

-

Medical Devices: EMI-protected housings for MRI-compatible electronics

-

Automotive: Shielded cable insulation and dashboards

-

5G & IoT Devices: Printed CNT shielding films on PCB and antennas

-

Flexible Electronics: Foldable phones, AR/VR wearables, smart sensors

6. Case Studies

-

Tesla: Investigating CNT-loaded plastic enclosures for battery management units

-

Samsung: Using CNT-coated polymer layers in foldable smartphones

-

Lockheed Martin: Research on CNT-foam for radar-shielded aerospace parts

7. Challenges and Next Steps

-

CNT dispersion: Agglomeration reduces shielding efficiency

-

Cost: High-performance multi-walled CNTs still expensive

-

Durability: Long-term stability under mechanical stress and moisture

-

Regulatory acceptance: Fire-retardant and toxicity standards under evaluation

Conclusion

Carbon nanotubes offer a high-performance, lightweight alternative to metal-based EMI shielding. From flexible electronics to aerospace, CNT composites are redefining how we protect sensitive devices in a signal-heavy environment. With manufacturing technologies maturing, commercial adoption is set to accelerate.