Carbon Nanotubes in Additive Manufacturing: Toward Electrically Functional 3D-Printed Structures

Introduction

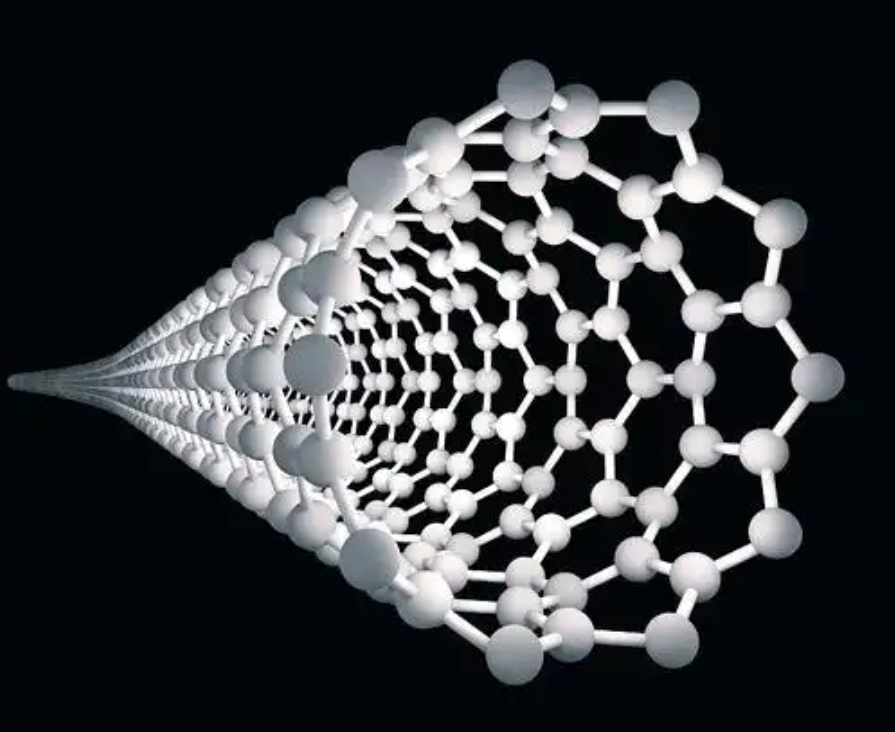

Additive manufacturing (AM), or 3D printing, is evolving rapidly from prototyping to functional end-use components. One of the major challenges is embedding electrical functionality into 3D-printed parts, enabling printed sensors, circuits, and smart structures. Carbon nanotubes (CNTs), with their excellent conductivity and reinforcement properties, are proving essential in this transformation.

1. Why Use CNTs in 3D Printing?

-

Electrical Conductivity: Enables printed traces, antennas, and sensors

-

Mechanical Reinforcement: Improves strength and modulus of printed parts

-

Thermal Conductivity: Supports thermal management in printed electronics

-

Process Compatibility: CNTs can be blended with filaments, resins, and inks

2. Common Approaches

a. Fused Filament Fabrication (FFF)

-

CNTs blended into PLA, ABS, or TPU filaments

-

Enables printing of conductive paths, EMI shielding, strain sensors

b. Direct Ink Writing (DIW)

-

CNT pastes extruded in complex geometries

-

Used for wearable circuits, biomedical scaffolds

c. Stereolithography (SLA)

-

CNT-doped photopolymers allow functional photopolymer parts

-

Requires dispersion techniques to maintain optical curing

3. Key Applications

-

Printed Strain & Pressure Sensors: For structural health monitoring

-

Embedded Circuits: On drones, IoT devices, or medical wearables

-

EMI Shielding Enclosures: For aerospace or sensitive electronics

-

Antennas and RF Components: Lightweight and custom-shaped designs

-

Conductive Jigs and Fixtures: For ESD-safe manufacturing tooling

4. Real-World Progress

-

Nano Dimension: Research on CNT inkjet inks for 3D PCB printing

-

Markforged: Offers carbon fiber and CNT-enhanced filaments

-

MIT: Developed CNT hydrogel ink for bioelectronics printing

5. Challenges in CNT 3D Printing

-

Dispersion and Agglomeration: Affects print quality and conductivity

-

Nozzle Clogging: High aspect ratio CNTs can obstruct extrusion

-

Cost and Consistency: Uniform CNT distribution at scale is difficult

-

Standardization: Material certification for aerospace/biomed applications needed

Conclusion

Carbon nanotubes are transforming 3D printing from structural to functional, enabling the convergence of mechanical integrity with electrical performance. As printer resolution, CNT formulations, and design software mature, we are heading toward an era of truly intelligent printed systems.