Antibacterial and Medical Coatings with Graphene: Advancing Infection-Resistant Surfaces

Hospital-acquired infections (HAIs), bacterial resistance, and the rise of superbugs have prompted the need for advanced antibacterial coatings in medical and industrial environments. Traditional methods, such as silver nanoparticles or chemical disinfectants, pose issues with toxicity, short lifespan, and resistance development.

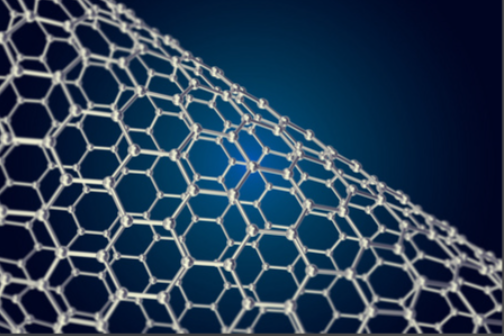

Graphene and its derivatives, particularly graphene oxide (GO) and reduced graphene oxide (rGO), offer a new class of biocompatible, long-lasting, and broad-spectrum antimicrobial coatings, transforming how we approach cleanliness and infection control.

🔹 1. Why Graphene Has Antibacterial Properties

Graphene-based materials interact with microbial cells through:

-

Physical disruption: sharp edges of graphene nanosheets cut into cell membranes

-

Oxidative stress: reactive oxygen species (ROS) formation damages bacterial structures

-

Electron transfer imbalance: graphene acts as an electron acceptor, disrupting respiration

-

Hydrophobic surface: inhibits biofilm adhesion

These mechanisms make graphene effective against Gram-positive and Gram-negative bacteria, fungi, and even viruses.

🔹 2. Types of Graphene-Based Antibacterial Coatings

a. Graphene Oxide (GO) Coatings

-

Rich in oxygen-containing groups

-

Dispersible in water

-

Effective for dip-coating or spraying on medical devices, textiles, and surfaces

b. Reduced Graphene Oxide (rGO)

-

Higher conductivity and chemical stability

-

Suitable for biosensors and surgical tools

c. Graphene Composite Coatings

-

GO blended with polymers, silver nanoparticles, or chitosan

-

Improves synergy between antibacterial and mechanical properties

🔹 3. Applications in the Medical Sector

✅ Surgical Implants

Graphene coatings prevent post-operative infections and biofilm formation on:

-

Orthopedic implants

-

Dental screws

-

Cardiovascular stents

✅ Studies show over 90% bacterial inhibition rate with graphene-coated titanium implants.

✅ Catheters and Tubing

Reduces biofilm accumulation in urinary and vascular catheters, preventing infection-related complications.

✅ Wound Dressings

Graphene-based hydrogels or textile coatings support:

-

Antibacterial barrier

-

Moisture retention

-

Drug delivery of antibiotics or anti-inflammatory agents

✅ Medical Tools and Hospital Surfaces

Graphene-coated scalpel handles, forceps, and high-touch surfaces (e.g., bed rails) maintain long-term antimicrobial resistance with minimal chemical use.

🔹 4. Advantages Over Traditional Antibacterial Agents

| Feature | Silver Nanoparticles | Graphene-based Coatings |

|---|---|---|

| Toxicity Risk | Moderate–High | Low |

| Durability | Short-term | Long-lasting |

| Resistance Risk | Moderate | Low |

| Environmental Safety | Moderate | High |

| Cost Effectiveness | Moderate | Improving with scale |

🔹 5. Graphene in Dental and Orthopedic Coatings

Recent research confirms:

-

Graphene-titania hybrid coatings enhance osteoblast growth and bone integration

-

Graphene-hydroxyapatite composites improve bonding with bone and resist bacterial colonization

-

Used in joint replacements, spinal implants, and maxillofacial plates

🔹 6. Future Directions and Challenges

Research directions:

-

Controlled release systems for antibiotics or healing agents

-

Graphene-textile combinations for smart wound dressings

-

Printable coatings for rapid manufacturing

Challenges:

-

Long-term safety and cytotoxicity (especially at high concentrations)

-

Regulatory acceptance for clinical use

-

Standardization of production and characterization methods

Graphene-based antibacterial coatings are reshaping the landscape of infection control in healthcare and beyond. Their multi-mechanistic microbial inhibition, durability, and biocompatibility make them ideal for medical tools, implants, and surfaces. As manufacturing techniques improve and clinical testing advances, expect graphene to become a cornerstone material in the fight against infections.