Carbon Nanotubes in Flexible Energy Storage: Enabling the Next Generation of Bendable Batteries

As wearable devices, foldable phones, and soft robotics gain traction, there’s a growing need for flexible energy storage systems that match the mechanical properties of the devices they power. Traditional lithium-ion batteries, with rigid structures and metallic electrodes, fall short in flexibility and weight.

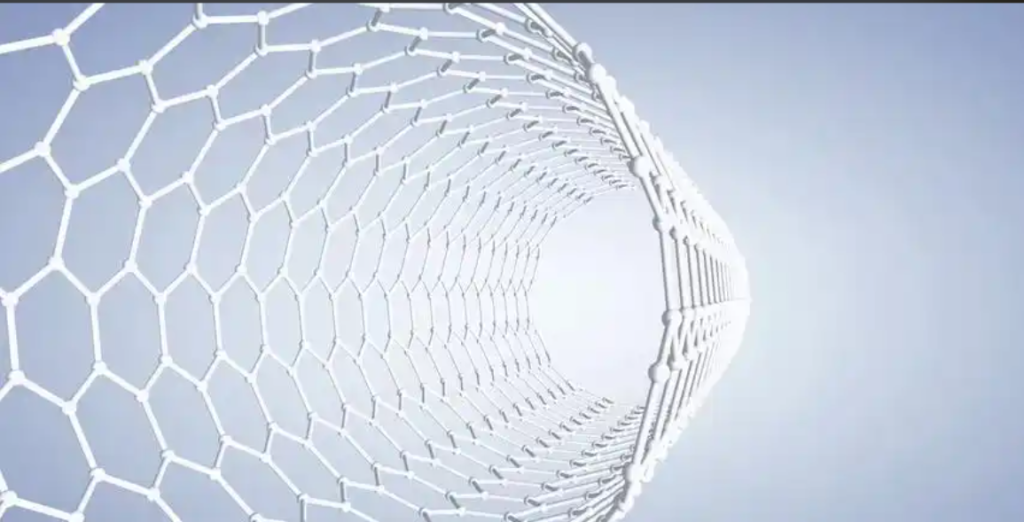

Enter carbon nanotubes (CNTs)—lightweight, conductive, and highly flexible nanomaterials that are redefining battery and supercapacitor design. CNTs serve as electrode materials, current collectors, and reinforcement networks, enabling bendable, stretchable, and even textile-integrated power systems.

🔹 1. Why CNTs Matter in Flexible Batteries

Carbon nanotubes offer:

-

High electrical conductivity (>10⁶ S/m)

-

Mechanical flexibility and resilience

-

Large surface area (~1000 m²/g)

-

High electrochemical stability

These properties make CNTs ideal for:

-

Flexible lithium-ion battery anodes/cathodes

-

Electrodes in wearable supercapacitors

-

Stretchable current collectors in textile electronics

🔹 2. CNTs as Electrodes in Flexible Batteries

✅ CNT-Based Anodes

-

CNTs provide a conductive matrix to host materials like Si, Sn, or LiFePO₄

-

Buffer volume changes during charging

-

Enhance cycle life and rate performance

✅ CNT-Based Cathodes

-

CNTs combine with active materials such as LiCoO₂ or sulfur

-

Improve charge transport and reduce internal resistance

Result: Flexible lithium-ion batteries with CNT networks exhibit high capacity retention (>90% after 1000 cycles) and maintain function under bending or twisting.

🔹 3. CNT Supercapacitors: Powering Instant Energy

CNTs are also extensively used in:

-

Electrochemical double-layer capacitors (EDLCs)

-

Hybrid capacitors with pseudocapacitive materials (e.g., MnO₂, RuO₂)

Advantages:

-

High power density (~10 kW/kg)

-

Rapid charge/discharge cycles

-

Mechanical durability

Flexible CNT supercapacitor sheets are printable, stretchable, and usable in smart patches, helmets, and sportswear.

🔹 4. Flexible Form Factors with CNTs

CNT-based energy storage devices can be made into:

-

Paper-like films

-

Woven fabrics

-

Rollable coils

-

Stretchable serpentines

Techniques include:

-

Spray coating CNT slurries onto polymer films

-

Electrospinning CNT–polymer blends

-

3D printing with CNT-embedded inks

🔹 5. Integration into Wearables and IoT Devices

Use Cases:

-

Smartwatches with curved batteries

-

Wearable biosensors powered by CNT micro-supercapacitors

-

Textile batteries embedded in jackets or gloves

-

Self-charging energy-harvesting wearables

In some systems, CNTs serve both as energy storage and sensing elements, combining power and data in one fiber or patch.

🔹 6. Safety and Environmental Benefits

CNTs also contribute to safety in energy storage:

-

Non-flammable alternatives to liquid electrolytes

-

Thermally stable under deformation

-

Avoid use of heavy metals (when paired with organic electrolytes)

Biodegradable CNT–cellulose composites are being explored for sustainable, low-waste energy systems.

🔹 7. Challenges and Commercial Outlook

| Challenge | Solution |

|---|---|

| CNT dispersion | Functionalization, surfactants |

| Production cost | MWCNTs, scalable synthesis |

| Electrode/electrolyte interface | Gel polymer electrolytes |

| Device packaging | Stretchable encapsulants, thin films |

Global investment in flexible batteries and supercapacitors is expected to surpass USD 10 billion by 2032, and CNTs are central to that roadmap.

Carbon nanotubes are unlocking a future where batteries are as flexible as the devices they power. From curved wearables to soft robots and textile energy storage, CNTs provide the mechanical and electrical backbone for innovation. As manufacturing costs decline and integration advances, CNT-powered flexible energy systems will become ubiquitous in consumer electronics and beyond.