Graphene for Thermal Management in High-Performance Electronics

As electronic devices become faster, smaller, and more powerful, heat management has emerged as one of the most pressing challenges for engineers. Excessive heat not only reduces performance but can also damage critical components, shorten lifespan, and even cause safety hazards. Traditional thermal interface materials (TIMs) such as copper, aluminum, and ceramic composites are reaching their limits in the face of modern high-performance demands. Enter graphene—a carbon-based material renowned for its exceptional thermal conductivity (up to 5,000 W/m·K) and mechanical strength, making it one of the most promising candidates for next-generation thermal management solutions.

Why Thermal Management is Crucial

From smartphones and laptops to electric vehicles and data centers, thermal management is essential to:

-

Prevent Overheating: Prolonged exposure to high temperatures accelerates material degradation.

-

Maintain Performance: Many processors throttle down when they reach critical temperatures, reducing speed to prevent damage.

-

Improve Energy Efficiency: Excess heat results in energy loss.

-

Extend Device Lifespan: Efficient cooling prevents microstructural damage to semiconductors.

In the age of 5G communications, AI data processing, and autonomous vehicles, heat management is no longer a background concern—it’s a central design challenge.

Graphene’s Thermal Advantages

-

Exceptional Thermal Conductivity

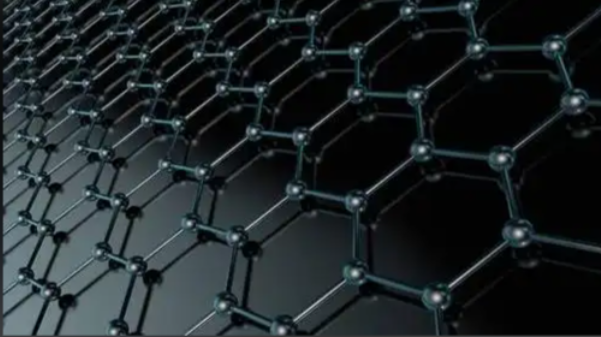

Graphene is composed of a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. This structure allows phonons (heat carriers in solids) to travel with minimal scattering, resulting in thermal conductivity up to 10 times higher than copper. -

Ultra-Thin and Lightweight

Graphene’s atomic thickness allows it to be integrated without significantly increasing the weight or size of the device—critical for mobile and aerospace applications. -

High Mechanical Strength

Despite being extremely thin, graphene is 200 times stronger than steel by weight, meaning it can function as both a heat spreader and a structural reinforcement. -

Flexibility and Transparency

Graphene films can be flexible and even transparent, making them suitable for use in flexible electronics and transparent displays.

Applications in High-Performance Electronics

1. Graphene Heat Spreaders

In smartphones, GPUs, and 5G base stations, graphene sheets are used as heat spreaders to distribute heat evenly across a larger surface area, preventing hotspots. Companies like Huawei and Xiaomi have already integrated graphene films into their flagship smartphones for better thermal control.

2. Graphene Thermal Interface Materials (TIMs)

Graphene-based pastes and composites can replace or enhance traditional TIMs between chips and heat sinks, reducing thermal resistance and increasing heat dissipation efficiency.

3. Cooling for High-Power LEDs

LEDs are highly sensitive to heat; even a small temperature increase can drastically reduce light output and lifespan. Graphene coatings help maintain optimal temperatures for long-term reliability.

4. Graphene in Data Center Cooling

Large-scale data centers generate massive heat loads. Graphene-enhanced cooling modules and coatings improve airflow efficiency and reduce the need for energy-intensive cooling systems.

5. Flexible and Wearable Electronics

Flexible graphene heat spreaders are being used in smartwatches, medical monitoring patches, and foldable displays to keep devices cool without sacrificing design flexibility.

Recent Research and Future Trends

-

Hybrid Graphene Composites

Researchers are combining graphene with polymers or metal nanoparticles to create composite films that retain high thermal conductivity while being easier to produce at scale. -

3D Graphene Architectures

3D porous graphene networks can function as both thermal spreaders and lightweight structural components in aerospace systems. -

Integration with Phase-Change Materials (PCMs)

Graphene-enhanced PCMs can store and release heat efficiently, making them ideal for pulsed high-power devices like laser diodes. -

Large-Scale, Low-Cost Manufacturing

Roll-to-roll CVD production methods are lowering the cost of high-quality graphene films, paving the way for mass adoption in consumer electronics.

Challenges to Overcome

-

Scalability: Producing defect-free graphene in industrial quantities remains challenging.

-

Integration: Compatibility with existing manufacturing processes requires further optimization.

-

Cost: Although prices are dropping, graphene is still more expensive than traditional TIMs.

-

Standardization: Industry-wide performance standards are still in development.

Graphene’s unmatched thermal conductivity, combined with its flexibility, strength, and low weight, positions it as a transformative material for high-performance electronics. As manufacturing techniques mature and costs decline, graphene-based thermal solutions are expected to become mainstream—not just in premium devices but across the entire electronics industry.