Carbon Nanotubes in Advanced Battery Electrodes: Pushing Energy Density Limits

As the global demand for electric vehicles (EVs), renewable energy storage, and portable electronics continues to grow, the need for high-performance batteries becomes more urgent. The industry is pushing for higher energy density, faster charging, and longer cycle life—but traditional electrode materials are reaching their limits.

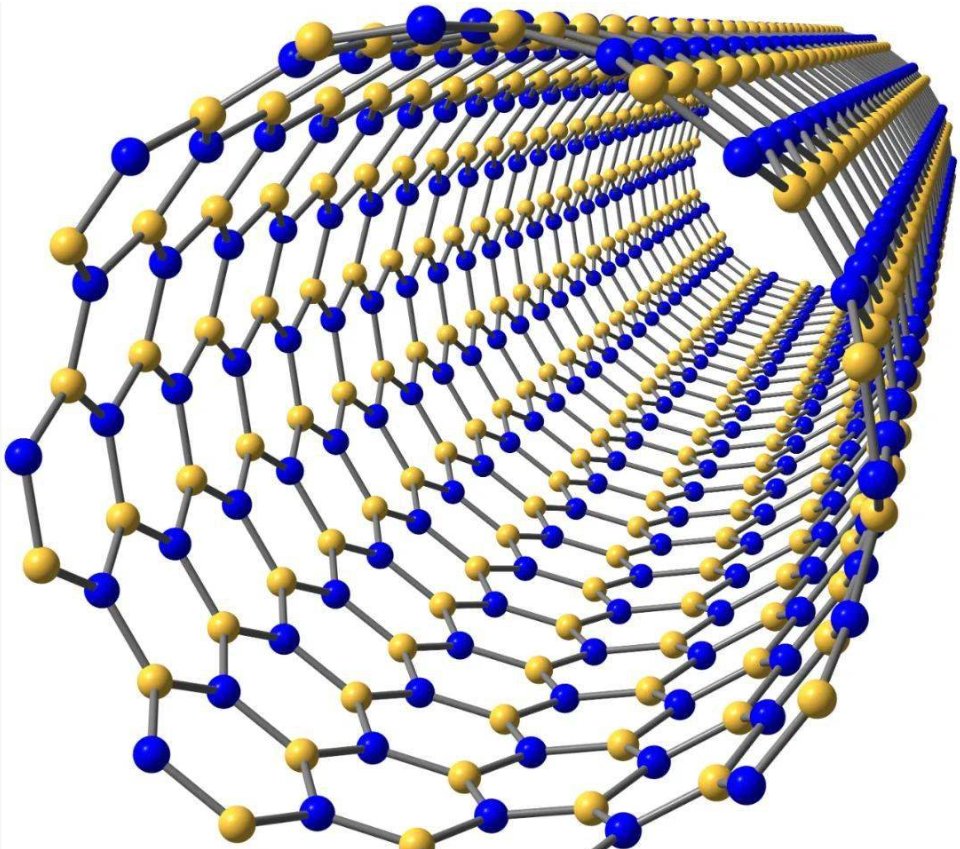

Carbon nanotubes (CNTs), with their exceptional electrical conductivity, mechanical strength, and nanoscale architecture, are emerging as a game-changing electrode material that can overcome these limitations.

Why Carbon Nanotubes for Battery Electrodes?

CNTs offer a unique set of properties that make them ideal for both anodes and cathodes in various battery chemistries:

-

High Electrical Conductivity – Facilitates rapid electron transport, reducing internal resistance.

-

Large Surface Area – Enhances active material loading and reaction kinetics.

-

Mechanical Strength – Prevents electrode cracking during charge–discharge cycles.

-

Porous Network Structure – Enables faster ion diffusion and better electrolyte penetration.

-

Compatibility – Works with lithium-ion, sodium-ion, and even emerging solid-state battery chemistries.

Applications in Battery Electrode Design

1. CNT-Enhanced Lithium-Ion Anodes

-

CNTs can be combined with silicon nanoparticles to create high-capacity anodes.

-

The CNT network provides mechanical support to buffer the volume expansion of silicon during cycling.

-

This significantly extends battery life while maintaining high energy density.

2. CNTs in Cathode Conductive Networks

-

High-energy cathode materials like LiNiMnCoO₂ (NMC) often require conductive additives.

-

Replacing conventional carbon black with CNTs creates a more efficient percolation network, boosting conductivity and capacity retention.

3. Supercapacitor–Battery Hybrids

-

CNTs enable hybrid devices that combine the high energy density of batteries with the fast charge–discharge of supercapacitors.

-

This is especially promising for applications like regenerative braking in EVs.

4. Flexible and Wearable Batteries

-

CNT films can be directly fabricated into flexible electrodes.

-

Ideal for wearable electronics, medical devices, and lightweight aerospace applications where traditional rigid batteries are impractical.

Manufacturing Techniques for CNT Electrodes

-

Vacuum Filtration – Produces uniform CNT films for flexible electrodes.

-

Electrospinning – Combines CNTs with polymers to form nanofiber mats with excellent conductivity.

-

Chemical Vapor Deposition (CVD) – Grows aligned CNT arrays for ultra-high-performance electrodes.

-

Slurry Coating – Integrates CNTs into conventional battery manufacturing lines for scalability.

Challenges to Overcome

-

Cost of High-Purity CNTs – Large-scale production remains expensive.

-

Dispersion and Integration – CNTs tend to agglomerate, requiring advanced dispersion techniques.

-

Electrode–Electrolyte Compatibility – Surface modifications may be needed for optimal ion interaction.

Future Outlook

The CNT electrode market is projected to grow rapidly alongside the expansion of EVs and stationary energy storage systems. Anticipated developments include:

-

Vertically Aligned CNT Electrodes – For ultrafast charging.

-

Binder-Free CNT Electrodes – Increasing energy density by eliminating inactive materials.

-

Hybrid Nanostructures – Combining CNTs with graphene or MXenes for synergistic performance gains.

Carbon nanotubes are not just a promising research material—they are actively entering commercial battery production, particularly for high-performance and niche applications.

As manufacturing scales and integration methods mature, CNT-based electrodes could enable batteries that charge in minutes, last for decades, and store far more energy than today’s technologies allow—accelerating the global shift toward electrification.