CNTs in EMI Shielding for Aerospace: Lightweight Protection for the Next Era of Flight

In the aerospace industry, electromagnetic interference (EMI) poses a critical challenge. Aircraft and spacecraft rely on highly sensitive electronic systems for navigation, communication, propulsion, and safety. However, the dense use of electronics and exposure to external radiation make these systems vulnerable to EMI.

Traditionally, EMI shielding has relied on metallic enclosures such as copper or aluminum. While effective, metals add considerable weight, which directly impacts fuel efficiency, payload capacity, and overall mission cost.

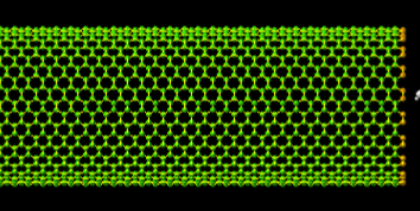

Enter carbon nanotubes (CNTs) — advanced nanomaterials offering exceptional electrical conductivity, lightweight structure, and mechanical strength. CNT-based composites are emerging as a next-generation EMI shielding solution for aerospace, balancing high performance with reduced weight.

1. The Importance of EMI Shielding in Aerospace

-

Safety Concerns

-

EMI can disrupt avionics, flight control systems, and satellite communications.

-

In worst cases, interference may cause catastrophic system failures.

-

-

Growing Electronic Density

-

Modern aircraft contain hundreds of sensors, processors, and wireless systems.

-

Electric aircraft (eVTOLs, hybrid planes) increase EMI exposure further.

-

-

Space Applications

-

Satellites and spacecraft operate in high-radiation environments.

-

EMI shielding is essential for long-duration missions and reliable communication.

-

2. Why CNTs? Unique Material Properties for EMI Shielding

CNTs offer advantages over traditional shielding materials:

-

High Electrical Conductivity

-

Enables efficient absorption and reflection of electromagnetic waves.

-

-

Lightweight

-

CNT composites are 70–90% lighter than metal shields, crucial for aerospace weight reduction.

-

-

Mechanical Strength & Flexibility

-

CNT-reinforced polymers maintain durability even in extreme aerospace conditions.

-

-

Thermal Stability

-

CNTs withstand high operating temperatures, important for jet engines and spacecraft.

-

-

Processability

-

CNTs can be embedded into polymers, coatings, or composite laminates, compatible with existing aerospace manufacturing.

-

3. CNT-Based EMI Shielding Approaches

-

CNT-Polymer Composites

-

CNTs dispersed in epoxy or thermoplastics provide conductive shielding while keeping structures lightweight.

-

Can be molded into panels, covers, or housings.

-

-

CNT-Coated Fabrics and Films

-

Ideal for flexible shielding applications inside cockpits or satellite cabins.

-

Offer conformal coverage without metal foils.

-

-

Hybrid CNT-Metal Composites

-

Combining CNTs with metals (like aluminum flakes) enhances conductivity while reducing overall metal usage.

-

-

Sprayable CNT Coatings

-

Applied directly onto aircraft structures for localized EMI shielding.

-

Useful for retrofitting or repairs.

-

4. Performance Benefits for Aerospace Applications

-

Weight Reduction

-

Every 1% weight reduction can save millions in fuel costs over an aircraft’s lifespan. CNTs enable substantial weight savings compared to copper or aluminum shields.

-

-

Enhanced Durability

-

CNT composites resist corrosion, unlike metals, reducing maintenance costs.

-

-

Broadband EMI Protection

-

CNTs shield against a wide frequency range, from radar signals to communication bands.

-

-

Integration with Structural Materials

-

CNT composites can serve dual roles: mechanical reinforcement + EMI shielding.

-

-

Design Flexibility

-

Lightweight CNT films or coatings allow innovative aircraft designs where metallic shielding would be impractical.

-

5. Industrial Developments and Case Studies

-

NASA

-

Exploring CNT-polymer composites for spacecraft shielding, reducing launch weight while maintaining reliability.

-

-

Airbus

-

Investigating nanomaterial-based EMI shielding to enhance next-gen aircraft efficiency.

-

-

Lockheed Martin

-

Developing lightweight CNT composites for satellites and defense applications.

-

-

Commercial Nanomaterial Suppliers

-

Companies like Nanocomp Technologies (USA) and Arkema (France) scaling CNT materials specifically for aerospace EMI shielding.

-

6. Market and Trade Opportunities

For exporters and suppliers, CNT-based EMI shielding offers high-potential entry points:

-

Aircraft OEMs – demand lightweight materials for fuel savings.

-

Defense Contractors – require advanced EMI shielding for radar and stealth systems.

-

Satellite Manufacturers – need radiation-tolerant, lightweight shielding solutions.

-

Maintenance and Retrofit Providers – could adopt CNT-based coatings as aftermarket upgrades.

Given the globalization of aerospace supply chains, opportunities exist for specialized component exporters in Asia, Europe, and North America.

7. Challenges to Overcome

-

Cost of High-Quality CNTs – scalable, affordable production is still developing.

-

Material Standardization – aerospace requires stringent certification, and CNT composites must pass long-term reliability tests.

-

Dispersion and Processing – ensuring uniform CNT distribution in polymers remains technically challenging.

Carbon nanotubes offer a transformative solution to the challenge of EMI shielding in aerospace. By combining lightweight performance, conductivity, and durability, CNT-based materials can significantly reduce aircraft weight while ensuring safety and reliability.

As the aerospace industry moves toward electric propulsion, higher data loads, and more connected systems, CNTs are well-positioned to become a mainstream material for EMI shielding. For suppliers and exporters, this represents an exciting frontier in advanced materials trade.