CNTs in Next-Gen Microprocessors: Unlocking the Future of High-Performance Computing

For decades, the semiconductor industry has followed Moore’s Law, doubling transistor density roughly every two years. However, as silicon-based microprocessors approach physical and thermal limits, further scaling becomes increasingly difficult. Challenges such as power leakage, heat generation, and short-channel effects have slowed progress.

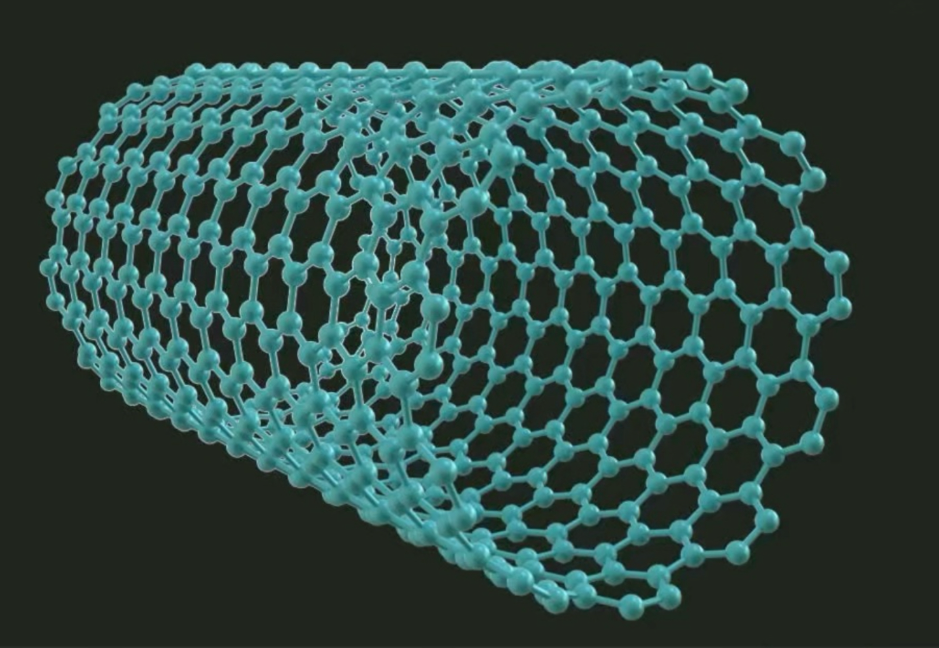

This has opened the door to new materials that can extend the life of microprocessors beyond silicon. Among them, Carbon Nanotubes (CNTs) are widely seen as one of the most promising candidates. With their extraordinary electrical conductivity, nanoscale dimensions, and thermal performance, CNTs are poised to transform the next generation of microprocessors and integrated circuits (ICs).

1. Why CNTs Are Ideal for Microprocessors

CNTs possess a set of properties that align perfectly with the demands of modern processors:

-

Superior Electrical Conductivity

-

CNTs can act as near-ballistic conductors, minimizing resistance and power loss.

-

-

Nanoscale Size

-

CNTs can form transistors much smaller than conventional silicon MOSFETs, allowing ultra-high-density integration.

-

-

High Switching Speed

-

CNT transistors demonstrate switching speeds 5–10x faster than silicon-based devices.

-

-

Low Power Consumption

-

CNT-based FETs (Field Effect Transistors) operate with significantly lower leakage currents, improving energy efficiency.

-

-

Thermal Conductivity

-

CNTs efficiently dissipate heat, reducing thermal bottlenecks in dense processor architectures.

-

2. CNT Applications in Microprocessors

a. CNT Field Effect Transistors (CNT-FETs)

-

CNT-FETs are seen as the direct replacement for silicon MOSFETs.

-

They enable sub-5 nm transistor nodes, offering superior current density and faster switching.

-

IBM and Stanford have demonstrated working prototypes with tens of thousands of CNT transistors integrated into functional circuits.

b. CNT Interconnects

-

Traditional copper interconnects face electromigration and resistance issues at nanoscale.

-

CNT bundles offer high current carrying capacity and reliability, extending chip lifetimes.

c. CNT-Based Logic and Memory Circuits

-

CNTs are being tested for logic gates, SRAM cells, and DRAM architectures.

-

Their nanoscale geometry allows high-density memory integration.

d. CNTs in 3D and Heterogeneous Integration

-

CNTs can serve as vertical interconnects (vias) in 3D-stacked chips.

-

They also enable hybrid integration with silicon, offering a gradual transition path for manufacturers.

3. Industry Progress and Case Studies

-

IBM Research

-

Demonstrated CNT transistors with channel lengths below 10 nm, outperforming silicon MOSFETs.

-

-

Stanford University

-

Built the world’s first CNT-based computer in 2013, proving CNTs could perform basic logic operations.

-

-

TSMC and Intel

-

Actively exploring CNT interconnects for future chip generations.

-

-

DARPA Programs (USA)

-

Funding CNT-based computing for defense and aerospace applications, targeting high-speed, low-power processors.

-

These advances suggest that CNTs may become commercially viable within the next decade, potentially replacing silicon at advanced nodes (sub-3 nm).

4. Benefits Over Silicon and Alternatives

-

Silicon vs. CNTs

-

Silicon transistors face leakage and performance barriers below 5 nm. CNTs can scale further with superior energy efficiency.

-

-

CNTs vs. Graphene

-

While graphene is an excellent conductor, its lack of a natural bandgap limits transistor use. CNTs, by contrast, can exhibit a tunable bandgap, making them suitable for digital logic.

-

-

CNTs vs. Other Materials (GaN, MoS₂, etc.)

-

CNTs combine high current density, low power consumption, and scalability better than most alternatives.

-

5. Market Opportunities for Exporters and Integrators

Although CNT microprocessors are still in pre-commercial stages, the surrounding ecosystem already offers opportunities:

-

CNT Materials Supply

-

Supplying high-purity, semiconducting CNTs is critical for IC fabrication. Exporters who can provide reliable CNT materials will find growing demand from R&D labs and semiconductor companies.

-

-

Research and Prototyping Equipment

-

CNT inks, dispersions, and wafer-scale deposition tools are in demand by universities and chip startups.

-

-

IoT and Edge Computing Devices

-

As CNT processors mature, small and mid-sized integrators will be early adopters in wearables, medical devices, and IoT sensors.

-

-

Thermal Management Solutions

-

CNTs can also serve as thermal interface materials (TIMs) in processors, creating additional trade opportunities.

-

For exporters in the energy storage and electronics trade space, this overlap creates new product lines beyond batteries and ESS — expanding into advanced electronics and CNT-based materials.

6. Challenges and Future Outlook

-

Material Purity and Consistency

-

CNTs must be sorted into metallic vs. semiconducting types. High purity (>99.9%) is required for reliable transistor performance.

-

-

Scalability

-

Wafer-scale CNT alignment and integration remain costly and technically challenging.

-

-

Industry Transition

-

The semiconductor industry has billions invested in silicon. Transitioning to CNTs requires gradual hybrid approaches.

-

Despite these challenges, most experts predict that CNT-based transistors will enter mainstream manufacturing within 10–15 years, first in specialized processors (defense, AI accelerators, space computing), followed by consumer electronics.

As silicon approaches its scaling limits, Carbon Nanotubes represent the next frontier in microprocessor design. With their exceptional conductivity, nanoscale structure, and energy efficiency, CNTs are set to redefine what processors can achieve in terms of speed, power, and integration density.

For exporters and technology integrators, this sector provides a long-term opportunity: early participation in CNT materials and electronic components can secure future partnerships in a market that will shape next-gen computing, AI, and IoT.