CNTs in Smart Prosthetic Devices: Enhancing Performance and Bio-Integration

The prosthetics industry has advanced significantly, moving beyond simple mechanical replacements to smart prosthetic devices that integrate electronics, sensors, and advanced materials. These innovations aim to rest ore mobility, dexterity, and sensory feedback, bringing prosthetics closer to natural limb performance.

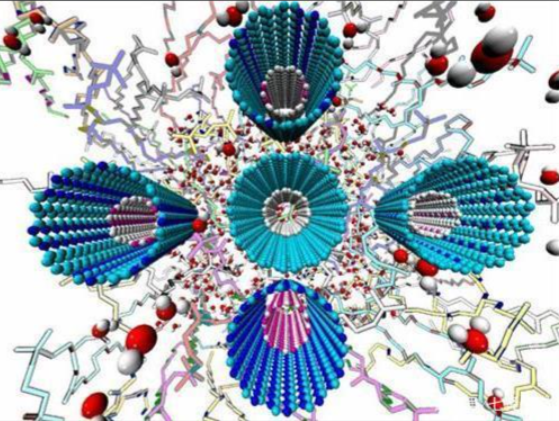

A key challenge remains: how to create lightweight, durable, and responsive prosthetics that seamlessly interact with the human nervous system. Carbon nanotubes (CNTs), with their exceptional electrical conductivity, mechanical strength, and biocompatibility, are emerging as a transformative material for next-generation prosthetics.

This article explores how CNTs are shaping smart prosthetic devices, from neural interfaces to structural composites, and what opportunities lie ahead for exporters and technology integrators.

1. Why CNTs are Relevant to Prosthetics

CNTs bring multiple functionalities critical for prosthetic design:

-

Electrical Conductivity

-

CNTs conduct electricity at levels comparable to metals, making them ideal for neural signal transmission and biosensors.

-

-

Mechanical Strength & Flexibility

-

CNTs are 100x stronger than steel while remaining lightweight, perfect for load-bearing prosthetic structures.

-

-

Biocompatibility

-

CNTs can be functionalized to reduce immune rejection and improve integration with biological tissues.

-

-

Surface Area for Sensors

-

High surface-to-volume ratio allows CNTs to enhance biosensor sensitivity in prosthetics.

-

-

Thermal & Wear Resistance

-

CNT-reinforced composites withstand daily stresses, extending prosthetic lifetime.

-

2. Applications of CNTs in Smart Prosthetic Devices

a. Neural Interfaces and Signal Transmission

-

CNT-based electrodes enable direct communication between nerves and prosthetics, improving control accuracy.

-

Used in brain-computer interface (BCI) systems to allow intuitive movement of artificial limbs.

b. Biosensors and Feedback Systems

-

CNT coatings on sensors detect pressure, strain, and temperature, allowing prosthetics to “feel.”

-

These sensors provide haptic feedback to users, improving object handling and safety.

c. Structural Reinforcement

-

CNT composites in prosthetic sockets and joints reduce weight while increasing durability.

-

Better load distribution reduces discomfort for users.

d. Energy Storage and Power Supply

-

CNT supercapacitors integrated into prosthetics enable lightweight, fast-charging energy systems.

-

Enhances autonomy of motorized prosthetic arms and legs.

e. Antimicrobial and Healing Functions

-

CNTs can be functionalized with antimicrobial properties, reducing infection risks at attachment points.

3. Industry Developments and Case Studies

-

University of Michigan (USA)

-

Developed CNT-based neural interfaces for precision prosthetic control.

-

-

CNRS (France)

-

Demonstrated CNT-coated electrodes with improved signal clarity and reduced scarring.

-

-

Prosthetics Startups (Europe & Asia)

-

Exploring CNT composites in lightweight limb sockets for better comfort.

-

-

Biomedical Device Trials in China

-

Testing CNT biosensors in prosthetics for temperature and tactile sensing.

-

4. Advantages Over Conventional Materials

-

CNTs vs. Metal Electrodes

-

CNTs are more flexible and biocompatible, reducing tissue damage and rejection.

-

-

CNTs vs. Standard Polymers

-

CNT composites offer higher strength without added weight.

-

-

CNTs vs. Silicon Sensors

-

CNT-based biosensors are more sensitive, durable, and adaptable.

-

5. Market Opportunities for Exporters and Integrators

The smart prosthetics market is projected to reach $8–10 billion by 2030, with strong demand for advanced materials and sensors. CNT applications create business opportunities in:

-

Medical Device Supply Chains

-

Export CNT-coated sensors and electrodes for prosthetics.

-

-

Composite Material Providers

-

Offer CNT-reinforced polymers for prosthetic structures.

-

-

Wearable Tech Integrators

-

Supply CNT-based flexible electronics for haptic feedback.

-

-

Healthcare Export Markets

-

SMEs can target Asia-Pacific and Europe, where demand for affordable smart prosthetics is growing.

-

6. Challenges and Future Outlook

-

Biocompatibility and Safety

-

Long-term effects of CNTs in the human body still require further clinical validation.

-

-

Cost of CNT Production

-

High-quality CNTs are still expensive, limiting mass-market adoption.

-

-

Regulatory Hurdles

-

Medical device approval requires extensive testing and certification.

-

-

Future Trend

-

Hybrid CNT + graphene composites may combine conductivity, flexibility, and strength for prosthetics.

-

Integration with AI-driven prosthetic control systems will further enhance performance.

-

CNTs are redefining the future of smart prosthetic devices, enabling lightweight structures, precise neural control, and sensory feedback. With their unique combination of mechanical, electrical, and biological compatibility, CNTs can bridge the gap between prosthetics and natural limb function.

For exporters and technology integrators, CNT-enhanced prosthetics present a high-value niche market with significant potential in medical devices and healthcare innovation. As research progresses and costs decrease, CNT-enabled prosthetics will move from clinical prototypes to mainstream healthcare solutions, improving the quality of life for millions worldwide.