CNTs in Transparent Conductive Films: The Future Beyond ITO

Transparent conductive films (TCFs) are essential materials in modern electronics. From smartphone touchscreens to solar panels and flexible displays, TCFs enable devices to conduct electricity while remaining optically transparent. For decades, indium tin oxide (ITO) has been the industry standard. However, ITO comes with significant limitations: it is brittle, expensive, and difficult to use in flexible electronics.

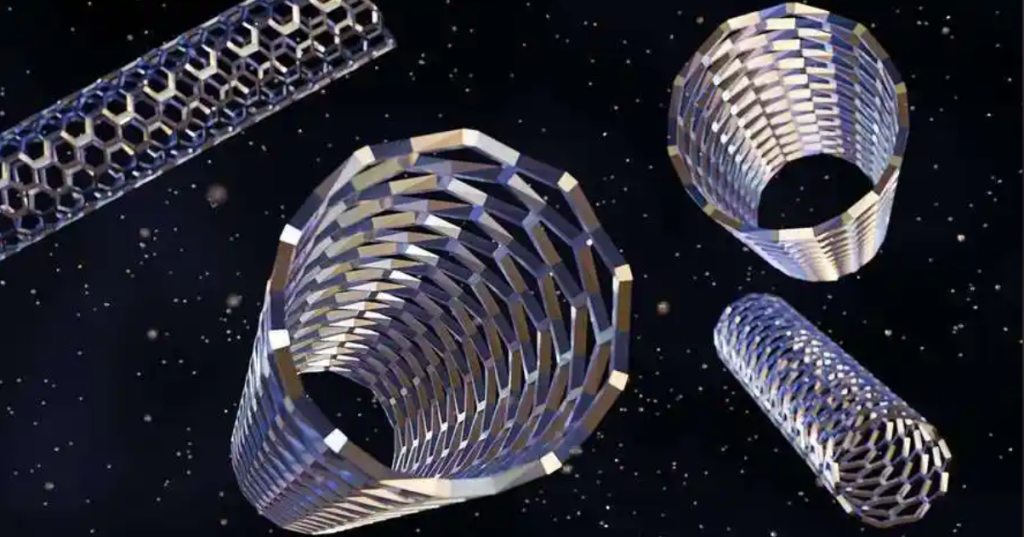

Enter carbon nanotubes (CNTs)—one of the most promising nanomaterials in the field of transparent conductors. With their remarkable electrical, mechanical, and optical properties, CNTs are quickly gaining attention as a potential alternative to ITO, paving the way for more sustainable, flexible, and cost-effective electronic devices.

This article explores how CNT-based transparent conductive films work, their advantages over traditional materials, industrial applications, market outlook, and the challenges that still need to be addressed.

What Are Transparent Conductive Films?

Transparent conductive films are thin coatings that combine two critical properties:

-

Electrical conductivity – allowing current to flow across surfaces.

-

Optical transparency – maintaining visibility for displays, windows, or solar cells.

The most common TCF material today is ITO. However, its disadvantages include:

-

Scarcity of Indium → driving high material costs.

-

Brittleness → unsuitable for bending or stretching in flexible electronics.

-

High processing cost → vacuum deposition techniques increase manufacturing expenses.

These drawbacks have accelerated the search for alternative TCF materials such as silver nanowires, graphene, conductive polymers, and carbon nanotubes.

Why CNTs? The Science Behind Their Properties

Carbon nanotubes are cylindrical structures made of rolled-up sheets of graphene. Depending on their structure (single-walled CNTs, SWCNTs, or multi-walled CNTs, MWCNTs), they can exhibit metallic or semiconducting behavior.

Key properties that make CNTs ideal for TCFs include:

-

High Electrical Conductivity → CNT networks form percolation paths for electron transport.

-

Excellent Optical Transparency → CNTs absorb minimal visible light, allowing >90% transparency when processed correctly.

-

Mechanical Flexibility → unlike brittle ITO, CNT films can bend, stretch, and fold without losing conductivity.

-

Chemical Stability → resistant to oxidation and environmental degradation.

-

Scalable Processing → CNTs can be deposited using solution-based methods like spraying, printing, or coating, lowering production costs.

Advantages of CNT-Based Transparent Conductive Films

1. Flexibility and Durability

CNT networks maintain conductivity even under repeated bending or stretching, making them ideal for flexible displays, wearable electronics, and foldable smartphones.

2. Cost Efficiency

Indium is rare and expensive, while CNTs can be synthesized in bulk using chemical vapor deposition (CVD) or other scalable methods. As CNT production costs continue to fall, they offer a more affordable long-term solution.

3. Lightweight and Thin

CNT films are lightweight and can be applied as ultra-thin coatings, reducing device weight without compromising performance.

4. Environmental Benefits

Unlike ITO, CNTs do not rely on scarce elements. CNT-based TCFs align with sustainability goals by reducing dependence on rare materials.

5. Compatibility with Roll-to-Roll Manufacturing

CNT inks can be processed using printing or spray-coating methods compatible with large-scale, low-cost production lines.

Industrial Applications

1. Touchscreens and Displays

CNT-based TCFs can replace ITO in smartphones, tablets, and televisions. Their flexibility allows future devices to be foldable, rollable, and more durable.

2. Flexible and Wearable Electronics

From smartwatches to electronic textiles, CNT films enable devices that bend with the human body without breaking electrical circuits.

3. Solar Panels and Photovoltaics

Transparent electrodes are critical in solar cells. CNT TCFs offer better mechanical stability for next-generation lightweight and flexible solar panels.

4. OLEDs and LED Lighting

CNTs provide efficient charge transport in organic light-emitting diodes and thin-film LEDs, improving device performance and lifespan.

5. Transparent Heaters and Sensors

CNT films can act as transparent heating elements for car windshields, smart windows, or anti-fogging systems. Their conductivity and stability also make them suitable for transparent sensors.

CNTs vs. Other Alternatives

Other ITO alternatives exist, but CNTs have unique advantages:

-

Silver Nanowires (AgNWs): Excellent conductivity but prone to oxidation and poor adhesion.

-

Graphene: Promising but still faces challenges in large-area uniformity and sheet resistance.

-

Conductive Polymers (e.g., PEDOT:PSS): Flexible but less stable under humidity and heat.

Compared to these, CNTs strike a balance between conductivity, transparency, flexibility, and cost-effectiveness.

Market Trends and Commercial Potential

The transparent conductive films market is projected to exceed USD 10 billion by 2030, with growing demand from consumer electronics, automotive, and renewable energy sectors.

CNT-based TCFs are gaining momentum due to:

-

Rapid expansion of flexible electronics.

-

Rising costs of ITO production.

-

Increasing investment in nanotechnology R&D.

Major players and startups are already scaling CNT-based films. For example, companies in Asia, Europe, and the US are integrating CNT coatings into touchscreens, smart windows, and energy devices.

Challenges to Overcome

Despite strong potential, several hurdles remain before CNT films can fully replace ITO:

-

Sheet Resistance vs. Transparency Trade-Off: Achieving both low resistance and high optical transparency is still challenging.

-

Purity and Sorting of CNTs: Metallic vs. semiconducting CNT ratios must be controlled for consistent performance.

-

Surface Uniformity: Large-area films require precise coating techniques to avoid defects.

-

Standardization: Industry adoption requires internationally accepted benchmarks and certification methods.

Researchers are actively addressing these challenges through advanced synthesis, chemical doping, hybrid materials (CNT + graphene), and optimized deposition techniques.

Future Outlook

Looking ahead, CNT-based transparent conductive films are expected to play a major role in next-generation electronics. Key developments may include:

-

Hybrid CNT-Graphene Films → combining the best properties of both nanomaterials.

-

Printed CNT Inks → enabling ultra-low-cost roll-to-roll electronics.

-

Integration with Smart Windows & AR/VR Devices → enhancing optical performance while maintaining flexibility.

-

Mass Adoption in Wearables → as healthcare and IoT devices demand transparent, flexible, and durable materials.

As the demand for sustainable and flexible technologies grows, CNT films are poised to become a mainstream alternative to ITO in the coming decade.

Carbon nanotubes are redefining the landscape of transparent conductive films. By overcoming the limitations of brittle and costly ITO, CNTs enable the creation of flexible, lightweight, and sustainable electronic devices.

From touchscreens to solar panels, CNT-based TCFs offer a versatile solution that combines excellent conductivity, high transparency, mechanical durability, and cost-effectiveness. While challenges remain in large-scale production and performance optimization, rapid research progress and industrial adoption indicate a bright future for CNT technology.

Businesses and researchers who embrace CNT-based TCFs today will be at the forefront of the next revolution in flexible and transparent electronics.