Graphene in High-Speed Rail Infrastructure: Building the Future of Transportation

High-speed rail (HSR) is transforming global transportation by offering fast, efficient, and sustainable travel. From China’s extensive bullet train network to Europe’s cross-border connections, rail systems are expanding rapidly. However, building and maintaining high-speed rail infrastructure poses significant challenges: tracks must withstand extreme loads, bridges must resist fatigue, and construction materials must deliver long lifespans with minimal maintenance.

Enter graphene, the nanomaterial often hailed as the “wonder material.” With its extraordinary strength, electrical conductivity, and durability, graphene is reshaping how infrastructure is designed and built. In high-speed rail, graphene offers solutions for stronger concrete, longer-lasting composites, and smarter maintenance systems, ultimately enabling safer and more cost-effective rail networks.

This article explores how graphene is revolutionizing high-speed rail infrastructure, its applications, benefits, and future outlook.

The Challenges of High-Speed Rail Infrastructure

High-speed railways face unique stresses compared to conventional rail:

-

Intense Mechanical Loads – trains running at 300+ km/h exert massive pressure on tracks and bridges.

-

Vibration and Fatigue – repeated cycles cause material degradation.

-

Weather and Environmental Factors – temperature swings, humidity, and corrosion reduce durability.

-

Maintenance Costs – track repair, concrete replacement, and downtime are expensive.

-

Sustainability Goals – governments demand greener, longer-lasting materials.

Traditional materials like concrete, steel, and asphalt have limitations in handling these extreme conditions. Graphene-enhanced materials provide a new frontier of resilience and efficiency.

Why Graphene? The Material Advantage

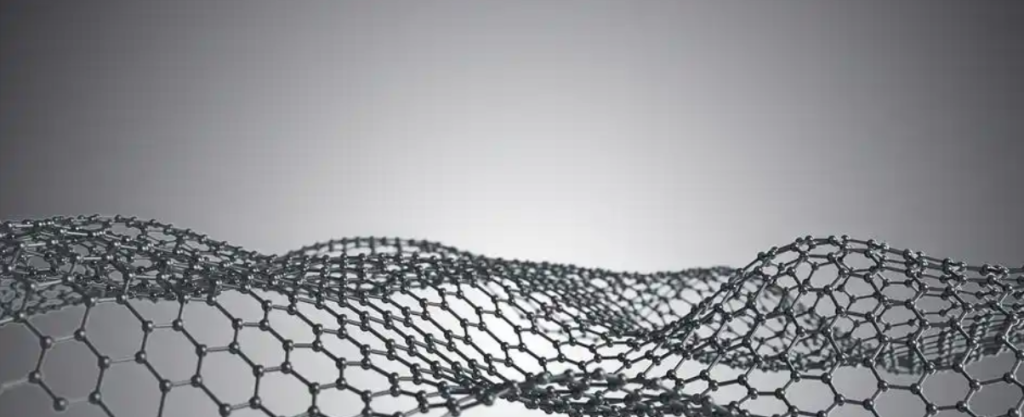

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. Its unique properties make it a powerful additive for infrastructure materials:

-

Strength: 200x stronger than steel.

-

Lightweight: adds durability without adding bulk.

-

Conductivity: enables smart monitoring and heating applications.

-

Chemical Resistance: protects against corrosion and environmental damage.

-

Sustainability: enhances material performance, reducing waste and extending lifespan.

When integrated into construction materials, graphene creates longer-lasting, smarter, and more sustainable infrastructure—perfectly aligned with the demands of high-speed rail.

Applications of Graphene in High-Speed Rail

1. Graphene-Enhanced Concrete

Concrete is the backbone of railways—used in foundations, bridges, tunnels, and track beds. Adding graphene improves:

-

Compressive and tensile strength, reducing cracking.

-

Water resistance, preventing damage from moisture and freeze–thaw cycles.

-

Durability, extending service life and reducing maintenance costs.

Some studies show up to 50% higher strength in graphene-enhanced concrete, meaning thinner, lighter structures with the same load-bearing capacity.

2. Track and Rail Components

Graphene-infused composites can replace or reinforce traditional steel components:

-

Graphene-polymer composites for rail fastenings and sleepers improve fatigue resistance.

-

Graphene coatings reduce friction and wear on rail surfaces, extending track lifespan.

3. Bridges and Tunnels

Large-scale rail structures suffer from vibration and corrosion. Graphene:

-

Strengthens bridge concrete against cracking.

-

Provides anti-corrosion coatings for steel reinforcements.

-

Enhances fire resistance in tunnels.

4. Energy Efficiency & Smart Heating

Graphene’s high electrical conductivity enables:

-

Self-heating tracks to prevent ice and snow accumulation in colder climates.

-

Energy-efficient de-icing systems integrated into switches and crossings.

5. Monitoring and Smart Infrastructure

Graphene-based sensors can be embedded into concrete and steel to:

-

Detect stress, strain, and cracking in real time.

-

Provide predictive maintenance data for rail operators.

-

Enhance safety by preventing catastrophic failures.

Benefits of Graphene in Rail Infrastructure

Extended Service Life

Graphene reduces wear, cracking, and corrosion, extending the lifespan of tracks, bridges, and tunnels by decades.

Reduced Maintenance Costs

Less frequent repairs and replacements lower operational expenses, saving governments and operators millions annually.

Improved Safety

Graphene-based coatings and sensors help detect early warning signs of damage, preventing accidents.

Sustainability and Green Construction

Longer-lasting infrastructure reduces the carbon footprint of repairs. Graphene also allows thinner material usage, lowering raw material demand.

Compatibility with High-Speed Travel

As trains get faster, rail materials must become stronger. Graphene provides the mechanical resilience and fatigue resistance needed for the next generation of HSR.

Case Studies and Research Highlights

-

Graphene Concrete in the UK: Researchers developed graphene-enhanced concrete with 35–50% increased compressive strength and reduced carbon footprint.

-

China’s Graphene Infrastructure Projects: Graphene coatings are being tested on bridges and rail systems to enhance durability.

-

European Union Initiatives: Graphene Flagship projects include trials of graphene composites in transport and infrastructure sectors.

Although still in early stages, these trials demonstrate the real-world potential of graphene in rail construction.

Market Potential

The global high-speed rail market is expected to surpass USD 200 billion by 2030, with rapid expansion in Asia, Europe, and North America. Infrastructure costs are massive, and governments are seeking long-lasting, low-maintenance solutions.

At the same time, the graphene market is projected to grow beyond USD 5 billion by 2032, with construction being a key application sector. The intersection of these two industries creates a significant commercial opportunity for graphene-enhanced materials in rail.

Challenges and Considerations

-

Cost of Graphene Production: Although prices are decreasing, large-scale infrastructure projects require affordable bulk graphene.

-

Standardization: Construction standards must evolve to include graphene composites.

-

Scalability: Ensuring consistent quality of graphene across tons of concrete and steel is complex.

-

Long-Term Testing: Infrastructure projects require proof of performance over decades, not just lab-scale tests.

Despite these hurdles, progress is accelerating as governments and companies invest in graphene pilot projects.

Future Outlook

The future of high-speed rail will rely heavily on advanced materials. Graphene is poised to play a central role by enabling:

-

Self-healing concrete using graphene-enhanced formulations.

-

Smart railways with embedded graphene sensors.

-

Lighter, stronger bridges that reduce costs and environmental impact.

-

Next-generation tracks with self-cleaning and anti-icing properties.

As production costs fall and adoption increases, graphene will shift from experimental use to mainstream infrastructure material in the coming decade.

High-speed rail is one of the most ambitious infrastructure investments of the 21st century. To meet the demands of speed, safety, durability, and sustainability, traditional materials are no longer enough.

Graphene-enhanced materials offer a breakthrough, providing stronger concrete, corrosion-resistant coatings, smart sensors, and energy-efficient heating solutions. While challenges remain in scaling and standardization, the trajectory is clear: graphene will be at the heart of future rail infrastructure.

For governments, investors, and construction companies, embracing graphene today means building rail systems that are safer, greener, and more cost-effective tomorrow.