CNTs in Portable Energy Harvesters: Powering the Next Generation of Wearable and Mobile Devices

The rapid rise of wearable electronics, Internet of Things (IoT) devices, and mobile gadgets has created an urgent demand for self-sustaining power sources. Batteries alone cannot keep up with the continuous miniaturization and 24/7 operation of these devices. This is where portable energy harvesters come into play.

Portable energy harvesters convert ambient energy—such as motion, light, heat, or radiofrequency signals—into usable electrical power. These devices can potentially eliminate the need for frequent recharging, enabling long-lasting, autonomous electronics.

To achieve high efficiency and flexibility, advanced materials are needed. Among them, carbon nanotubes (CNTs) stand out as a revolutionary enabler for next-generation energy harvesters. With their exceptional electrical, mechanical, and thermal properties, CNTs significantly enhance the performance, durability, and portability of energy-harvesting devices.

What Are Portable Energy Harvesters?

Portable energy harvesters are devices designed to capture small amounts of energy from the environment. Common mechanisms include:

-

Piezoelectric harvesters – generating electricity from vibrations or human motion.

-

Thermoelectric harvesters – converting body heat or waste heat into power.

-

Photovoltaic harvesters – small-scale solar panels for light-based energy capture.

-

Electromagnetic harvesters – using magnetic induction to generate electricity.

-

Triboelectric nanogenerators (TENGs) – converting mechanical friction into power.

Applications span from wearable health trackers and smartwatches to remote sensors, wireless communication nodes, and medical implants.

Why CNTs? The Material Advantage

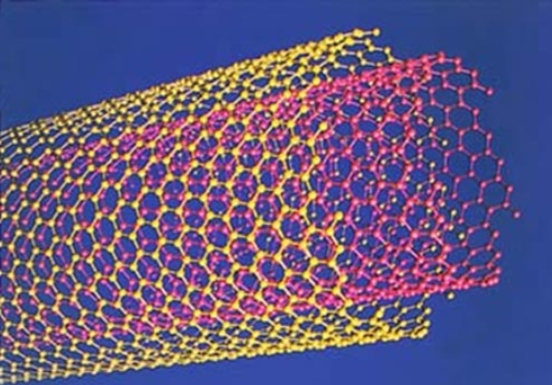

Carbon nanotubes are cylindrical structures made of rolled-up graphene sheets. Depending on their configuration (single-walled or multi-walled), CNTs can act as metallic conductors or semiconductors. Their unique combination of properties makes them ideal for energy harvesting:

-

High Electrical Conductivity – efficient charge transport.

-

Flexibility and Mechanical Strength – suitable for wearable and bendable devices.

-

Large Surface Area – improving interaction with external stimuli.

-

Thermal Conductivity – enabling better heat-to-electricity conversion.

-

Lightweight and Scalable – perfect for portable and compact systems.

By incorporating CNTs, researchers are developing energy harvesters that are lighter, more efficient, and highly durable.

How CNTs Enhance Different Energy Harvesting Mechanisms

1. CNTs in Piezoelectric and Triboelectric Nanogenerators

-

CNTs improve charge collection efficiency by providing conductive pathways.

-

Flexible CNT composites enhance the mechanical durability of wearable nanogenerators.

-

CNT electrodes in TENGs allow for ultra-thin, lightweight harvesters integrated into clothing or footwear.

2. CNTs in Thermoelectric Generators (TEGs)

-

CNT networks exhibit high Seebeck coefficients when properly doped, enabling efficient conversion of temperature gradients into electricity.

-

CNT composites improve flexible TEG performance, allowing energy harvesting from human body heat.

-

Applications: powering medical sensors or wearable devices without external charging.

3. CNTs in Photovoltaic Harvesters

-

CNT films can act as transparent conductive electrodes, replacing brittle ITO.

-

CNT/organic hybrid solar cells are lightweight, flexible, and printable, ideal for portable use.

-

CNTs enhance charge separation and transport, boosting photovoltaic efficiency in low-light conditions.

4. CNTs in Hybrid Harvesters

Many portable harvesters combine multiple mechanisms (e.g., solar + thermal + vibration). CNTs’ multifunctional role as conductors, structural reinforcements, and flexible substrates makes them a perfect fit for hybrid systems.

Applications of CNT-Enhanced Portable Energy Harvesters

Wearable Electronics

CNT-based harvesters integrated into smart clothing can capture motion and body heat, powering fitness trackers, smartwatches, or health monitors.

Healthcare and Medical Implants

Self-powered biosensors and implants reduce dependence on bulky batteries. CNT-enabled energy harvesters can generate electricity from body movement or heat, enhancing patient comfort and safety.

IoT and Remote Sensors

Wireless IoT devices in agriculture, logistics, or smart homes can operate autonomously with CNT-powered harvesters, avoiding battery replacement in hard-to-reach locations.

Military and Aerospace

Lightweight, flexible harvesters powered by CNTs can supply energy for soldier-worn electronics, drones, and satellites, where recharging is impractical.

Consumer Electronics

CNT-based portable solar harvesters or hybrid devices can charge phones, tablets, or wearables on the go, supporting outdoor and off-grid lifestyles.

CNTs vs. Other Nanomaterials in Energy Harvesters

-

Graphene: Excellent conductivity but lacks tubular geometry for strong 3D networks.

-

Metal Nanowires: Good conductors but prone to oxidation and mechanical breakage.

-

Conductive Polymers: Flexible but lower electrical performance and stability.

CNTs strike the best balance between conductivity, flexibility, and mechanical strength, making them ideal for multifunctional, durable harvesters.

Market Outlook

The global portable and wearable energy harvesting market is projected to exceed USD 5–6 billion by 2032, fueled by IoT expansion and consumer demand for self-powered devices. CNTs are expected to play a central role due to their:

-

Compatibility with flexible and stretchable electronics.

-

Potential for scalable production in coatings, films, and composites.

-

Ability to support miniaturized, multi-mechanism harvesters.

Major tech companies and startups are actively exploring CNT integration to create commercially viable portable harvesters.

Challenges and Considerations

-

Cost of High-Quality CNTs: Prices are falling, but large-scale production must be economical.

-

Dispersion Issues: Uniform CNT integration into polymers and composites is technically demanding.

-

Long-Term Durability: Wearable harvesters must endure repeated bending, washing, and environmental exposure.

-

Standardization and Certification: Industry-wide testing protocols are needed for commercialization.

Ongoing research is addressing these challenges, making CNT-enabled harvesters closer to widespread adoption.

Future Outlook

The future of portable energy harvesters with CNTs looks highly promising. Key trends include:

-

Printed CNT inks for scalable, roll-to-roll fabrication of flexible harvesters.

-

Hybrid CNT-based harvesters that combine solar, thermal, and kinetic energy collection.

-

Self-powered IoT ecosystems with CNT-enhanced nanogenerators embedded in everyday objects.

-

Smart clothing and wearables powered by CNT-based fabrics.

As CNT manufacturing scales and integration techniques improve, self-powered, portable electronics will become mainstream.

Portable energy harvesters represent the future of autonomous, battery-free electronics, and carbon nanotubes are at the heart of this transformation.

By enhancing conductivity, flexibility, and structural resilience, CNTs enable efficient and lightweight harvesters capable of capturing energy from motion, heat, and light. From wearables and medical devices to IoT and aerospace applications, CNT-enhanced harvesters promise longer-lasting, self-sustaining power solutions.

As research progresses and costs decline, CNTs will unlock a new generation of portable energy systems—helping society transition toward smarter, greener, and self-powered technologies.