CNTs in Advanced Thermal Insulation: A Nanomaterial Solution for Heat Management

As industries advance toward energy efficiency, sustainability, and high-performance engineering, thermal management has become a critical challenge. From aerospace and construction to electronics and energy systems, managing heat effectively determines both performance and safety. Traditional insulation materials such as fiberglass, foams, and ceramics have limitations in thermal stability, mechanical strength, and scalability.

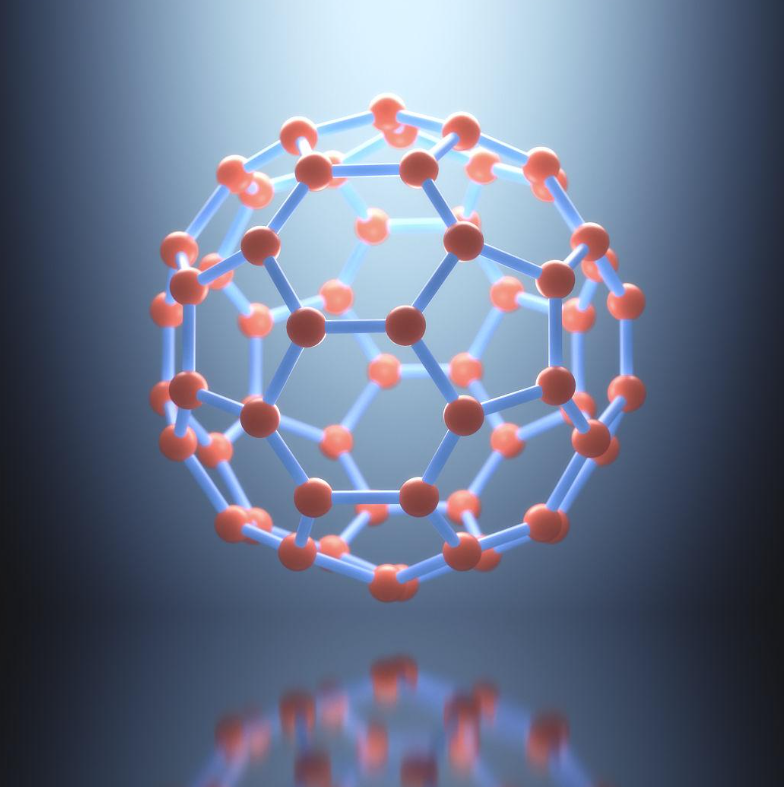

This is where carbon nanotubes (CNTs) come into play. With their unique nanostructure, low thermal conductivity in certain configurations, tunable properties, and outstanding mechanical strength, CNTs are emerging as a next-generation solution for advanced thermal insulation materials.

Why Carbon Nanotubes for Thermal Insulation?

CNTs are cylindrical nanostructures composed of rolled-up graphene sheets, and they provide multiple features beneficial to insulation:

-

Tunable Thermal Conductivity: While individual CNTs are highly conductive, their assemblies can be engineered to show ultra-low thermal conductivity due to phonon scattering.

-

High Aspect Ratio: Creates efficient barriers to heat transfer in composites.

-

Mechanical Strength: Adds durability and resilience to insulation systems.

-

Lightweight: Ideal for aerospace and portable applications.

-

Porous Structures: CNT aerogels and foams exhibit low density and strong insulating behavior.

This tunability makes CNTs unique—able to serve as both thermal conductors (for heat dissipation) and thermal insulators (for heat blocking), depending on their structural design.

Mechanisms of CNT-Based Thermal Insulation

1. Phonon Scattering

Heat conduction in CNT assemblies is primarily controlled by phonons (vibrations of the lattice). Disordered CNT networks, junctions, and defects create phonon scattering, reducing thermal conductivity.

2. Porosity and Low Density

CNT aerogels and foams are highly porous, trapping air within their structure. Since air is a poor conductor of heat, these materials exhibit exceptionally low thermal conductivity.

3. Composite Effects

When CNTs are embedded in polymers, ceramics, or hybrid nanostructures, they:

-

Create multi-scale barriers to heat flow.

-

Improve mechanical stability of insulation materials.

-

Allow customizable insulation properties through CNT alignment and dispersion.

Applications of CNTs in Advanced Thermal Insulation

1. Aerospace and Aviation

Aircraft and spacecraft require materials that can withstand extreme temperature fluctuations while remaining lightweight. CNT insulation materials:

-

Reduce thermal transfer in spacecraft hulls.

-

Protect sensitive instruments from heat damage.

-

Improve passenger comfort with lightweight insulation in cabins.

2. Construction and Architecture

Energy efficiency in buildings is a global priority. CNT composites can be incorporated into:

-

Insulating panels with superior strength and lower thickness.

-

Smart building materials that combine insulation with structural reinforcement.

-

Eco-friendly construction with longer lifetimes and reduced energy demand.

3. Electronics and Microdevices

As electronics shrink in size, heat management becomes critical. CNTs can act as:

-

Thermal barriers between components to prevent overheating.

-

Encapsulation materials protecting sensitive circuits.

-

Hybrid layers that combine insulation in one direction and heat conduction in another, optimizing device performance.

4. Energy Systems and Batteries

Batteries, fuel cells, and energy storage devices require insulation for both safety and efficiency. CNT insulation can:

-

Prevent thermal runaway in lithium-ion batteries.

-

Maintain stable temperatures in hydrogen storage and fuel cells.

-

Enable longer lifetimes for renewable energy systems.

5. Military and Protective Gear

CNT-based textiles and composites can serve as:

-

Heat-resistant fabrics for protective clothing.

-

Lightweight armor insulation, shielding soldiers from extreme environments.

Case Studies and Research Highlights

-

NASA Research: Explored CNT aerogels as thermal insulation for spacecraft, showing superior performance compared to silica aerogels.

-

MIT Studies: Demonstrated CNT-polymer composites with controllable thermal conductivity, enabling targeted insulation properties.

-

European Research Projects: Developed CNT-based construction materials with enhanced energy efficiency and durability.

-

Battery Research Groups: Incorporated CNT-based insulating layers to prevent overheating in high-density energy storage devices.

These advancements highlight CNTs’ potential as multi-functional insulation materials.

Benefits of CNT-Based Thermal Insulation

-

Ultra-Low Thermal Conductivity: Better performance than many traditional insulators.

-

Lightweight and Strong: Reduces load in aerospace and automotive applications.

-

Durability: Resistant to wear, cracking, and degradation.

-

Multifunctionality: Can combine thermal insulation with electrical conductivity, sensing, or structural strength.

-

Scalability Potential: CNTs can be formulated into foams, aerogels, coatings, or composites for diverse applications.

Market Potential

The global advanced insulation materials market is projected to exceed USD 15 billion by 2030, driven by aerospace, construction, and electronics.

Meanwhile, the carbon nanotube market is forecasted to reach USD 10+ billion by 2032, with growing applications in energy, electronics, and composites.

Integrating CNTs into insulation technologies positions them at the intersection of two rapidly expanding industries, offering strong commercial opportunities.

Challenges and Considerations

-

High Production Cost: CNTs remain more expensive than traditional insulation materials.

-

Uniform Dispersion: Achieving consistent CNT distribution in composites is difficult.

-

Standardization: Lack of established testing and certification methods for CNT insulation.

-

Scalability: Large-scale production of CNT aerogels and foams remains a challenge.

-

Environmental and Safety Concerns: Safe handling and disposal of CNT-based composites must be ensured.

Overcoming these hurdles will be essential for widespread adoption.

Future Outlook

The future of CNT-based insulation is promising, with research and industry pointing toward:

-

Next-Gen Aerospace Insulation: CNT aerogels replacing conventional silica aerogels.

-

Smart Insulation Materials: CNT composites that can self-monitor temperature and damage.

-

Hybrid Energy Systems: CNT insulation in batteries, fuel cells, and renewable power systems.

-

Sustainable Construction Materials: CNT-enhanced eco-friendly insulation for green buildings.

-

Mass-Market Consumer Applications: Incorporation into home appliances, clothing, and portable devices.

As production methods advance and costs decline, CNTs will likely become a mainstream choice for advanced thermal insulation materials.

Thermal insulation is vital for efficiency, safety, and sustainability across industries. Carbon nanotubes offer a groundbreaking approach, providing tunable thermal properties, mechanical strength, and multifunctionality unmatched by conventional materials.

From spacecraft and aircraft to green buildings, batteries, and protective gear, CNT-based insulation is set to transform how we manage heat in the modern world. While challenges remain in cost and scalability, ongoing research promises a future where CNTs redefine advanced thermal insulation, contributing to energy efficiency and sustainable innovation worldwide.