CNTs in Artificial Muscles: Powering the Future of Robotics and Biomedical Devices

Artificial muscles—engineered materials that mimic the function of biological muscles—are revolutionizing robotics, prosthetics, and biomedical engineering. Unlike traditional motors and actuators, artificial muscles offer lightweight, flexible, and biomimetic actuation, enabling machines and medical devices to interact more naturally with the human body.

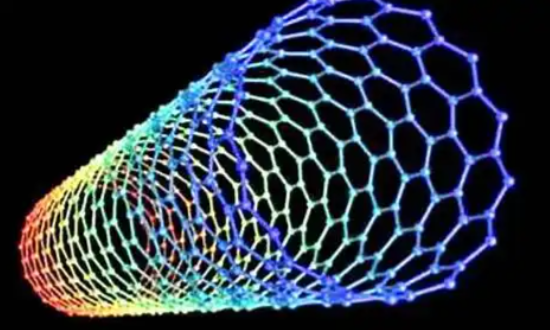

Among the many materials explored for artificial muscles, carbon nanotubes (CNTs) have emerged as one of the most promising candidates. Their combination of extraordinary strength, flexibility, electrical conductivity, and responsiveness to external stimuli makes CNTs highly suitable for next-generation artificial muscle systems.

Why Artificial Muscles Matter

Artificial muscles are critical for applications where conventional motors are too rigid, bulky, or inefficient. Key areas include:

-

Soft robotics → enabling robots that can move, grip, and interact like living organisms.

-

Medical prosthetics → providing natural movement to artificial limbs.

-

Wearable devices → integrating responsive materials into smart clothing.

-

Biomedical implants → powering minimally invasive devices inside the body.

-

Aerospace and defense → lightweight actuators for adaptive materials and systems.

However, current artificial muscle technologies—such as shape-memory alloys, dielectric elastomers, and conducting polymers—often face limitations in efficiency, fatigue resistance, or responsiveness. CNTs provide a potential solution.

Why CNTs for Artificial Muscles?

Carbon nanotubes possess unique physical and chemical properties that make them ideal for artificial muscles:

-

High Strength-to-Weight Ratio → CNTs are ~100x stronger than steel yet lighter.

-

Electrical Conductivity → CNTs act as efficient conductors for electrically driven actuation.

-

Thermal Conductivity → Rapid heat dissipation enables fast response times.

-

Flexibility → CNT sheets, yarns, and composites can bend and stretch without breaking.

-

Large Surface Area → Facilitates efficient charge storage and electrochemical reactions.

-

Electroactive Response → CNTs expand or contract when stimulated by voltage, heat, or chemical interactions.

These properties allow CNT-based materials to mimic the contraction and relaxation cycles of natural muscle tissue.

Mechanisms of CNT-Based Artificial Muscles

CNTs can function in different artificial muscle systems:

1. CNT Yarns and Fibers

-

Bundles of CNTs twisted into yarns can contract and expand when voltage is applied.

-

Provide high strength, fast actuation, and excellent fatigue resistance.

2. CNT Sheets and Films

-

Thin CNT layers expand or contract electrostatically when charged.

-

Useful for flat, lightweight actuators in robotics and biomedical devices.

3. CNT-Polymer Composites

-

CNTs embedded in elastomers or hydrogels provide electrically or thermally responsive actuation.

-

Enable flexible and stretchable artificial muscles.

4. Electrochemical CNT Actuators

-

CNT electrodes in electrolytes expand/contract with ion insertion and removal.

-

Provide high force output at low operating voltages.

5. Hybrid CNT Systems

-

CNTs combined with graphene, ionic liquids, or conductive polymers enhance efficiency and durability.

Applications of CNT-Based Artificial Muscles

1. Soft Robotics

-

CNT actuators power robots with smooth, biomimetic motion.

-

Useful for search-and-rescue robots, surgical robots, and adaptive grippers.

2. Medical Prosthetics

-

CNT artificial muscles enable lightweight prosthetic arms and legs with lifelike movement.

-

Improve comfort and mobility for amputees.

3. Wearable Technology

-

CNT fibers integrated into fabrics create responsive clothing that can adapt to temperature or movement.

-

Potential for military uniforms, smart textiles, and sports gear.

4. Biomedical Implants

-

CNT actuators can power micro-pumps for drug delivery, artificial valves, or neural stimulation devices.

-

Biocompatibility research shows promise for long-term medical use.

5. Aerospace and Defense

-

CNT muscles provide lightweight, adaptive materials for drones, morphing wings, and military robots.

-

High fatigue resistance ensures long-term reliability.

Case Studies and Research Highlights

-

University of Texas at Dallas: Developed CNT yarn muscles that contract 100x more than natural muscle, powered by voltage or chemical stimuli.

-

MIT: Created CNT-polymer composites with fast electrochemical actuation for biomedical applications.

-

Korea Advanced Institute of Science and Technology (KAIST): Designed CNT-based actuators with low energy consumption and high cycle stability.

-

NASA Research Teams: Exploring CNT actuators for lightweight aerospace applications, including deployable structures.

These studies demonstrate that CNT artificial muscles are not only a laboratory curiosity but are moving closer to real-world applications.

Advantages of CNT-Based Artificial Muscles

-

High Actuation Strain → Mimic or exceed the contraction of natural muscles.

-

Fast Response Time → Suitable for real-time robotics and prosthetics.

-

Durability → CNT yarns and composites withstand millions of cycles without degradation.

-

Lightweight → Reduce overall system mass in robotics, aerospace, and prosthetics.

-

Scalability → CNT fibers and films can be fabricated in large quantities.

-

Versatility → Function under electrical, thermal, or electrochemical stimulation.

Market Potential

The artificial muscle market is projected to grow significantly, reaching USD 3–4 billion by 2032, driven by robotics, healthcare, and defense applications.

The carbon nanotube market, valued at USD 2–3 billion by 2030, is expanding rapidly in electronics, composites, and biomedical fields.

CNT-based artificial muscles sit at the intersection of these two industries, with major growth opportunities in:

-

Medical prosthetics and implants.

-

Soft robotics for industry and healthcare.

-

Military and aerospace adaptive materials.

-

Smart textiles and wearable devices.

Challenges and Considerations

-

Cost of CNT Production – High-quality CNT fibers and films remain expensive.

-

Scalability – Large-scale, defect-free fabrication methods are still under development.

-

Energy Efficiency – Some CNT muscles require high voltages or complex electrolytes.

-

Biocompatibility and Safety – More research needed before CNT muscles can be implanted in humans.

-

Integration with Control Systems – Artificial muscles must work seamlessly with electronics and AI systems.

Future Look

The future of CNT artificial muscles looks promising, with key directions including:

-

Commercial CNT Prosthetics → providing lifelike motion for artificial limbs.

-

Soft Robotic Exoskeletons → powered by CNT actuators for rehabilitation and industry.

-

Wearable CNT Fabrics → adaptive uniforms and smart clothing.

-

Medical Micro-Actuators → CNT-driven devices for drug delivery and minimally invasive surgery.

-

Aerospace Deployables → CNT muscles enabling lightweight morphing wings and adaptive spacecraft structures.

As CNT manufacturing costs fall and integration improves, CNT artificial muscles will transition from labs to commercial and medical markets, shaping the future of biomimetic robotics and healthcare technology.

Carbon nanotubes (CNTs) are redefining the field of artificial muscles. With their unmatched strength, conductivity, and responsiveness, CNT-based actuators offer significant improvements over traditional artificial muscle technologies. They are lightweight, durable, and scalable, making them ideal for robotics, prosthetics, aerospace, and biomedical applications.

From soft robots that move like living organisms to prosthetics that restore natural mobility, CNT artificial muscles represent a major leap forward in engineering and healthcare. While challenges remain in cost, scalability, and biocompatibility, ongoing research indicates that CNT actuators will become an essential component of next-generation robotic and medical systems.