Reduced Graphene Oxide in Flexible Electronics: Replacing ITO for the Next Generation of Devices

The rise of flexible electronics is transforming modern technology — from wearable health trackers to foldable smartphones and bendable displays. At the heart of this revolution lies the need for materials that are transparent, conductive, lightweight, and mechanically flexible.

For decades, Indium Tin Oxide (ITO) has been the dominant transparent conductor in displays and touch panels. However, ITO’s brittleness, high cost, and dependence on scarce indium resources make it unsustainable for flexible applications.

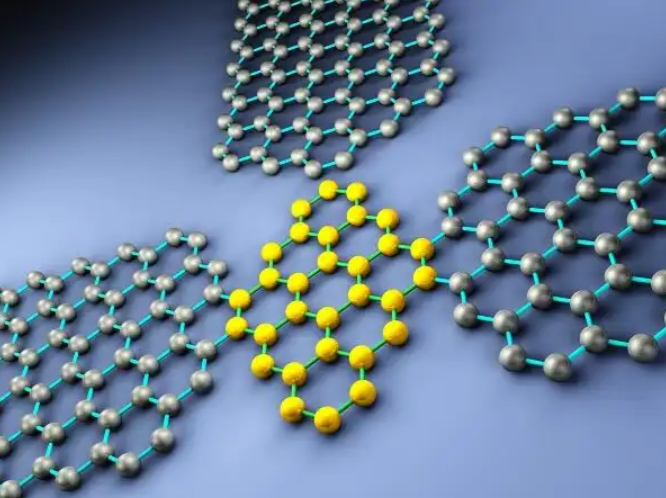

This is where Reduced Graphene Oxide (rGO) comes into play. Derived from graphene oxide (GO) through various reduction processes, rGO offers conductivity, transparency, and flexibility — key traits for the next generation of flexible electronic devices.

What is Reduced Graphene Oxide (rGO)?

Graphene oxide (GO) is a chemically modified form of graphene that contains oxygen functional groups (–OH, –COOH, –O–). While GO is insulating, these functional groups allow it to be easily dispersed in water and processed into thin films.

By removing oxygen-containing groups through reduction (chemical, thermal, or electrochemical), GO transforms into reduced graphene oxide (rGO). This process partially restores the sp² carbon network, leading to improved electrical conductivity and mechanical integrity.

Key Properties of rGO:

-

Good electrical conductivity (though lower than pristine graphene)

-

Mechanical flexibility and robustness

-

Optical transparency (70–90% depending on thickness)

-

Scalable and low-cost fabrication

These advantages make rGO one of the most promising candidates for conductive films in flexible electronics.

Why rGO is Suitable for Flexible Electronics

1. Excellent Conductivity

Reduction processes restore the delocalized π-electron system in graphene, enabling efficient electron transport. rGO films can achieve sheet resistances as low as a few hundred ohms per square, sufficient for electrodes and circuits in flexible devices.

2. Mechanical Flexibility

Unlike brittle ITO, rGO films remain conductive even after repeated bending or stretching, an essential property for wearable and foldable electronics.

3. Transparency

Thin rGO layers maintain high optical transparency, making them suitable for touchscreens, displays, and solar cells.

4. Scalable Fabrication

rGO can be produced through printing, spray-coating, spin-coating, or roll-to-roll processing, allowing easy integration with existing electronic manufacturing lines.

5. Cost and Sustainability

rGO is derived from carbon — abundant, inexpensive, and eco-friendly — providing a sustainable alternative to rare-metal-based ITO.

Applications of rGO in Flexible Electronics

1. Wearable Devices

rGO-based conductive films are used in wearable sensors, smart textiles, and electronic skins to measure physiological signals such as heart rate, temperature, and movement.

-

Example: rGO-coated fabrics function as stretchable conductors for real-time health monitoring.

2. Flexible Displays and Touchscreens

rGO transparent electrodes can replace ITO in OLED and LCD panels, offering durability and flexibility for foldable and rollable screens.

-

Example: Hybrid rGO films with silver nanowires achieve both high conductivity and optical clarity.

3. Printed Flexible Circuits

rGO inks can be printed directly onto polymer or paper substrates to create lightweight, low-cost circuits — ideal for disposable electronics and IoT sensors.

4. Energy Storage Components

In flexible batteries and supercapacitors, rGO serves as a conductive electrode material due to its high surface area and charge mobility.

5. Biomedical Sensors

rGO’s biocompatibility and conductivity enable applications in biosensors and implantable devices, bridging electronics with biological systems.

rGO vs. ITO: A Clear Comparison

| Property | Indium Tin Oxide (ITO) | Reduced Graphene Oxide (rGO) |

|---|---|---|

| Conductivity | Excellent | Moderate to High (tunable) |

| Transparency | Excellent | Good (thickness-dependent) |

| Flexibility | Poor (brittle) | Excellent |

| Cost | Expensive (indium-based) | Low (carbon-based) |

| Processability | Limited | Printable, scalable |

| Environmental Impact | High | Low, sustainable |

While ITO remains the industry standard for rigid electronics, rGO’s superior flexibility and cost advantages make it ideal for next-generation flexible devices.

Technical Advances in rGO Fabrication

-

Chemical Reduction

-

Using agents like hydrazine or ascorbic acid to remove oxygen groups.

-

Produces rGO with moderate conductivity and high flexibility.

-

-

Thermal Reduction

-

High-temperature annealing restores more sp² bonds, improving conductivity.

-

Best suited for substrates that can withstand heat.

-

-

Electrochemical Reduction

-

Environmentally friendly and precise control over reduction level.

-

-

Hybrid rGO Composites

-

Combining rGO with metal nanowires, conductive polymers, or CNTs to further enhance conductivity and performance.

-

Challenges and Limitations

-

Incomplete Restoration of Conductivity

-

rGO’s conductivity is lower than pristine graphene; additional doping or hybridization is often required.

-

-

Transparency vs. Conductivity Trade-Off

-

Increasing thickness improves conductivity but reduces optical transparency.

-

-

Film Uniformity

-

Achieving consistent large-area films remains a technical challenge for industrial use.

-

-

Interface Engineering

-

Integration with other materials (e.g., polymers, metals) requires careful control to ensure adhesion and stability.

-

Future Directions

The next decade will likely see rGO transition from lab-scale innovation to commercial adoption in flexible electronics. Key trends include:

-

Hybrid Conductive Films: Combining rGO with silver nanowires, conductive polymers, or carbon nanotubes.

-

Eco-Friendly Production: Using green reduction agents (e.g., vitamin C, plant extracts).

-

Mass Production Techniques: Roll-to-roll and inkjet printing for large-scale device manufacturing.

-

Integration into IoT Devices: Ultra-light, low-cost rGO circuits powering flexible sensors and displays.

Reduced Graphene Oxide (rGO) stands as a key enabler for the future of flexible electronics. With its excellent conductivity, transparency, mechanical flexibility, and scalability, rGO is emerging as a viable alternative to traditional ITO in wearable devices, flexible displays, and printed circuits.

While challenges remain — particularly in improving conductivity and large-area uniformity — rapid advancements in synthesis and hybrid materials are accelerating rGO’s path toward commercialization.

As flexible and wearable electronics become mainstream, rGO-based conductive films will play a central role in creating devices that are not only smarter and thinner, but also greener and more sustainable.