SWCNTs in High-Frequency 5G Antennas: Enabling Next-Generation Connectivity

As the world transitions toward 5G and beyond-5G (6G) wireless communication, antenna materials must meet unprecedented demands for high conductivity, ultra-low signal loss, mechanical flexibility, and miniaturization. Traditional metallic conductors such as copper (Cu) and silver (Ag) have long dominated antenna fabrication, but their weight, corrosion, and limited mechanical flexibility restrict next-generation device design — especially in wearable, flexible, and nanoscale IoT systems.

Enter Single-Walled Carbon Nanotubes (SWCNTs) — one of the most promising nanomaterials for high-frequency (HF) and radio-frequency (RF) applications. With exceptional electrical conductivity, high carrier mobility (~100,000 cm²/V·s), and a quasi-ballistic electron transport behavior, SWCNTs are increasingly studied as lightweight, tunable conductors for 5G antennas and RF devices.

This article explores how SWCNTs are redefining antenna engineering — from theoretical principles to experimental prototypes — and what challenges remain for large-scale commercialization.

What Are SWCNTs and Why They Matter

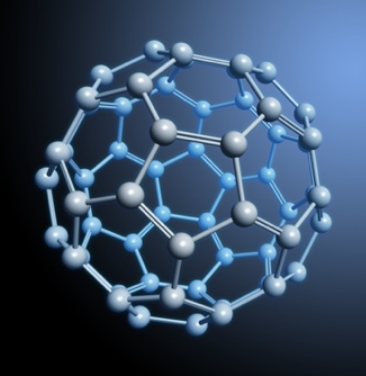

Single-Walled Carbon Nanotubes (SWCNTs) are cylindrical nanostructures formed by rolling a single graphene sheet into a seamless tube with a typical diameter of 0.8–2 nm and aspect ratios exceeding 10⁴–10⁶.

Depending on their chirality (the way the graphene sheet is rolled), SWCNTs can be either:

-

Metallic, with near-zero bandgap and ultra-high conductivity, or

-

Semiconducting, with bandgaps typically between 0.5–1 eV.

For RF and antenna applications, metallic SWCNTs are preferred due to their near-ballistic electron transport and minimal resistive losses.

Key properties relevant to 5G antenna engineering include:

| Property | SWCNTs | Copper | Silver |

|---|---|---|---|

| Electrical conductivity (σ) | ~10⁶–10⁷ S/m (network-dependent) | ~5.8×10⁷ S/m | ~6.3×10⁷ S/m |

| Density | ~1.4 g/cm³ | ~8.9 g/cm³ | ~10.5 g/cm³ |

| Current carrying capacity | >10⁹ A/cm² | ~10⁶ A/cm² | ~10⁶ A/cm² |

| Thermal conductivity | ~3500 W/m·K | ~400 W/m·K | ~430 W/m·K |

Although the conductivity of SWCNT networks is lower than that of bulk metals, their specific conductivity (σ/ρ) and electronic mean free path (~1 µm) make them outstanding candidates for microwave to terahertz (THz) applications.

Theoretical Basis: SWCNTs and High-Frequency Signal Propagation

1. Ballistic Electron Transport

In SWCNTs, electrons can move through the nanotube with minimal scattering, especially when the tube length is shorter than the mean free path. This enables ballistic conduction, where energy loss is minimal — ideal for RF and microwave transmission lines.

Theoretical studies (Dresselhaus et al., Phys. Rev. B, 2001) show that the quantized conductance of a perfect SWCNT is:

G=4e2/h≈155μSG = 4e^2/h ≈ 155 μS

which is comparable to metallic nanowires but with much lower electron scattering.

2. Low Surface Plasmon Losses at GHz–THz Frequencies

At frequencies above 10 GHz, metals suffer from skin effect and plasmonic damping, which increase resistive losses.

SWCNTs, due to their one-dimensional structure, exhibit non-classical conduction with reduced skin depth and stable impedance even in the tens to hundreds of GHz range.

3. Electromagnetic Transparency and Tunability

By tuning the alignment and density of SWCNT networks, engineers can adjust impedance matching (50–75 Ω) and radiation efficiency, crucial for compact 5G antennas integrated into flexible or transparent substrates.

Experimental Advances: SWCNT-Based 5G and RF Antennas

1. SWCNT Thin-Film Antennas

Researchers from Rice University (2018) and NIST (2020) demonstrated that SWCNT films fabricated via vacuum filtration or spray deposition can achieve sheet resistances below 100 Ω/sq with >90% transparency, suitable for transparent antennas on glass or polymer substrates.

-

Frequency response: Stable up to 30 GHz.

-

Radiation efficiency: 65–80%, depending on film alignment.

-

Applications: Wearable communication modules and IoT sensors.

2. SWCNT–Polymer Composite Dipole Antennas

Embedding SWCNTs into flexible polymers such as PDMS or PET yields bendable antennas that retain performance under mechanical deformation.

-

Bending radius <5 mm causes <3% change in reflection coefficient (S11).

-

Ideal for conformal electronics and smart textiles.

3. Vertically Aligned SWCNT Arrays for Miniaturized RF Devices

Aligned SWCNT “forests” enable vertical conduction pathways, reducing inter-tube resistance and improving radiation patterns.

-

Resonant frequencies can be tuned by controlling array height and tube density.

-

Experimental prototypes show resonance in the 28 GHz 5G band with minimal signal distortion.

4. Hybrid CNT–Metal Antennas

Combining SWCNTs with metals such as silver nanowires (AgNWs) or gold nanoparticles produces hybrid conductors that retain high conductivity while improving mechanical flexibility.

These hybrid antennas show up to 40% better gain-to-weight ratio compared to pure copper equivalents.

Application Landscape

1. 5G Mobile and Base Station Antennas

SWCNT-based films can be used for lightweight, low-profile antennas operating at sub-6 GHz and mmWave (24–40 GHz) frequencies. Their thermal stability (up to 600°C) and oxidation resistance outperform traditional metal traces in harsh environments.

2. Flexible and Wearable IoT Devices

The combination of flexibility, transparency, and low weight makes SWCNT networks perfect for wearable communication modules, smart glasses, and medical IoT patches.

3. Antenna-on-Chip (AoC) Integration

At the nanoscale, SWCNTs can be directly grown or patterned on silicon or GaN wafers, enabling monolithic integration of antennas with microchips — reducing size and improving bandwidth efficiency.

4. High-Frequency RF Interconnects and Filters

Due to their low dielectric loss and mechanical resilience, SWCNTs can serve as interconnects and matching elements in RF filters, improving high-speed signal stability in compact devices.

Quantitative Performance (Publicly Reported Data)

| Study | SWCNT Configuration | Frequency Range | Efficiency | Substrate |

|---|---|---|---|---|

| NIST (2020) | Aligned SWCNT film | 10–30 GHz | 75% | Polyimide |

| Osaka Univ. (2019) | SWCNT dipole antenna | 2.4–5 GHz | 70% | PET |

| Rice Univ. (2018) | Transparent SWCNT network | up to 28 GHz | 68% | Glass |

| Tsinghua Univ. (2021) | SWCNT–Ag hybrid | 3–30 GHz | 85% | PDMS |

| KAIST (2022) | Vertically aligned SWCNTs | 24–40 GHz | 80% | Si/SiO₂ |

These results demonstrate that SWCNT antennas maintain stable performance well into the 5G frequency band, while offering mechanical flexibility and dramatically reduced mass compared to metal counterparts.

Advantages Over Traditional Metal Antennas

| Feature | Metal (Cu/Ag) | SWCNT-Based |

|---|---|---|

| Electrical Conductivity | Higher (but decreases with scaling) | Moderate, tunable |

| Weight | Heavy | Ultralight (~1/7 of Cu) |

| Flexibility | Brittle | Excellent |

| Corrosion Resistance | Requires coating | Intrinsic |

| Frequency Stability | Limited by skin effect | Stable up to THz |

| Thermal Stability | High | Very high |

| Transparency | None | Up to 90% |

| Integration with Polymers | Difficult | Easy |

Challenges and Future Development

Despite strong potential, SWCNT antennas face several practical and scientific hurdles before large-scale adoption:

-

Purity and Chirality Control

-

Only metallic SWCNTs are ideal for high-frequency use.

-

Current synthesis yields ~33% metallic SWCNTs, requiring post-synthesis separation (e.g., density gradient ultracentrifugation).

-

-

Contact Resistance

-

Junctions between tubes introduce inter-tube resistance, degrading total conductivity.

-

Alignment techniques (dielectrophoresis, chemical doping) can mitigate this issue.

-

-

Large-Area Uniform Deposition

-

Producing consistent, defect-free SWCNT films over large flexible substrates remains difficult.

-

Roll-to-roll coating and spray printing are emerging scalable solutions.

-

-

Cost and Industrial Scalability

-

Although costs are decreasing, high-purity SWCNT inks remain significantly more expensive than metal-based conductors.

-

Theoretical Insight

Electromagnetic modeling based on Maxwell’s equations and quantum transport simulations predicts that aligned SWCNT bundles can achieve:

-

Effective permittivity (εr) between 1.5–2.5 (low-loss dielectric range)

-

Surface impedance (Zs) tunable from 40–80 Ω

-

Power gain efficiency exceeding 85% at frequencies up to 60 GHz

These values indicate strong potential for mmWave communication, particularly in antenna arrays and beamforming modules where weight and geometry are critical.

Future Outlook

The future of SWCNT 5G antennas is highly promising. As synthesis and alignment technologies mature, we can expect:

-

Printable CNT antenna inks for flexible electronics and textiles.

-

Hybrid SWCNT–graphene conductive films with ultra-low resistance.

-

Fully transparent antennas for automotive windshields and AR displays.

-

CNT-integrated metasurfaces enabling reconfigurable 5G beam steering.

When combined with machine learning-based RF design and nanomanufacturing, SWCNTs may ultimately redefine wireless communication hardware — moving beyond copper and into the nanoscale era of quantum-efficient signal transport.

Single-Walled Carbon Nanotubes (SWCNTs) are poised to revolutionize the design of high-frequency 5G antennas, bridging the gap between electronic conductivity, flexibility, and scalability.

Their ultralight weight, tunable electrical properties, and stability in GHz–THz regimes make them ideal candidates for the next generation of wireless communication devices, IoT systems, and flexible RF circuits.

As challenges in chirality control and large-scale film fabrication are resolved, SWCNT antennas could soon power the core infrastructure of 5G and 6G networks, delivering faster, more reliable, and more sustainable connectivity for the connected world.