Graphene Oxide in High-Performance Coatings and Paints

How GO Enhances Durability, Corrosion Resistance, and Fire Protection

In industries where durability, corrosion resistance, and surface protection are critical — such as construction, automotive, and marine — coatings play a vital role in extending product lifespan and safety. However, traditional coatings often struggle to balance mechanical strength, chemical resistance, and environmental performance.

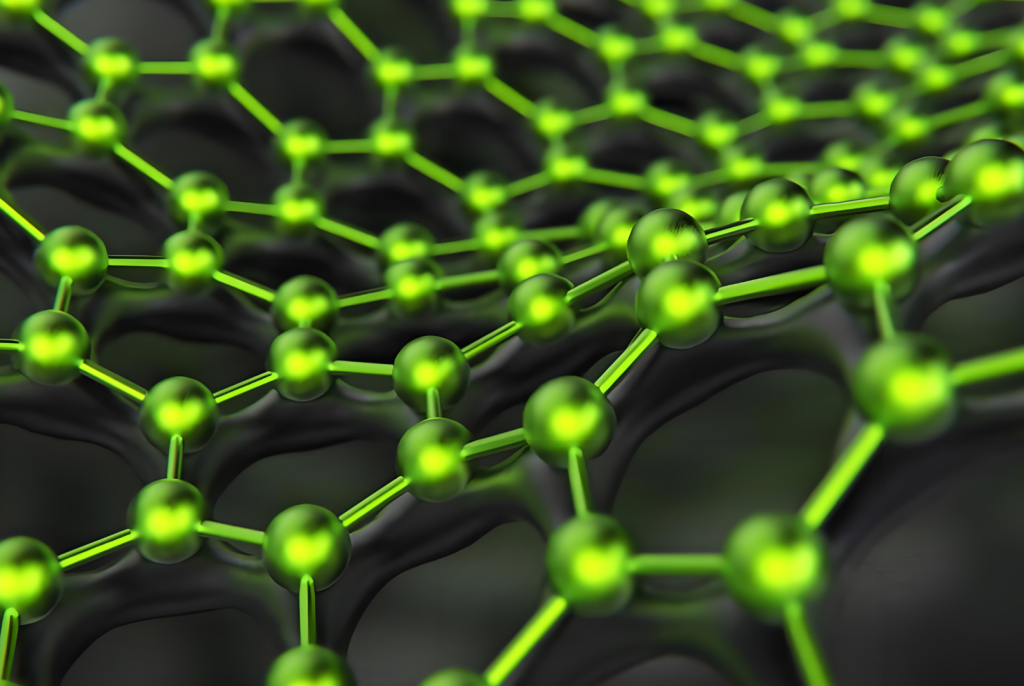

Enter Graphene Oxide (GO) — a derivative of graphene that combines exceptional barrier properties with chemical versatility. Its two-dimensional structure, decorated with oxygen-containing functional groups, enables strong bonding with polymers, resins, and inorganic matrices.

This unique hybrid nature makes GO an ideal additive for high-performance coatings and paints, capable of transforming ordinary surfaces into anti-corrosive, flame-retardant, and mechanically robust materials.

What Makes Graphene Oxide Unique for Coatings?

Graphene oxide consists of a single-atom-thick carbon sheet functionalized with epoxy, hydroxyl, and carboxyl groups. These oxygen groups serve two crucial purposes:

-

Improve dispersibility in polar solvents and coating resins.

-

Enable chemical bonding with organic polymers and inorganic binders.

| Property | Typical Value | Benefit for Coatings |

|---|---|---|

| Sheet thickness | ~1 nm | Ultrathin, uniform barrier layer |

| Aspect ratio | >1000 | Excellent surface coverage |

| Young’s modulus | ~200 GPa | High mechanical strength |

| Thermal stability | Up to 500°C | Enhances fire resistance |

| Electrical conductivity | Tunable (insulating to semiconducting) | Customizable coating behavior |

In comparison with pristine graphene, GO offers easier processing and better compatibility with commercial coating systems — making it the preferred choice for scalable industrial applications.

1. Anti-Corrosion Coatings with GO

The Problem

Corrosion costs industries over $2.5 trillion annually, affecting pipelines, ships, bridges, and vehicles. Conventional anti-corrosion coatings rely on heavy metals (like zinc) or organic inhibitors, which face environmental and regulatory challenges.

The GO Solution

GO acts as a physical barrier that prevents moisture, oxygen, and chloride ions from reaching the metal substrate. Its layered structure significantly increases the diffusion path length for corrosive species — a phenomenon known as the “tortuous path effect.”

When GO is dispersed in epoxy or polyurethane coatings:

-

It reduces the water permeability by 70–90%.

-

It delays the onset of corrosion in salt spray tests by up to 10×.

-

It improves adhesion strength through hydrogen bonding and van der Waals interactions.

A study from the University of Manchester reported that only 0.5 wt% GO in epoxy coatings reduced corrosion current density by 95% compared to pure epoxy.

Typical Applications:

-

Ship hull coatings

-

Bridge and offshore platform protection

-

Automotive underbody paints

-

Steel storage tanks and pipelines

2. Fire-Resistant and Flame-Retardant Coatings

Why GO Works

GO’s carbon-based nanosheets form a thermally stable char layer under high heat. This layer:

-

Reflects radiant heat,

-

Insulates the underlying material, and

-

Prevents oxygen diffusion to the combustion zone.

Furthermore, GO can interact with phosphorus or silicon flame retardants, forming a synergistic network that enhances fire suppression while reducing smoke generation.

Performance Data

-

Epoxy-GO composites can withstand temperature exposure up to 500°C before significant degradation.

-

Flame spread tests show 30–40% reduction in peak heat release rates.

-

GO-modified coatings maintain structural integrity after flame tests where conventional paints blister or char completely.

Applications:

-

Building steel structures and façades

-

Fireproof coatings for vehicles and aircraft interiors

-

Cable insulation and electrical panels

3. Mechanical Reinforcement and Wear Resistance

Beyond barrier effects, GO enhances mechanical robustness of coatings. Its nanoplatelet structure distributes mechanical stress efficiently, improving:

-

Scratch resistance

-

Tensile strength

-

Abrasion resistance

For example, polyurethane coatings with 1 wt% GO showed a 60% increase in tensile strength and 45% reduction in wear rate under friction testing.

In automotive and aerospace coatings, such improvements translate to:

-

Longer-lasting protective layers

-

Reduced maintenance frequency

-

Better protection against particulate erosion and impact

4. Hydrophobic and Self-Cleaning Surfaces

When GO is partially reduced to rGO (reduced graphene oxide), it becomes hydrophobic due to decreased oxygen content and restored π-conjugation. This results in coatings that:

-

Repel water and dust

-

Prevent microbial and biofouling adhesion

-

Maintain optical clarity in transparent systems

Hydrophobic coatings with rGO achieve water contact angles >120°, demonstrating strong self-cleaning performance on glass, metal, and plastic surfaces.

These properties are particularly valuable in:

-

Architectural façades

-

Solar panel coatings

-

Marine vessel exteriors

5. Multifunctional Synergy in Hybrid Coatings

One of GO’s greatest strengths lies in its compatibility with other additives:

-

With ZnO or TiO₂: enhances UV protection and photocatalytic degradation of pollutants.

-

With polymeric resins: increases flexibility and adhesion strength.

-

With metal oxides: boosts anti-corrosion and antibacterial performance.

This versatility allows GO-based coatings to function as smart surfaces — simultaneously protecting, cleaning, and even sensing environmental conditions.

6. Real-World Applications and Industrial Use

Construction and Infrastructure

GO-enhanced paints are being tested for bridges, wind turbines, and high-rise façades. Their anti-corrosion and UV resistance prolong maintenance intervals in harsh climates.

Automotive Industry

Manufacturers explore GO-polyurethane coatings for:

-

Scratch-resistant clear coats

-

Heat-dissipating body panels

-

Lightweight corrosion barriers

Marine and Offshore

Ships and oil platforms benefit from GO’s resistance to saltwater corrosion and biofouling. When combined with anti-fouling polymers, GO-based coatings extend service intervals from 3 years to over 6 years.

Aerospace and Defense

GO composites provide both flame retardancy and mechanical reinforcement, reducing weight while maintaining thermal protection for structural components.

7. Challenges and Optimization

While the benefits are clear, a few challenges remain before large-scale deployment:

| Challenge | Description | Possible Solution |

|---|---|---|

| Dispersion Stability | GO tends to agglomerate in polymer matrices. | Use surfactants or functionalization with silane/amine groups. |

| Cost and Scalability | High-purity GO is expensive to produce. | Adopt scalable oxidation–reduction or electrochemical synthesis methods. |

| Long-Term Environmental Stability | UV exposure may reduce GO, altering properties. | Apply UV absorbers or multi-layer barrier systems. |

| Compatibility with Industrial Paint Systems | Need optimized viscosity and curing behavior. | Formulate hybrid epoxy or acrylic resins. |

As production technologies improve, these limitations are rapidly being addressed through green synthesis routes and optimized nanocomposite formulations.

8. The Future of GO Coatings

The next generation of graphene oxide coatings will integrate additional functionalities, such as:

-

Self-healing mechanisms (via polymer-GO ionic bonding)

-

Electrostatic shielding and EMI protection

-

Embedded sensing for structural health monitoring

Moreover, with increasing environmental regulations, GO-based non-toxic coatings offer a sustainable alternative to chromium- and lead-based systems.

The global graphene coatings market is projected to exceed USD 1.8 billion by 2032, driven by rapid adoption in construction, automotive, and marine sectors.

Graphene oxide has redefined the possibilities of protective coatings. Its unique ability to combine chemical resistance, mechanical strength, and thermal stability enables the creation of multifunctional, long-lasting surfaces across industries.

From ship hulls to skyscraper façades, GO-based coatings are paving the way toward greener, safer, and more durable materials. With ongoing progress in scalable production and composite design, GO will soon become a standard additive in high-performance paints and coatings worldwide.

In essence, graphene oxide doesn’t just protect surfaces — it elevates them to a new standard of performance.