SWCNTs in Smart Textiles for Energy Harvesting

How Carbon Nanotubes Are Powering the Future of Wearable Electronics

As wearable technology becomes a defining element of the modern lifestyle, the demand for lightweight, flexible, and self-powered fabrics is rapidly increasing. From fitness trackers woven into clothing to medical sensors that monitor vital signs, these innovations depend on one key challenge — finding reliable, integrated power sources.

Traditional batteries are bulky and inflexible, limiting textile comfort and wearability. This is where Single-Walled Carbon Nanotubes (SWCNTs) step in. Their exceptional electrical conductivity, mechanical strength, and nanoscale flexibility make them the ideal material for energy-harvesting smart textiles that can both generate and store energy.

SWCNTs are not just passive materials; they act as the nervous system of smart fabrics, enabling power generation, sensing, and energy storage — all within fibers thinner than a human hair.

Why SWCNTs Are Perfect for Smart Textiles

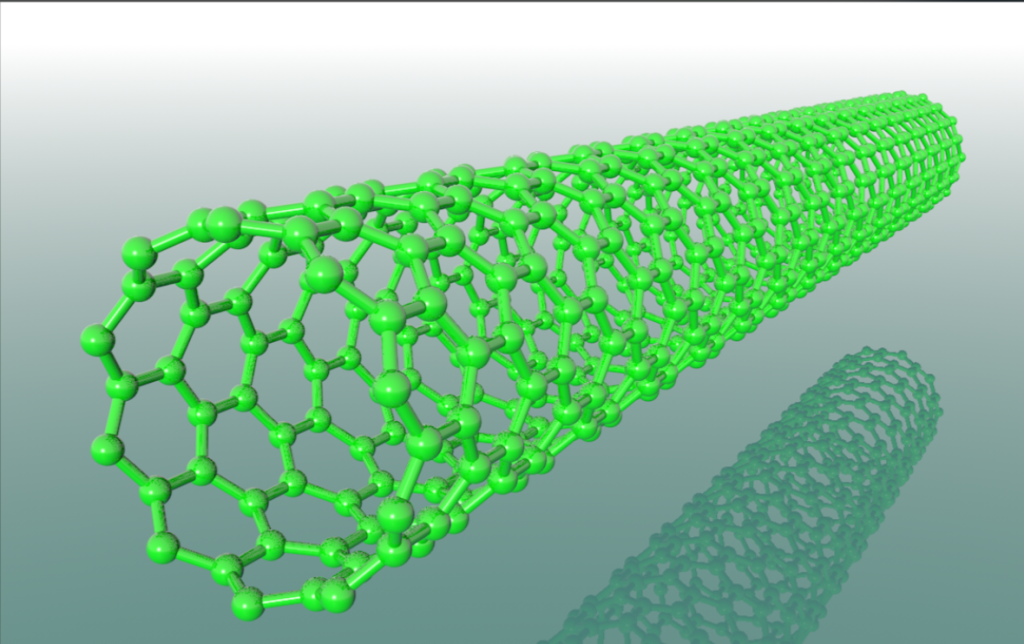

Single-Walled Carbon Nanotubes (SWCNTs) are cylindrical nanostructures composed of a single layer of graphene rolled into a seamless tube. Their one-dimensional geometry gives them several unique advantages for textile integration:

| Property | Typical Value | Textile Benefit |

|---|---|---|

| Electrical conductivity | up to 10⁶ S/m | Enables current flow through fibers |

| Tensile strength | ~100 GPa | Prevents damage under repeated bending |

| Flexibility | Can bend thousands of times without fatigue | Perfect for woven structures |

| Thermal conductivity | up to 3500 W/m·K | Efficient heat dissipation during operation |

| Density | ~1.3 g/cm³ | Lightweight, suitable for wearable comfort |

These properties allow SWCNTs to be woven, coated, or printed onto traditional fabrics (like cotton, nylon, or polyester) to create conductive, energy-active surfaces.

1. SWCNTs as Conductive Networks in Smart Fabrics

The Concept

By embedding SWCNTs into textile fibers, researchers can turn ordinary fabrics into conductive networks capable of transferring electric signals and powering small devices.

This can be achieved by:

-

Coating natural fibers with SWCNT ink or dispersion;

-

Spinning SWCNT/polymer composite yarns;

-

Printing SWCNT circuits directly onto fabrics using inkjet or screen printing.

Performance

-

Sheet resistivity as low as 10 Ω/sq has been achieved on SWCNT-coated fabrics.

-

Electrical conductivity remains stable after 10,000 bending cycles.

-

Fabrics retain over 90% of their mechanical flexibility and breathability.

These conductive networks form the foundation for energy-harvesting and storage layers, transforming passive fabrics into multifunctional electronic systems.

2. Energy Harvesting Mechanisms with SWCNTs

Smart textiles using SWCNTs can harvest ambient energy from multiple sources — mechanical motion, body heat, and even sunlight. The key mechanisms include:

(a) Triboelectric Nanogenerators (TENGs)

When fabrics rub against skin or other textiles, they generate charge through friction (triboelectric effect).

SWCNTs, due to their conductivity and high surface area, enhance charge collection and transfer efficiency.

-

Power density: up to 20–50 μW/cm² in prototype SWCNT TENG fabrics.

-

Output remains stable under repetitive motion such as walking or arm movement.

Applications:

Powering health monitors, motion sensors, or small LEDs in clothing.

(b) Thermoelectric Generators (TEGs)

SWCNTs exhibit tunable Seebeck coefficients and can form efficient thermoelectric composites. When a temperature gradient exists between the body and ambient air, these materials convert it into electricity.

-

Seebeck coefficient: up to 60–80 μV/K (depending on doping).

-

Power factor: ~120 μW/m·K² for SWCNT/polymer composites.

Applications:

Continuous power generation from body heat for smart watches or biometric sensors.

(c) Solar Energy Harvesting Textiles

SWCNTs can serve as transparent conductive electrodes in fiber-shaped or fabric-integrated solar cells.

When combined with perovskite or organic photovoltaic layers, they provide:

-

High flexibility,

-

Excellent light absorption, and

-

Stable conductivity under strain.

A study from MIT demonstrated a flexible SWCNT–polymer solar textile achieving ~4.5% power conversion efficiency while maintaining fabric softness.

Applications:

Outdoor gear and military uniforms that recharge portable electronics via sunlight.

3. Energy Storage with SWCNT-Integrated Fabrics

Harvesting energy is only half the solution — storing it efficiently is equally critical.

SWCNTs can be incorporated into fabrics as electrodes for flexible supercapacitors or micro-batteries, providing:

-

Fast charging (within seconds),

-

Long cycle life (>10,000 cycles),

-

High areal capacitance (~150–300 mF/cm²).

These textile supercapacitors are made by coating SWCNTs onto woven or knitted substrates, separated by solid or gel electrolytes.

They can store power generated by TENGs or TEGs, enabling continuous energy supply for wearable electronics.

Example:

An SWCNT-coated cotton fabric supercapacitor maintained 92% capacity retention after 5000 bending cycles, demonstrating remarkable durability for real-world use.

4. Integrating SWCNT Smart Textiles into Wearable Systems

Design Approaches

SWCNTs can be used in multiple structural configurations:

-

Core–sheath fibers: SWCNTs as the conductive core, polymer as the flexible shell.

-

Layered fabrics: Alternating SWCNT and polymer layers for multifunctional behavior.

-

Printed circuits: SWCNT inks patterned into sensors, electrodes, and energy storage units.

Integration with Electronics

By combining SWCNT fabrics with low-power circuits, wearables can achieve:

-

Continuous biometric monitoring (ECG, EMG, sweat sensors).

-

Wireless power transfer between clothing components.

-

Self-charging systems that eliminate the need for external batteries.

Examples in Practice

-

Sportswear: Energy-harvesting shirts that power heart-rate monitors during exercise.

-

Healthcare textiles: Fabrics that record muscle activity or hydration levels.

-

Military and rescue uniforms: Smart gear that powers communication devices in remote environments.

5. Advantages of SWCNTs Over Other Conductive Materials

| Material | Conductivity | Flexibility | Durability | Cost Trend | Key Limitation |

|---|---|---|---|---|---|

| ITO (Indium Tin Oxide) | High | Low | Brittle | High | Cracks under bending |

| Silver nanowires | Excellent | Moderate | Corrosion | Moderate | Oxidation |

| Graphene | High | High | Moderate | Decreasing | Processing difficulty |

| SWCNTs | High | Excellent | Outstanding | Falling rapidly | Dispersion control |

SWCNTs stand out for their balance between conductivity and mechanical resilience, particularly for applications that demand both elasticity and long-term durability.

6. Challenges in SWCNT Smart Textiles

Despite impressive performance, several challenges must be overcome for large-scale commercialization:

| Challenge | Description | Current Approach |

|---|---|---|

| Uniform dispersion | SWCNTs tend to bundle due to van der Waals forces. | Use surfactants or covalent functionalization. |

| Wash durability | Conductivity may degrade after repeated washing. | Apply polymer encapsulation or crosslinking. |

| Cost scalability | High-purity SWCNTs remain expensive. | CVD production and purification advancements are lowering costs. |

| Integration with existing textile manufacturing | Requires compatibility with weaving, dyeing, and finishing processes. | Develop printable or spinnable SWCNT inks. |

7. Environmental and Health Considerations

While SWCNTs are generally chemically stable and inert, research continues to evaluate their biocompatibility and long-term exposure effects.

Encapsulation within polymer matrices or fabrics minimizes direct contact, ensuring safe use in consumer products.

Additionally, SWCNT-based smart textiles align with sustainability goals by:

-

Reducing battery waste,

-

Utilizing renewable body or ambient energy, and

-

Enabling recyclable electronic fabrics.

8. Future Outlook

The future of SWCNT-enabled smart textiles is exceptionally bright, with ongoing research targeting:

-

Hybrid nanocomposites combining SWCNTs with graphene or MXenes for improved energy density.

-

Stretchable electronic fabrics with integrated sensing, storage, and communication.

-

Self-powered wearable networks that operate without external charging.

By 2032, analysts project that the smart textile market will exceed USD 10 billion, with carbon nanotube materials accounting for a growing share of high-performance energy-harvesting systems.

Single-Walled Carbon Nanotubes (SWCNTs) have transformed the vision of wearable technology — from clothing that merely reacts to the environment to textiles that generate and store their own energy.

Through their combination of conductivity, flexibility, and nanoscale robustness, SWCNTs enable self-sufficient, comfortable, and durable energy fabrics for the next generation of wearables.

From athletic apparel to medical sensors and defense gear, SWCNT-integrated smart textiles are leading the way toward a truly energy-autonomous future.

With continued progress in scalable SWCNT manufacturing and textile integration, the age of self-powered smart clothing is not a dream — it’s already being woven.