Functionalization of CNTs – Enhancing Compatibility and Performance

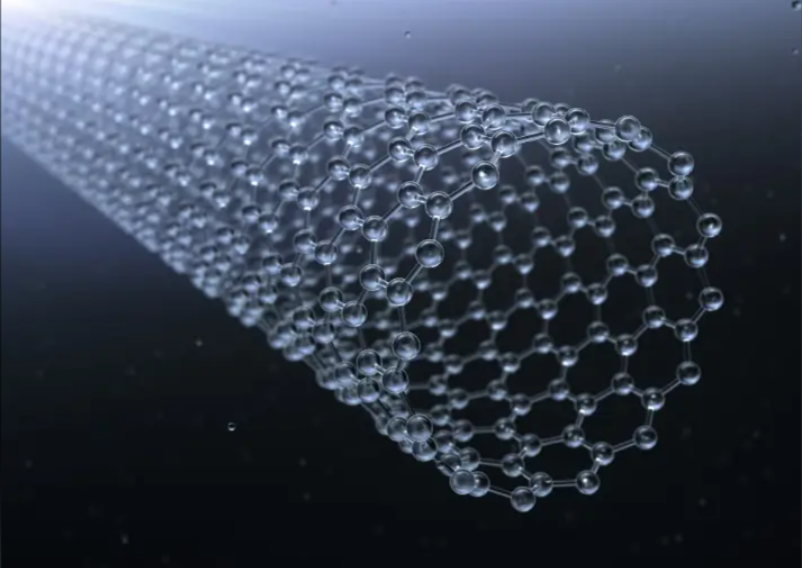

Carbon nanotubes (CNTs) have earned their reputation as one of the most powerful nanomaterials ever developed — combining extraordinary strength, conductivity, and aspect ratio in a single structure. Yet, despite these remarkable properties, their real-world adoption has often been limited by poor dispersibility and compatibility with other materials.

This is where functionalization becomes crucial. By chemically or physically modifying the surface of CNTs, engineers can tailor their interfacial behavior, chemical affinity, and processability for a wide range of applications — from polymer composites to energy storage and electronics.

This article explores why and how CNT functionalization works, the main methods, key challenges, and the market opportunities that functionalized CNTs are unlocking across industries.

Why Functionalize Carbon Nanotubes?

Pristine CNTs are hydrophobic and tend to aggregate due to strong van der Waals forces, forming bundles or entangled networks that limit their effective surface area. This aggregation drastically reduces their performance in composites or dispersions.

Functionalization introduces chemical or physical modifications that improve:

-

Dispersion in solvents or matrices

-

Chemical bonding with polymers, metals, or ceramics

-

Wettability and processability

-

Electrical and thermal interface stability

-

Mechanical load transfer efficiency

In short: functionalization makes CNTs engineerable materials rather than just exotic nanostructures.

Types of Functionalization

Functionalization can be broadly classified into two main categories — covalent and non-covalent — each with its own advantages, challenges, and use cases.

1️⃣ Covalent Functionalization

Covalent methods introduce new chemical groups directly onto the CNT surface by forming strong covalent bonds between the nanotube carbon atoms and functional molecules.

Typical Reactions:

-

Oxidation – Using nitric or sulfuric acid to create carboxyl (-COOH), hydroxyl (-OH), or carbonyl (-C=O) groups.

-

Amidation & Esterification – Attaching polymers, amines, or surfactants to improve matrix bonding.

-

Silane coupling – Grafting silane molecules to improve compatibility with epoxy or silicone matrices.

Advantages

-

Permanent surface modification

-

Improved interfacial strength with polymers and ceramics

-

Enhanced hydrophilicity and dispersion

Disadvantages

-

May damage CNT sidewalls and reduce conductivity

-

Complex reaction control needed for consistency

Applications

-

Polymer composites (epoxy, nylon, PEEK)

-

Battery electrodes

-

Coatings and adhesives

2️⃣ Non-Covalent Functionalization

Non-covalent methods preserve CNT structure by adsorbing or wrapping molecules around the nanotube surface, avoiding disruption of its conjugated π-bond system.

Typical Strategies:

-

Surfactant adsorption (e.g., SDS, CTAB, Triton X-100)

-

Polymer wrapping (e.g., PVP, PEG, polystyrene)

-

π–π stacking with aromatic molecules (e.g., pyrene derivatives)

Advantages

-

Maintains intrinsic electrical and mechanical properties

-

Simple, scalable processes (often in aqueous systems)

-

Reversible and tunable interactions

Disadvantages

-

Weaker bonding, may desorb over time

-

Limited chemical stability under harsh conditions

Applications

-

Conductive inks and coatings

-

Transparent films

-

Energy storage slurries

Functional Groups and Their Effects

| Functional Group | Typical Introduction | Effect |

|---|---|---|

| -COOH / -OH | Acid oxidation | Improves hydrophilicity and dispersion |

| -NH₂ | Amination or amidation | Enhances bonding with epoxy or PU |

| -Si–O– | Silanization | Boosts compatibility with glass or ceramics |

| –SO₃H | Sulfonation | Increases ionic conductivity |

| Polymer chains (PEO, PVP) | Grafting or wrapping | Enhances processability and flexibility |

By selecting the right surface chemistry, CNTs can be made to disperse evenly in almost any matrix, from water-based slurries to high-temperature thermoplastics.

Processing Routes

| Method | Description | Typical Use |

|---|---|---|

| Acid Treatment | Oxidative attack using nitric/sulfuric acid | Creates carboxyl groups for polymer composites |

| Plasma Treatment | Low-temperature plasma introduces oxygen/nitrogen groups | Surface activation without acid waste |

| Grafting Polymer Chains | “Grafting-to” or “grafting-from” polymerization methods | Improves flexibility and melt processing |

| Electrochemical Functionalization | Uses electrochemical oxidation or reduction | Fine control over surface modification |

| Physical Adsorption | Surfactant or polymer wrapping | Simple dispersion stabilization |

Functionalization in Polymer Composites

Functionalized CNTs are widely used to reinforce polymer matrices. Properly dispersed and bonded CNTs can enhance:

| Property | Improvement |

|---|---|

| Electrical conductivity | Up to 10⁶ S/m (percolation threshold <1 wt%) |

| Thermal conductivity | 3–5× compared to base polymer |

| Tensile strength | +30–80% improvement |

| Modulus | +20–50% increase |

For example:

-

Epoxy–CNT composites use amino-functionalized CNTs to form covalent bonds, boosting mechanical and electrical performance.

-

TPU–CNT composites use hydroxyl-functionalized CNTs to improve elasticity and adhesion.

These composites find applications in ESD coatings, lightweight structures, thermal interface materials, and flexible electronics.

Functionalization for Energy Applications

Functionalized CNTs are key enablers in battery electrodes, supercapacitors, and fuel cells.

In Lithium-Ion Batteries (LIBs)

CNTs with carboxyl and hydroxyl groups improve dispersion in slurries and adhesion with binder systems (like PVDF or SBR), leading to:

-

Better electron pathways

-

Reduced impedance

-

Higher capacity retention

In Supercapacitors

Sulfonated or nitrogen-doped CNTs enhance electrolyte wettability and pseudocapacitance, improving both energy and power density.

In Fuel Cells

Functionalized CNTs act as durable catalyst supports with improved metal nanoparticle anchoring and oxidation resistance.

Functionalized CNTs in Coatings and Films

CNT functionalization also enables new categories of advanced coatings:

-

Antistatic and conductive paints

-

Corrosion-resistant coatings

-

Thermal management films

-

Infrared or EMI shielding layers

Hydrophilic functional groups help CNTs mix with waterborne resins, avoiding toxic solvents and supporting eco-friendly processing.

Challenges in CNT Functionalization

Despite its success, several challenges remain:

-

Controlling Degree of Functionalization – Excessive modification can damage the CNT structure and reduce performance.

-

Batch Consistency – Reaction conditions must be carefully standardized.

-

Purification – Removing acid residues and byproducts without damaging CNTs.

-

Scalability – Maintaining quality during large-scale production.

-

Cost–Performance Balance – Avoiding excessive treatment steps that raise cost.

Industrial players now focus on mild plasma and electrochemical functionalization, which are scalable and environmentally cleaner alternatives to wet acid processes.

Market Outlook (2025–2030)

| Sector | Application | CAGR (2025–2030) |

|---|---|---|

| Polymer composites | Automotive, aerospace, electronics | 21% |

| Energy storage | Batteries, supercapacitors, fuel cells | 27% |

| Coatings & inks | ESD and EMI shielding coatings | 25% |

| Textiles & films | Smart fabrics, wearable devices | 20% |

Functionalized CNTs are becoming standard additives for next-generation composite and energy materials. The total global market for CNT-based functional materials is projected to exceed USD 2.5 billion by 2030, driven by the shift toward sustainable and lightweight solutions.

Future Directions

-

Green functionalization using plasma or enzymatic systems

-

Hybrid nanostructures combining CNTs with graphene or MXene

-

Smart interfaces with adaptive conductivity or self-healing capability

-

Customized functionalization for specific polymer chemistries

As material integration deepens, functionalized CNTs are becoming a platform technology, bridging nanomaterials with real-world products — from EV batteries to flexible sensors.

Functionalization transforms carbon nanotubes from challenging nanomaterials into versatile industrial components. Through controlled surface chemistry, CNTs can achieve high compatibility, superior dispersion, and enhanced performance across structural, electrical, and energy systems.

Functionalized CNTs = Real-world CNTs.

Their adaptability makes them one of the most exciting enablers of the coming decade’s advanced materials revolution.

📩 Interested in Functionalized CNTs or Custom Nanocomposite Development?

We offer:

-

Functionalized CNT powders & dispersions

-

Polymer-CNT composite formulations

-

Customized surface chemistry development

→ Contact Our Engineering Team for Technical Consultationhttps://graphenerich.com/about-us/contact-us/