CNT Reinforced Composites – How They Improve Strength and Toughness

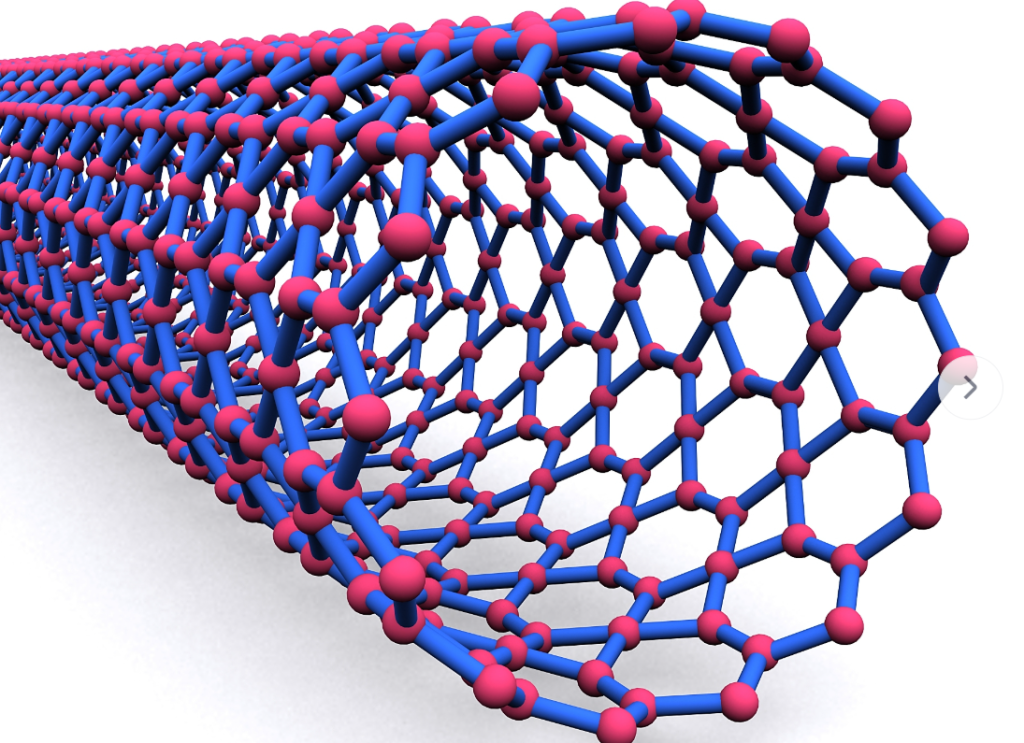

Carbon nanotubes (CNTs) have revolutionized the field of materials engineering due to their exceptional mechanical, thermal, and electrical properties. Among the most promising applications is their use as reinforcing agents in composite materials, where CNTs enhance both strength and toughness, enabling lightweight yet durable structural components.

This article explores the mechanisms behind CNT reinforcement, the types of composites that benefit from CNTs, and practical applications in industries ranging from aerospace to construction.

1. Introduction to CNT Reinforced Composites

CNT reinforced composites are materials in which carbon nanotubes are incorporated into a polymer, metal, or ceramic matrix to improve mechanical performance. Even at low weight fractions (0.1–5%), CNTs can dramatically enhance:

-

Tensile strength

-

Fracture toughness

-

Impact resistance

-

Fatigue life

The key advantage is that CNTs provide nanoscale reinforcement, bridging the gap between molecular-level strength and macroscopic structural performance.

2. Why CNTs Are Effective Reinforcements

Carbon nanotubes exhibit unique properties:

| Property | Typical Value | Benefit in Composites |

|---|---|---|

| Tensile strength | 50–100 GPa | High load-bearing capacity |

| Young’s modulus | 1–1.2 TPa | Stiffness enhancement |

| Aspect ratio | 100–10,000 | Efficient stress transfer |

| Density | ~1.3–1.4 g/cm³ | Lightweight reinforcement |

| Thermal conductivity | 3,000–3,500 W/m·K | Heat dissipation in composites |

CNTs’ high aspect ratio allows them to form percolating networks within the matrix, transferring stress effectively and resisting crack propagation. Their nanoscale diameter enables them to interact directly with polymer chains or metal grains, enhancing mechanical performance without significantly increasing weight.

3. Types of CNT Reinforced Composites

3.1 Polymer Matrix Composites (PMCs)

-

CNTs are dispersed in thermoplastics (e.g., PE, PP, PEEK) or thermosets (e.g., epoxy, polyester).

-

Benefits:

-

Tensile strength increase up to 30–50% at low CNT loading

-

Improved fracture toughness

-

Electrical conductivity for anti-static or EMI shielding applications

-

-

Applications: Aerospace panels, automotive structural parts, sporting goods, wearable devices.

3.2 Metal Matrix Composites (MMCs)

-

CNTs embedded in metals like aluminum, copper, or titanium.

-

Benefits:

-

Increased hardness and wear resistance

-

Improved fatigue life

-

Enhanced thermal conductivity

-

-

Applications: Heat sinks, engine components, aerospace structures.

3.3 Ceramic Matrix Composites (CMCs)

-

CNTs reinforce alumina, silicon carbide, or zirconia ceramics.

-

Benefits:

-

Increased fracture toughness (resistance to brittle failure)

-

Thermal shock resistance

-

Crack deflection and bridging

-

-

Applications: Cutting tools, high-temperature structural components, protective coatings.

4. Reinforcement Mechanisms

CNTs improve strength and toughness through several mechanisms:

4.1 Load Transfer

CNTs act as nanoscale fibers that carry stress from the matrix, reducing localized strain and improving composite strength.

4.2 Crack Bridging

When a crack forms, CNTs bridge the gap, slowing crack propagation and increasing fracture toughness.

4.3 Pull-Out and Sliding

CNTs can pull out or slide under stress, dissipating energy and enhancing impact resistance.

4.4 Matrix Interaction

Functionalized CNTs can form strong interfacial bonds with polymers or metals, improving adhesion and load transfer efficiency.

4.5 Network Formation

High-aspect-ratio CNTs can form percolating networks, distributing stress more evenly and preventing catastrophic failure.

5. Processing Techniques

The dispersion of CNTs is critical for maximizing reinforcement. Common processing methods include:

5.1 Solution Mixing

-

CNTs dispersed in a solvent with the polymer, followed by casting or extrusion.

-

Advantages: Good dispersion at low loading, suitable for thermoplastics and thermosets.

5.2 Melt Blending

-

Polymer is melted and CNTs are mechanically mixed.

-

Advantages: Industrially scalable for thermoplastics; no solvent needed.

-

Challenge: Achieving uniform dispersion without CNT aggregation.

5.3 In-Situ Polymerization

-

CNTs are added during polymerization.

-

Advantages: Strong interfacial bonding and better CNT alignment.

5.4 Powder Metallurgy (for MMCs)

-

CNTs mixed with metal powders, then sintered or hot-pressed.

-

Advantages: Produces dense, mechanically robust composites.

5.5 Sol-Gel and Ceramic Processing

-

CNTs incorporated during sol-gel synthesis or mixed with ceramic powders.

-

Benefits: Maintains CNT integrity in high-temperature ceramics.

6. Key Performance Metrics

| Metric | Improvement with CNTs | Notes |

|---|---|---|

| Tensile Strength | +20–50% | Depends on CNT type, dispersion, and loading |

| Young’s Modulus | +10–30% | More pronounced in aligned CNT composites |

| Fracture Toughness | +50–100% | Crack bridging and pull-out mechanisms |

| Fatigue Life | +30–80% | Better stress distribution and energy dissipation |

| Thermal Conductivity | +50–200% | Useful in thermal management applications |

| Electrical Conductivity | Up to 10⁴ S/m | Enables EMI shielding and antistatic properties |

Even low CNT loadings (<5 wt%) can achieve significant improvements, making them ideal for weight-sensitive applications.

7. Applications Across Industries

7.1 Aerospace and Automotive

-

Lightweight CNT composites reduce fuel consumption while maintaining structural integrity.

-

Use cases: Fuselage panels, car body parts, battery enclosures.

7.2 Sporting Goods

-

Tennis rackets, bicycles, and golf clubs benefit from high strength-to-weight ratio and vibration damping.

7.3 Electronics and Energy

-

CNT reinforced polymer composites enhance thermal management in electronics.

-

Used in battery casings, heat spreaders, and EMI shielding layers.

7.4 Construction Materials

-

CNT composites in concrete or polymer-based building materials improve toughness, crack resistance, and durability.

-

Applications: High-performance flooring, protective panels, lightweight structural components.

7.5 Medical Devices

-

CNT reinforced polymers are used for prosthetics, implants, and orthopedic devices due to strength, toughness, and biocompatibility.

8. Challenges and Considerations

Despite advantages, CNT reinforced composites face technical challenges:

8.1 Dispersion and Agglomeration

-

Poor CNT dispersion reduces reinforcement efficiency.

-

Solution: Ultrasonication, surfactants, or functionalization.

8.2 Alignment

-

Random CNT orientation limits tensile strength improvements.

-

Solution: Shear alignment, magnetic or electric field-assisted alignment during processing.

8.3 Cost and Scalability

-

High-quality CNTs are expensive.

-

Scaling production while maintaining performance remains a key industrial challenge.

8.4 Interface Adhesion

-

CNT-matrix bonding is critical. Functionalization can improve adhesion but may alter CNT properties.

9. Future Trends

9.1 Hybrid Nanocomposites

-

Combining CNTs with graphene, nanoclay, or metallic nanowires to achieve synergistic reinforcement.

9.2 3D Printing of CNT Composites

-

Additive manufacturing enables complex geometries with CNT reinforcement, suitable for aerospace and biomedical applications.

9.3 Smart and Multifunctional Composites

-

CNTs provide conductivity and sensing capability while reinforcing the material, enabling self-monitoring structural components.

9.4 Eco-Friendly and Recyclable Composites

-

Research is ongoing to produce thermoplastic CNT composites that are easier to recycle without losing mechanical properties.

CNT reinforced composites are transforming material engineering by combining high strength, toughness, and multifunctionality in lightweight form factors.

Through efficient stress transfer, crack bridging, and network formation, CNTs enable polymers, metals, and ceramics to perform beyond traditional limits.

From aerospace panels to high-performance sporting goods and durable construction materials, CNT composites offer a versatile and high-performance solution for modern engineering challenges.

Future advancements in dispersion, alignment, and multifunctional integration will further expand CNT composites’ adoption, making them central to next-generation structural and functional materials.